Share this

Introduction: In the world of piping and construction, flanges play an essential role in creating strong, durable connections between pipes. The material used for flanges and their inspection processes are critical to ensuring the safety and performance of any pipeline system. Whether you’re working in the oil and gas industry, chemical processing, or even in HVAC systems, understanding the importance of flange materials and flange inspection is paramount to maintaining reliability and efficiency in your operations.

Key Features of Flanges: Flanges are available in various types and materials, each suited to different applications. Depending on the nature of the project, factors such as pressure, temperature, and environmental conditions must be considered. Common materials for flanges include:

- Carbon Steel Flanges – Widely used in industries that require strong and cost-effective solutions, carbon steel is known for its strength and resistance to general wear and tear.

- Stainless Steel Flanges – These flanges are ideal for environments where corrosion resistance is crucial. Stainless steel flanges are often used in food processing, pharmaceutical, and chemical industries.

- Alloy Steel Flanges – These offer a high resistance to heat and corrosion, making them perfect for extreme temperature conditions.

- Nickel Alloy Flanges – Best suited for very aggressive environments such as marine or high-temperature applications, nickel alloys are known for their excellent corrosion resistance.

- Ductile Iron Flanges – Known for their strength and ductility, these flanges are commonly used in municipal water and wastewater systems.

Flange Inspection: A Critical Step in Quality Assurance

Once the material is selected, ensuring that the flanges meet industry standards is essential to guaranteeing the safety and functionality of the system. This is where flange inspection comes into play. Inspection techniques can vary depending on the application but generally include the following:

- Visual Inspection – This is the first line of defense to check for any visible defects or irregularities in the flange. The surface should be free from cracks, pitting, and rust.

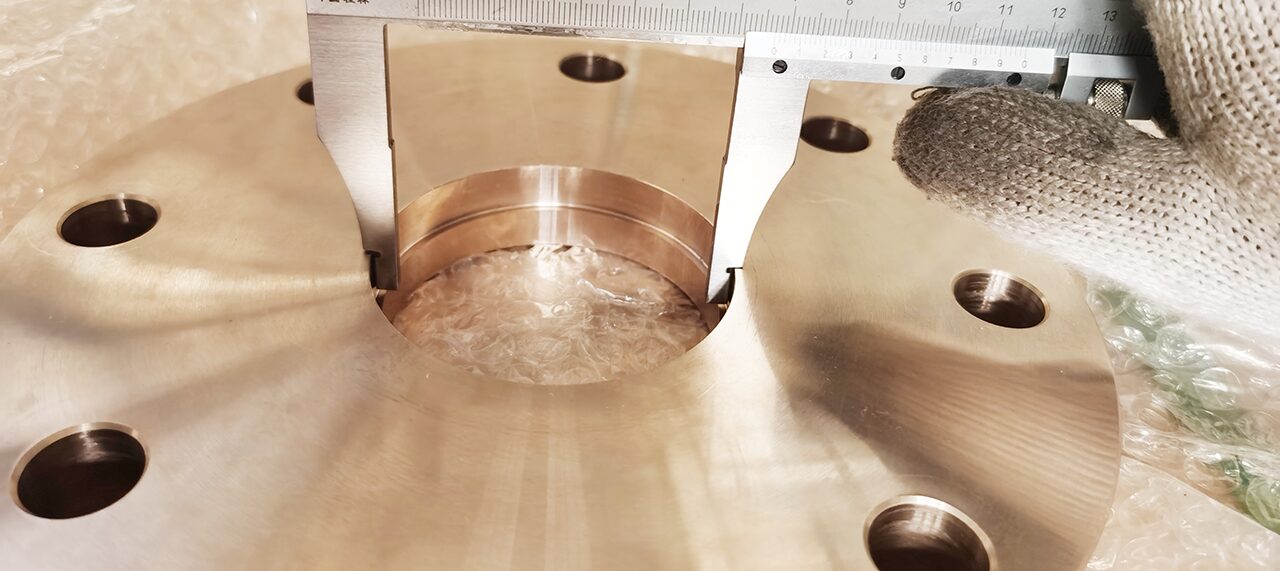

- Dimensional Inspection – Proper sizing is crucial for ensuring the flange fits perfectly with the pipe and maintains the integrity of the system.

- Material Verification – Ensuring the flange is made of the correct material as specified in the design is vital. Testing methods like spectrographic analysis or X-ray diffraction may be used.

- Pressure Testing – Flanges are sometimes subjected to pressure testing to ensure they can withstand the intended operating conditions without leaking or breaking.

- Ultrasonic Testing – Used to detect internal defects that may not be visible externally, this method helps identify hidden flaws that could lead to failure in the long run.

Flange Quality Control: Ensuring Longevity and Safety

The quality control of flanges is not a one-time process but a continuous effort that spans the manufacturing cycle. From selecting the right materials to conducting comprehensive inspection procedures, every step is crucial to maintaining the performance of the pipeline system. Rigorous inspections and the use of high-quality materials can ensure that flanges not only meet industry standards but also surpass client expectations.

Conclusion: When it comes to flanges, the material you choose and the inspection process you implement are vital to the overall success of your pipeline system. Quality materials combined with thorough inspections ensure that flanges are strong, durable, and capable of performing in the most demanding environments. Don’t compromise when it comes to the foundation of your pipeline system—choose quality flanges that are built to last.

Would you like to adjust or add any specific details or focus areas?