Share this

A Comprehensive Guide to Boiler Piping: Your Reliable Piping Supplier in China – Elite Piping Manufacture Co., Ltd.

Introduction

Boiler tubes are critical components in the infrastructure of many industrial applications, including power generation, petrochemical, and oil and gas industries. As a leading pipe manufacturer in China, Elite Piping Manufacture Co., Ltd is proud to offer high-quality boiler pipes that meet international standards and ensure reliable performance even in the most demanding environments.

In this comprehensive guide, we will explore the different types of boiler tubing, their uses, and the benefits of working with Elite Piping Manufacture Co., Ltd for all your plumbing needs. Whether you’re looking for fire tube boilers or other types of boiler tubes, our expertise and quality products will ensure your operation runs smoothly and efficiently.

What are boiler tubes?

Boiler tubes are tubes used to produce steam by heating water through combustion processes in industrial boilers. They are important components of boilers that play a decisive role in the heat exchange process. Boiler tubes are usually made of high-quality steel to withstand high pressure and temperature.

Types of boiler pipes

- Fire boiler pipes :

- In boilers, hot gases pass through tubes surrounded by water. The heat of the gases passes through the walls of the pipes into the water, creating steam.

- Advantages : simplicity of design, easy maintenance and cost efficiency.

- Water pipe boiler pipes :

- In water tube boilers, water flows through the tubes and is heated by external combustion gases. This type is usually used in high pressure applications.

- Advantages : Higher efficiency, better heat transfer and ability to withstand higher pressure and temperature.

Boiler tube applications

Boiler tubes are used in a variety of industries, including:

- Power generation : Essential for generating steam in power plants.

- Oil and Gas : Used for process heating in oil refineries and petrochemical plants.

- Industrial production : the integral operation of many production processes.

- Shipbuilding : Used in marine boilers to power ships and other deck applications.

Why choose Elite Piping Manufacture Co., Ltd for boiler pipes?

As a leading pipe supplier in China, Elite Piping Manufacture Co., Ltd offers many advantages that make us the preferred choice for your boiler piping needs:

- Improved production capabilities

Our modern manufacturing facility covers an area of 100,000 square meters and is equipped with 280 advanced machines. This enables us to produce high quality boiler tubes that meet various international standards including ANSI, ISO, API, JIS, DIN, BS, MSS and GOST.

- Skilled workforce

Our strong technical staff includes 380 employees, including 122 professionals, 16 senior engineers and 28 engineers. This team of experts ensures the accuracy of each product and can handle even the most complex projects.

- Versatile expertise in materials

We manufacture boiler tubes in a variety of materials including carbon steel, alloy steel, special alloy, stainless steel, duplex and super duplex. This diversity ensures that we can meet the specific needs of different industries and applications.

- Commitment to quality

Quality is at the heart of what we do. Our commitment to quality has earned us an enviable reputation and enables us to deliver products that meet or exceed our customers’ expectations. We employ strict quality control measures throughout the manufacturing process to ensure the highest standards.

- Global reach

We export our products to more than 25 countries around the world. Our global presence is a testament to our customers’ trust and confidence in our products and services. We understand the international market and are equipped to meet global standards and requirements.

- Customized solutions

We understand that every customer has unique requirements. Our ability to manufacture non-standard boiler tubes to custom technical drawings allows us to provide customized solutions that perfectly meet our customers’ specifications.

- Applications in industry

Our boiler tubes are designed to serve a wide range of industries including oil and gas, power plant, fertilizer, petrochemical, metallurgy and shipbuilding. Our versatility and industry expertise make us a trusted partner for all your pipe needs.

See in detail the types of boiler tubes and their advantages

Fire boiler pipes

Fire boilers are one of the oldest and simplest boiler designs. In these boilers, the hot gases produced in the combustion process pass through tubes surrounded by water. The heat of the gases is transferred through the pipe walls to the water, which is then converted into steam.

Advantages of boiler tubes

- Simplicity : The design of fire tube boilers is simple, which makes them easy to use and maintain.

- Cost-effective : Due to their simple design, fire tube boilers are generally cheaper to manufacture and install.

- Compact design : Fire boilers have a relatively compact design, so they fit into small spaces.

- Ease of maintenance : Boilers are easier to maintain due to their simple design and fewer components.

Water pipe boiler pipes

Water tube boilers are designed to withstand higher pressure and temperatures compared to fire tube boilers. In these boilers, water flows through pipes and external combustion gases heat the water, turning it into steam.

Advantages of water tube boiler tubes

- Higher efficiency : Water tube boilers have better heat transfer capability, resulting in higher efficiency.

- Handling higher pressure and temperature : These boilers can withstand higher pressure and temperature, making them suitable for high demand applications.

- Scalability : Water tube boilers can be easily scaled up to meet higher steam requirements.

- Safety : Due to their design, water tube boilers are generally safer as they are less explosive.

Boiler tube considerations

The material used in the production of boiler tubes plays a crucial role in their performance and durability. Elite Piping Manufacture Co., Ltd. we use a variety of high-quality materials to ensure that our boiler tubes meet the strict requirements of various industries.

Carbon steel

Carbon steel is widely used for boiler tubes because it is strong and can withstand high temperatures. It is cost-effective and provides good thermal conductivity.

Alloy steel

Alloy steel boiler tubes are designed for use in conditions of higher pressure and temperature. The addition of alloying elements improves their strength, durability and resistance to corrosion and oxidation.

Special alloy

Special alloy boiler tubes are used in applications where extreme conditions prevail. These materials provide excellent resistance to high temperatures, corrosion and wear.

Stainless steel

Stainless steel boiler tubes are known for their excellent corrosion resistance, making them suitable for use in corrosive environments. They also offer good thermal conductivity and durability.

Duplex and Super Duplex

Duplex and super duplex stainless steel boiler tubes provide excellent strength and corrosion resistance. They are used in highly corrosive environments such as offshore oil and gas platforms.

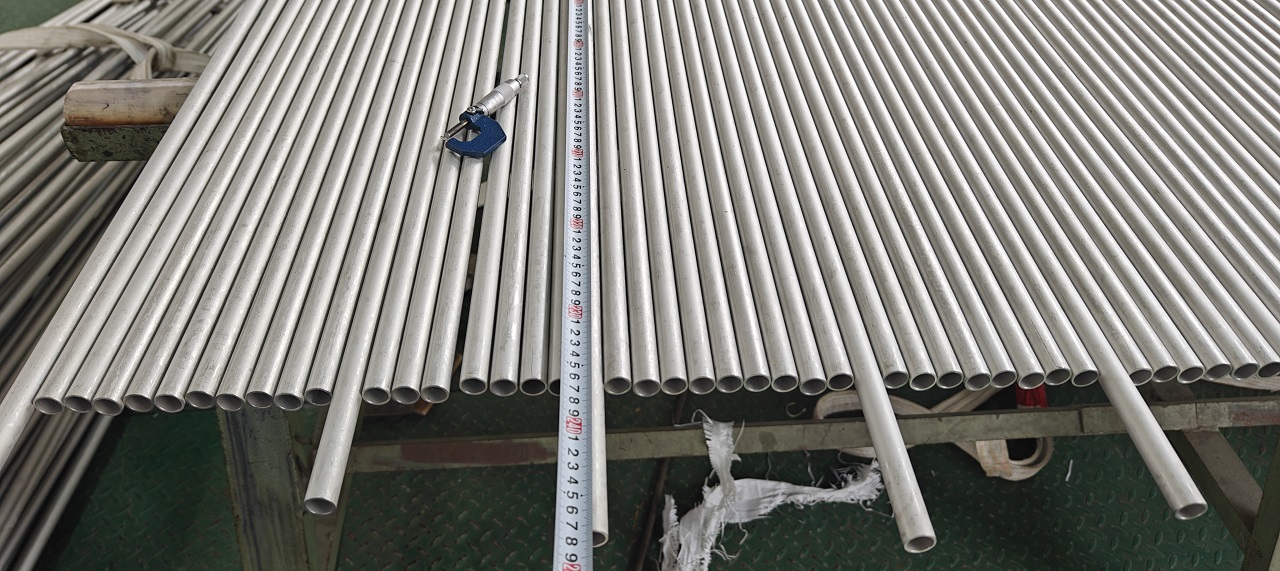

Boiler tube manufacturing process

At Elite Piping Manufacture Co., Ltd, we follow a precise manufacturing process to ensure the highest quality boiler tubes. Here is an overview of our production process:

- Selection of materials

To begin with, we select the best raw materials that meet the required specifications of the desired type of boiler tube.

- Cutting and shaping

The selected materials are cut and molded to the desired shape and size using modern techniques. This step is very important to ensure accurate pipe dimensions.

- Thermal treatment

The formed tubes are heat treated to improve their mechanical properties such as strength, hardness and flexibility. This step is very important to ensure that the pipes can withstand high pressure and temperature.

- Welding and joining

If necessary, the pipes are welded or joined using advanced welding methods. This ensures a strong and smooth connection, improving the overall integrity of the pipes.

- Surface treatment

To improve the appearance and corrosion resistance of pipes, they are treated with surface treatment, such as polishing. This step is important to ensure the tubes perform well in harsh conditions.

- Quality control

Strict quality control measures are applied throughout the production process. Each pipe is inspected and tested to ensure it meets the required standards and specifications.

- Packaging and Delivery

The pipes of the finished boiler are packed carefully so as not to be damaged during transportation. They are then delivered quickly and efficiently to our customers.

Quality assurance and testing

At Elite Piping Manufacture Co., Ltd, quality assurance is a top priority. We have a dedicated quality control team that conducts thorough inspections and testing at every stage of the manufacturing process. Our quality assurance measures include:

- Testing of materials

We carry out material testing to ensure that the raw material meets the required specifications. This includes chemical composition analysis, mechanical property testing and metallurgical testing.

- Dimensional control

The dimensions are checked to ensure that the pipes meet the exact dimensions and required tolerances. This ensures proper fit and performance in intended applications.

- Non-Destructive Testing (NDT)

Non-destructive testing methods such as ultrasonic testing and radiographic inspection are used to detect internal defects or imperfections in pipes. This helps to ensure the structural integrity and reliability of the pipes.

- Pressure test

A pressure test is performed to verify that the pipes can withstand a specified pressure without leaking or failing. This is very important to ensure the performance of the pipes under service conditions.

- Surface inspection

Surface inspection is performed to check for surface defects such as cracks, pits or corrosion. This ensures a smooth and defect-free surface for the pipes.

Global reach and customer satisfaction

Elite Piping Manufacture Co., Ltd has established a strong global presence by exporting our quality boiler tubes to more than 25 countries worldwide. Our commitment to customer satisfaction has earned us a reputation as a reliable and trustworthy pipe supplier in China.

We understand the diverse needs of our international customers and strive to provide customized solutions that meet their specific requirements. Our dedicated customer support team is always ready to help with any question, ensuring a smooth and satisfying experience from start to finish.

Conclusion

Boiler tubes are essential components in many industrial applications, and choosing the right supplier is critical to reliable performance and efficiency. As a leading pipe manufacturer in China, Elite Piping Manufacture Co., Ltd provides high-quality boiler pipes that meet international standards and provide excellent performance in demanding environments.

Our advanced manufacturing capabilities, skilled workforce, comprehensive material knowledge and commitment to quality make us the preferred choice for boiler tubes. Whether you need fire tube boiler tubes, water tube boiler tubes or custom solutions, we have the knowledge and resources to meet your needs.

Cooperate with Elite Piping Manufacture Co., Ltd. and enjoy the benefits of working with a reliable pipe supplier in China . Contact us today to learn more about our products and services and how we can help meet your boiler tube requirements.

Let us help you find the best quality seamless tubes. Elite Piping Co., Ltd offers a wide range of products for the boiler industry. From high-quality seamless tubes to hydraulic tubes and from finned tubes to mechanical tubes, we have a huge range of products. To know more you can call us at +86-18618291381 or send your queries to elite@elitepiping.com.