Share this

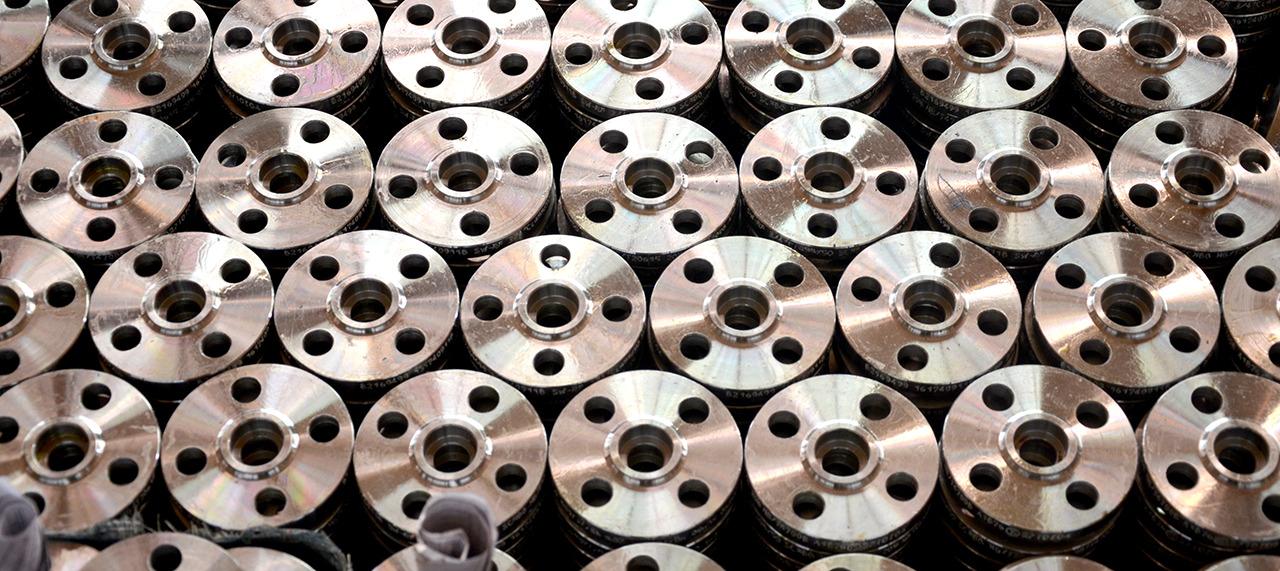

The main reason why stainless steel flat welding flanges are less susceptible to corrosion is related to the inherent properties of stainless steel. Here are some possible reasons:

1. Corrosion Resistance: Stainless steel is a metal alloy containing chromium and other elements. These elements form a dense oxide film, known as “passivation” or “stainless steel film.” This film prevents direct corrosion of the metal by oxygen, water, and other corrosive media, enhancing the corrosion resistance of stainless steel.

2. Corrosion-Resistant Alloy Elements: The alloying elements in stainless steel, particularly chromium and nickel, exhibit strong resistance to many corrosive substances. These elements contribute to maintaining the stability of stainless steel, making it less susceptible to corrosion by most corrosive media.

3. Surface Treatment: Stainless steel plates are often subjected to surface treatments such as polishing or acid cleaning to further enhance surface smoothness and corrosion resistance.

4. Design and Manufacturing Quality: Well-thought-out design and high-quality manufacturing ensure the sealing and stability of the flange, reducing the likelihood of corrosion.

It’s important to note that while stainless steel has excellent corrosion resistance, in certain extreme environments, corrosion may still occur. Therefore, when selecting materials and designing engineering projects, specific usage conditions and requirements need to be taken into consideration.