Share this

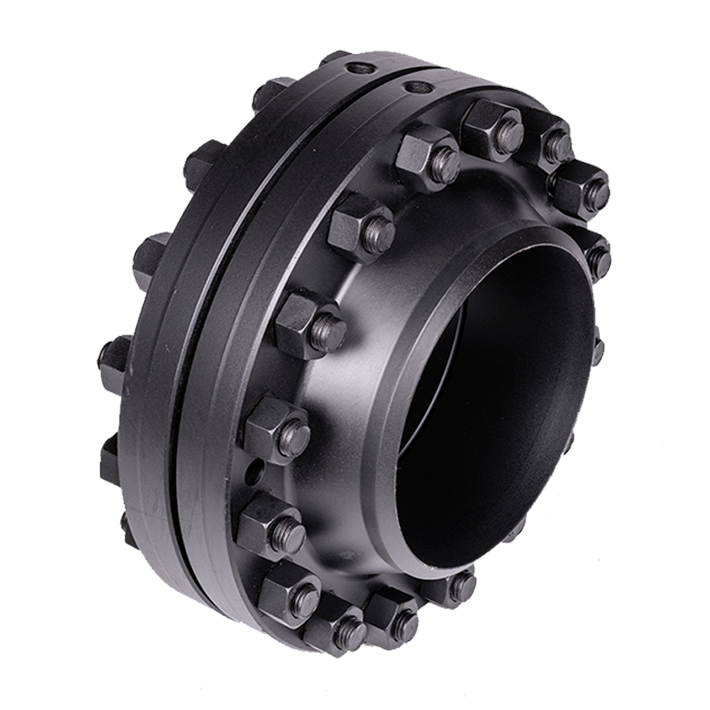

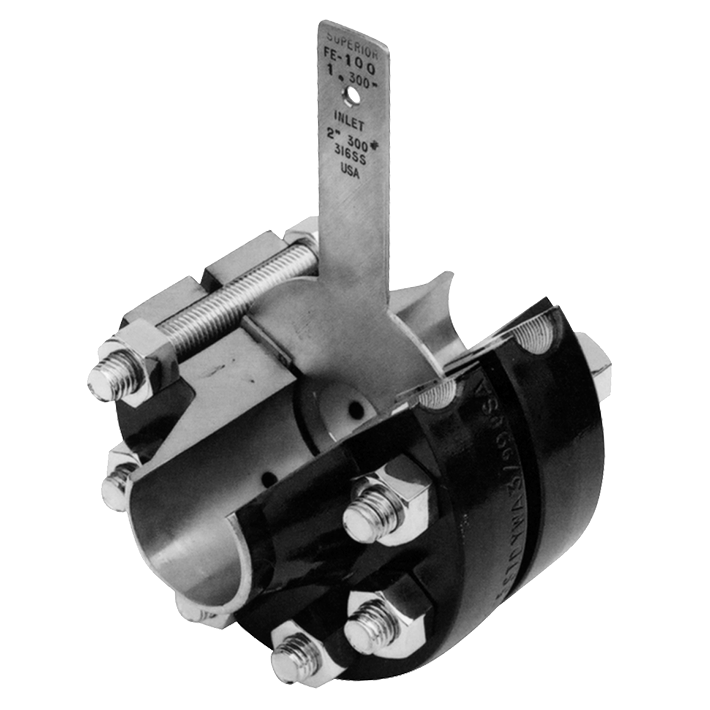

Orifice flanges are usually applying for metering the volumetric flow rate of liquids and gasses through a pipe. Two orifice flanges are called an orifice flange union. Each flange comes with two pipe taps for measuring the pressure drop of the flow through an orifice plate. Orifice plates do not come with the flanges and are sized based on the requirements of the process. Two jack screws are used to spread the flanges apart in order to change the orifice plate. This flange is normally available in weld neck, slip-on, and threaded flanges. Orifice flanges generally have a raised face.

Molding Process:

Through forging process, using mold forming, and then through machining to complete the product processing.

Production Scope:

3/8”-80”

Main Material:

ASTM A105 20# Q235 SS400 Q345

Application Condition:

Widely used in Petrochemical, Coal Chemical, Refining, Oil and Gas Transmission, Marine Environment, Power, Heating and Other projects

Product Characteristics:

Standard: ANSI/ASME B16.5 B16.47 B16.48 API.

DIN2573 2576 2577 2527 2502-2503 DIN 2633 -2637.

JIS B2220 GOST 12820 SABS.

BS4504 EN 1092 HG20592.

JB GB.

American Series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500.

Surface: FF, RF, MFM, TG, RJ.

Rich production technology, advanced equipment, high automation degree and high production precision,complete molding.As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC,company has won numbers of national, province reputation

For pipe fittings, please link: https://bekingpiping.com