Share this

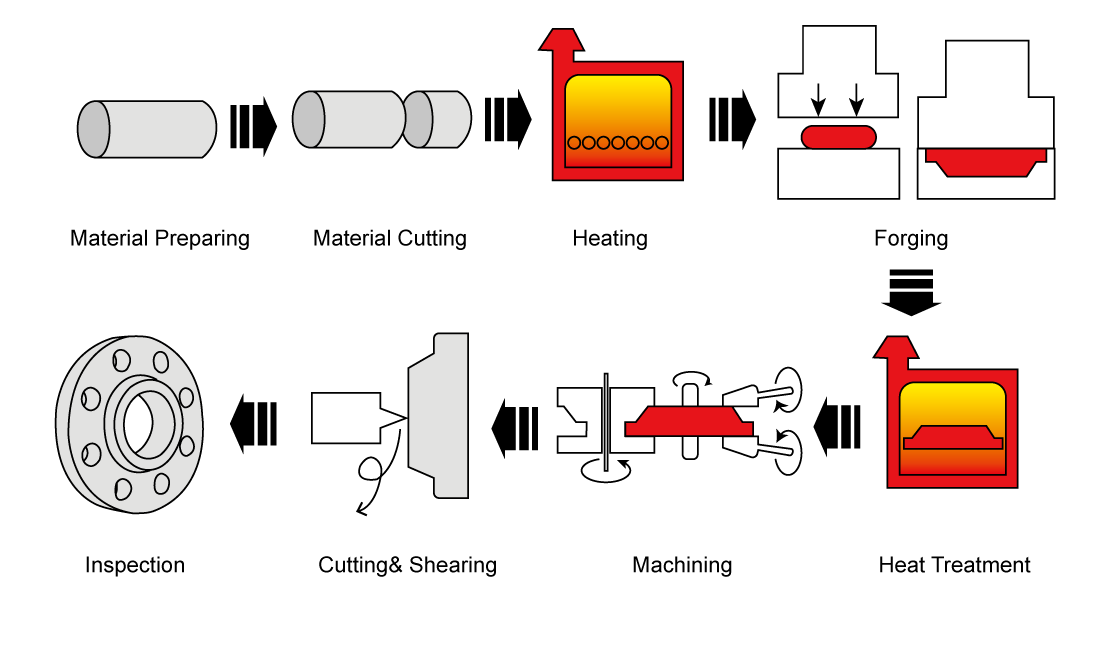

The process of manufacturing flanges involves the following steps:

1.Material Selection:

First, select the appropriate material for making the flange, typically using materials such as carbon steel, stainless steel, cast iron, etc. Material selection should consider the characteristics of the pipeline or equipment and the operating environment.

2. Design and Specifications:

Based on the requirements of the pipeline or equipment, design the dimensions, shape, and specifications of the flange. The design of the flange should adhere to relevant standards such as ASME B16.5 or EN 1092.

3. Material Cutting:

Use the appropriate cutting tools to cut the selected material into the required shape and dimensions for the flange.

4. Machining and Processing:

Process the edges of the flange to ensure they are flat and parallel. This typically includes cutting, milling, and trimming.

5. Hole Machining:

Depending on the number and location of bolt holes or connection holes on the flange, use a drilling machine or machining center to create these holes.

6. Surface Machining:

Machine the sealing surfaces of the flange to ensure flatness and smoothness for effective sealing. This step is typically done using a lathe or grinder.

7. Inspection and Quality Control:

Conduct rigorous quality control and inspections throughout the manufacturing process to ensure that the flange meets design specifications and standards.

8. Rust and Corrosion Protection:

Apply rust and corrosion protection to the flange based on the material and the operating environment to extend its service life.

9. Marking and Identification:

Mark relevant information on the flange, such as the material, specifications, manufacturing date, and other necessary details.

10. Packaging and Storage:

Properly package the finished flanges to prevent damage and store them in a dry and clean environment.

11. Delivery and Installation:

Finally, the flanges are delivered to the customer and installed on pipelines, valves, or equipment to ensure proper functionality.

Please note that the specific flange manufacturing process may vary depending on the material and specifications. Manufacturing flanges requires strict quality control and compliance with relevant standards to ensure their reliability and safety within a piping system. Flange manufacturers typically develop manufacturing processes based on specific project requirements and standards.