Share this

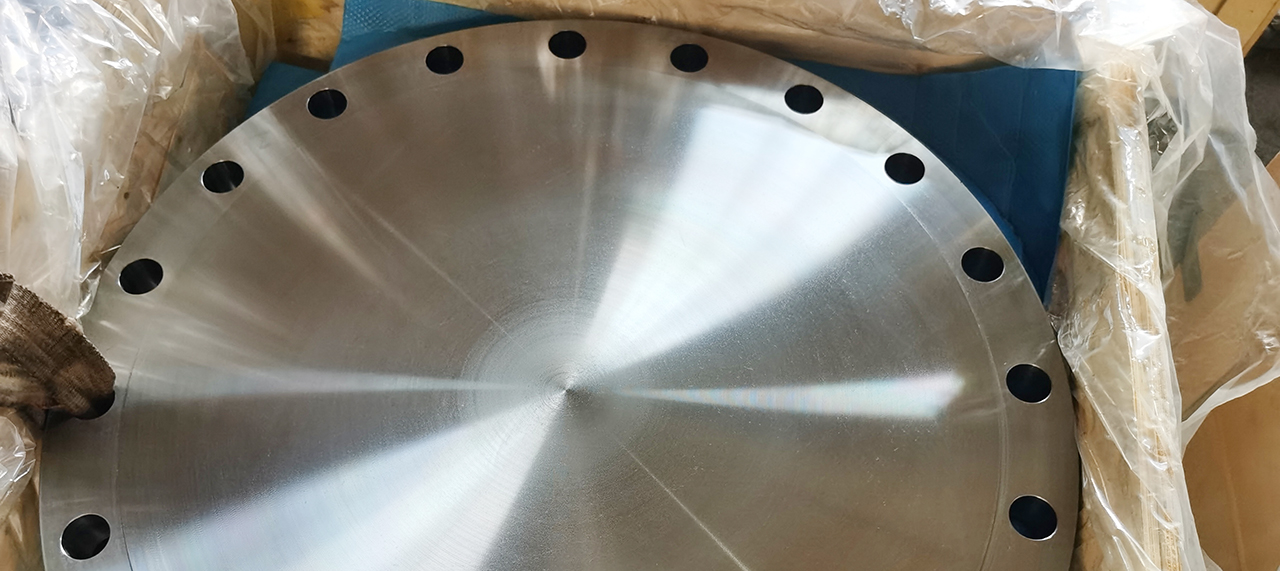

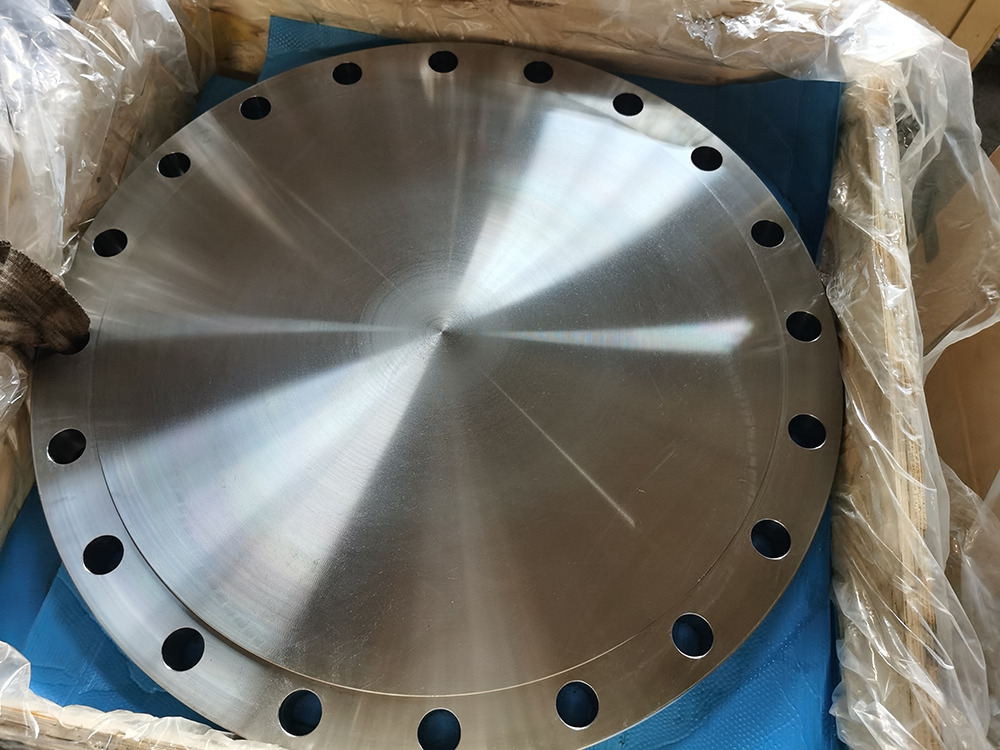

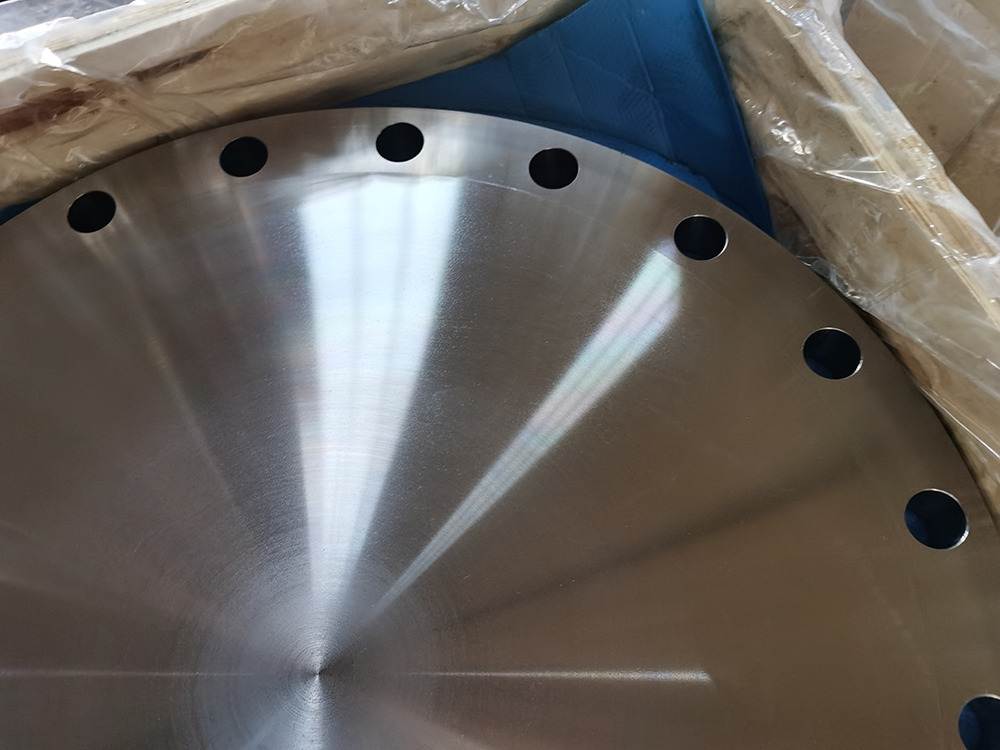

Flanges are usually coated with a layer of anti-rust oil before leaving the factory, which is to protect the surface of the flange from oxidation and corrosion. Anti-rust oil can form a protective layer to block the metal surface of the flange from contact with moisture and oxygen in the air, thereby reducing the oxidation reaction and corrosion of the metal.

This anti-rust oil is usually a temporary coating that can be easily removed before the flange is installed or used. Before installing the flange, it is usually necessary to wipe off the anti-rust oil from the flange surface with an appropriate method to ensure the quality and safety of the connection.

The anti-rust oil can also protect the flange during storage, preventing unnecessary corrosion and damage during storage. This helps to ensure that the flange is still in good condition when delivered to the end user.

In general, anti-rust oil is applied to prolong the service life of the flange, protect its surface, and prevent damage caused by corrosion and oxidation.