Share this

You can choose the appropriate industrial flanges according to your own needs. Elite Piping Manufacture can provide various types of industrial flanges for different purposes. Looking forward to your consultation with us!

About industrial flange

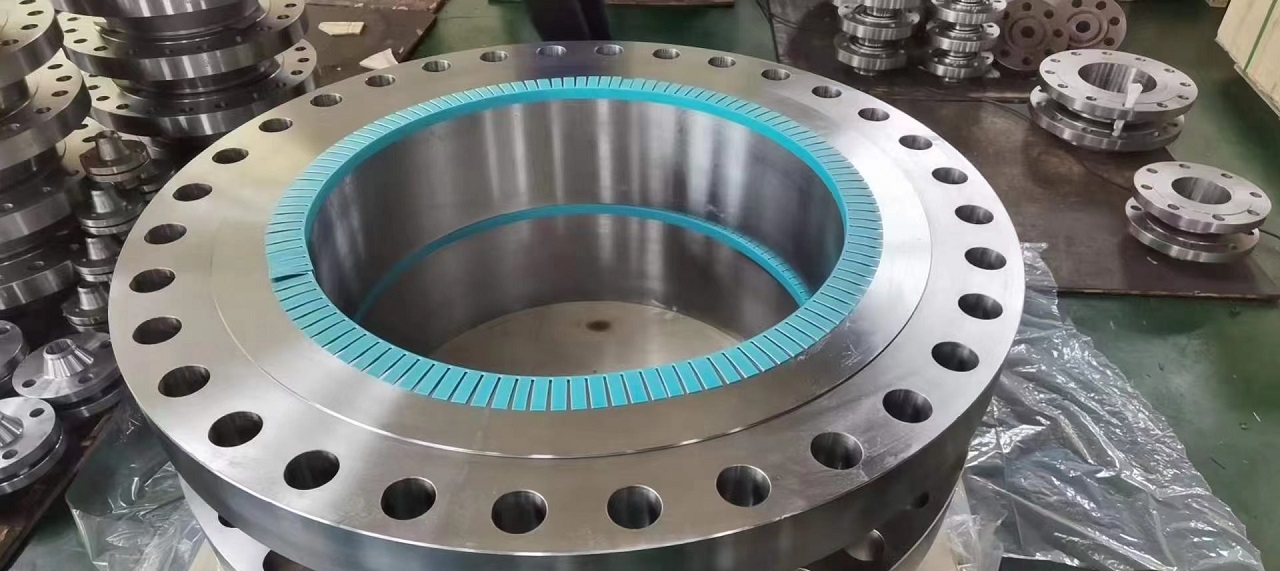

Industrial flange is a part that connects pipes to each other and is connected to the pipe end; it is also used as a flange on the inlet and outlet of equipment to connect two equipment. Flange connection or flange joint refers to a detachable connection that is composed of flanges, gaskets and bolts that are connected to each other as a set of combined sealing structures. Pipe flanges refer to the flanges used for piping in pipeline devices and are used in equipment The upper part refers to the inlet and outlet flanges of the equipment.

Industrial flange markings

The steel pipe outer diameter series is the basis of the pipe flange size. The steel pipes currently produced and used in our country are divided into two series according to their outer diameter: marked in the standard as “Series I” and “Series II”, or “A Series” and “B Series”. The steel pipes of series A are “imperial pipes”, commonly known as “large outer diameter pipes”; the steel pipes of series B are “metric pipes”, commonly known as “small outer diameter pipes”.

The so-called “large outer diameter pipe and small outer diameter pipe” means: under the condition of the same nominal diameter of the pipe, the outer diameter size of the steel pipe used in the pipe accessories (such as flanges, valves, pipe fittings and pipeline filters, etc.) Size, the larger size is called “large outer diameter” pipe; the smaller size is called “small outer diameter” pipe.

Classification of industrial flanges

According to different industry standards, flanges can be divided into different types, including integral flanges, threaded flanges, plate flat welding flanges, necked butt welding flanges, necked flat welding flanges, socket welding flanges, butt welding flanges Ring loose sleeve flange, flat welding ring loose sleeve flange, lined flange cover, etc. In the petrochemical industry standards, types such as loose flanges are also included. There are also corresponding types of flanges in the mechanical industry standards and national standards.

Industrial flange assembly

Before installing the flange, be sure to clean its surface, especially the sealing surface.

When assembling flat plate welding flanges, first ensure that the pipe end is inserted 2≤3 of the flange inner diameter thickness, and then perform spot welding of the flange and the pipe. For horizontal pipes, it is necessary to spot weld the flange from above, and then use a 90° angle ruler to check and correct the flange position from different directions to ensure that its sealing surface is perpendicular to the center line of the pipe. Finally, confirm whether the position of the second point under the spot weld is accurate.

Use a 90° angle ruler to check and correct the flange position from the left and right directions, and then spot weld the third and fourth points at the corrected positions to complete the spot welding and fixing of the flange.

When installing the flange, the bolt holes should be aligned with the corresponding bolt holes of the fixed flange and kept parallel. The deviation should be controlled within 1.5% of the outer diameter of each flange and should not exceed 2mm.

When selecting equipment or valve components, ensure that the flange size matches the flange connection size used in the pipeline. This is important because sizing mismatches can cause equipment installation problems and improper pipe connections.

Industrial flange connection

When connecting flanges, make sure they remain on the same axis and the bolt hole center deviation does not exceed 5% of the hole diameter. Additionally, the bolt should be able to pass freely through the hole. The specifications of the connecting bolts should be consistent and the installation direction should be the same. At the same time, the bolts need to be tightened symmetrically and evenly.

Angled washers of different thicknesses should not be used to compensate for flange non-parallelism. Double washers should also not be used. When large-diameter gaskets need to be spliced, flat ports should be avoided and instead angled laps or labyrinths should be used.

In order to facilitate the installation and disassembly of the flange, the distance between the fastening bolts and the flange surface shall not be less than 200 mm.

When tightening the bolts, a symmetrical and criss-crossing sequence is required to ensure even stress on the washers.

It is recommended to use molybdenum disulfide, graphite oil or graphite powder to coat bolts and nuts in the following situations: stainless steel, alloy steel bolts and nuts; pipes with design temperatures below 100°C or 0°C; used in open-air facilities; and in the presence of In environments with atmospheric corrosion or corrosive media. This will facilitate removal during future disassembly.

Metal washers such as copper, aluminum and mild steel should be annealed before installation.

The flange connections of buried pipelines must not be buried directly, but inspection wells must be installed. If burial is necessary, anti-corrosion measures must be taken.

Commonly used industrial flange soft gasket materials

The most commonly used industrial flange soft gasket materials include rubber sheets and rubber cotton sheets.

1.Industrial rubber sheet

Industrial rubber sheet, also known as industrial vulcanized rubber sheet or rubber sheet, is a commonly used material with a wide range of applications in industrial production.

- Rubber cotton board

Rubber wool sheets, also known as asbestos rubber sheets, are often used as sealing gaskets for equipment and pipe flanges. Its applicable media include water, steam, air, various gases, ammonia, alkali and oil, etc.

Common faults of industrial flanges

In the continuous production of modern industry, flanges are affected by media corrosion, erosion, temperature, pressure, vibration and other factors, and leakage problems will inevitably occur. Due to errors in the processing dimensions of the sealing surface, aging of the sealing components, improper installation and tightening, etc., it is easy to cause flange leakage. If the flange leakage problem cannot be treated in time, the leakage will expand rapidly under the erosion of the medium, causing material loss, damage to the production environment, causing the company to shut down and stop production, causing huge economic losses. If toxic, harmful, flammable and explosive media leaks, it may also cause major accidents such as poisoning of personnel, fire and explosion.

Solutions to industrial flange failures

The traditional method to solve flange leakage is to replace sealing elements and apply sealant or replace flanges and pipes. However, this method has great limitations, and some leaks are restricted by the safety requirements of the working environment and cannot be solved on site. . Polymer composite materials can now be used for on-site plugging, among which the relatively mature system of Fushilan is used. It is an ideal method, especially in flammable and explosive situations, and shows its unique advantages. The construction process of polymer composite material technology is simple, safe and low-cost. It can solve most of the flange leakage problems for enterprises, eliminate safety hazards and save more maintenance costs for enterprises.

The above is an introduction to our company’s industrial flanges. If you have any questions, you are welcome to communicate with us.