experience to be trusted

about us

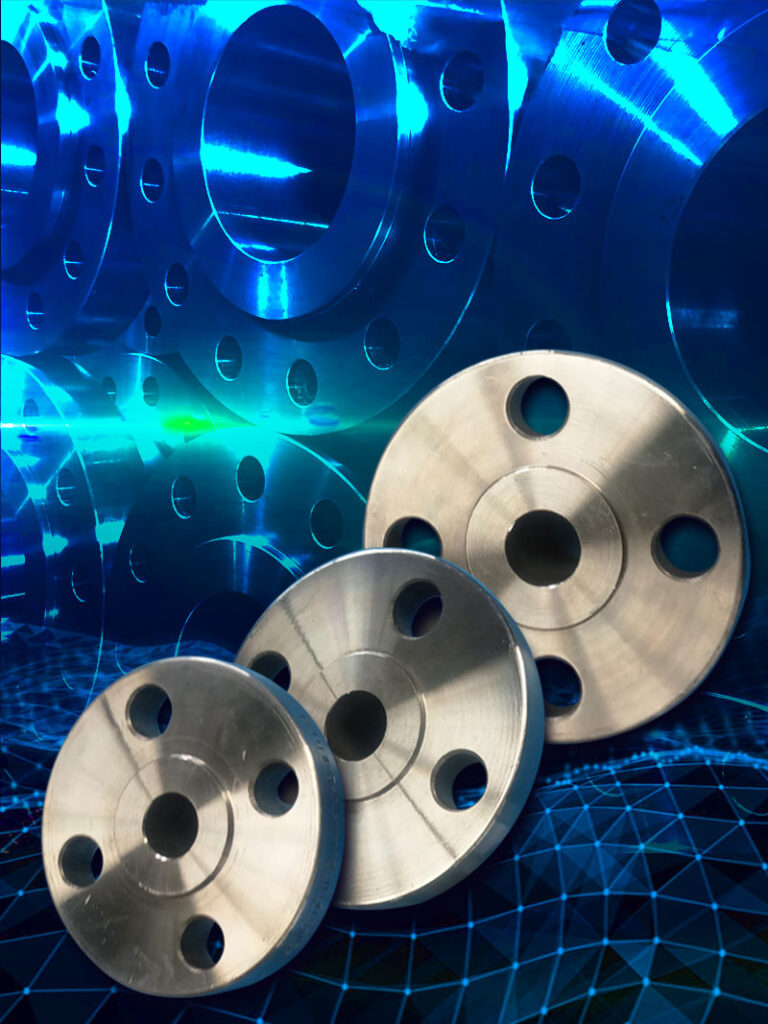

We are a professional flange manufacturer and overall solution provider

What makes us standout

advanced manufacturing equipment

Possess the world’s most advanced production technology and production line

Strict quality management system

Strict quality management process to ensure products meet customer needs

After-sales service

7X24 hours service Professional and technical personnel guidance

worldwide reach

OUR QUALITY

Elite Flange have stringent Quality Management and Control System to ensure the superior quality of products. All of our products are strictly inspected at each stage of the production process from the Inspection of Raw Material to the finish products. Each order is carried out as per Inspection / Test Plan, Required Specifications and Applicable Manufacturing / Quality Standards.

- ASTM A105

- ASTM A694

- ASTM A350

- ASTM A182

- ASME B564

Manufacturing Equipment

Inspections in manufacturing Process

Elite Flange Material Inspections are carried out as follows:

MATERIAL RECEIVING INSPECTIONS

1. DIMENSIONAL INSPECTION

2. VISUAL INSPECTION

3. MATERIAL IDENTIFICATION

IN-PROCESS INSPECTIONS

1.VISUAL INSPECTION

2.DIMENSIONAL & SHAPE INSPECTION

3.HARDNESS TEST

4.PROCESSING CONDITIONS CHECK

FINAL INSPECTIONS

1. VISUAL INSPECTION

2. DIMENSIONAL INSPECTION

3.NON-DESTRUCTIVE EXAMINATIONS

4.CERTIFICATION & MECHANICAL TESTS

5.THIRD-PARTY INSPECTIONS

TESTING FACILITIES

Non Destructive Testing

Ultrasonic Testing

Ultrasonic testing techniques are widely accepted for quality control and materials testing in many industries.

Magnetic Parcile Testing

MT is applicable to all metals which can be strongly magnetised – ferritic steels and irons, but not generally austenitic steels.Such as alloy steel, carbon steel and low temperature steel.

Penetrant Testing

PT is a simple low-cost method of detecting surface-breaking flaws such as cracks, laps, porosity, etc. To be detected, the flaw must reach the surface to be tested.

ELITE FLANGES