Share this

In modern industrial fluid systems, the flange strainer plays a vital role. It is a pipeline-mounted filtering device used to remove solid impurities from fluids, protecting equipment and ensuring smooth, safe operations. Whether in oil and gas, chemical processing, power generation, pharmaceuticals, or water treatment, flange strainers are indispensable components.

What Is a Flange Strainer?

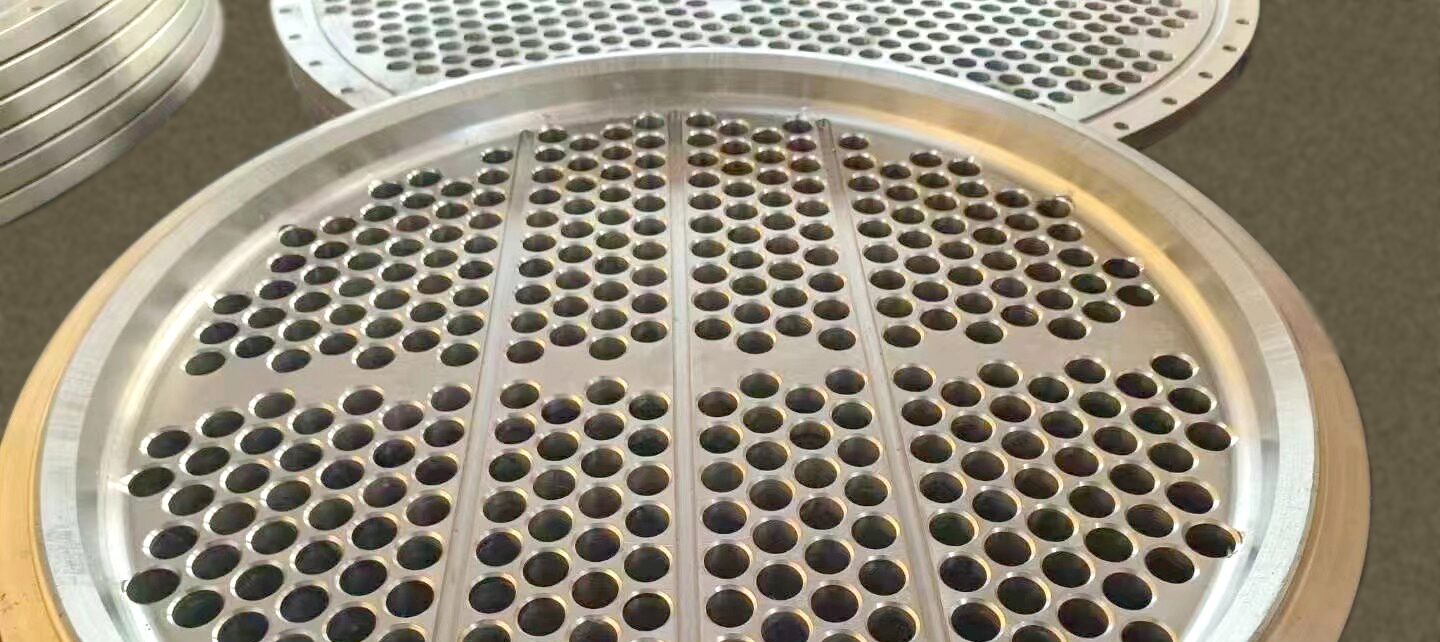

A flange strainer is a type of filter with flanged ends, typically installed at the inlet of a pipeline or upstream of key equipment. It captures solid particles, sand, rust, and other debris in the fluid. Known for its robust construction and easy disassembly, it is suitable for high-pressure and high-temperature environments.

Based on structural design, flange strainers are mainly divided into two types:

Y Strainer: Featuring a Y-shaped filter element, this type is compact and can be installed horizontally or vertically. It is ideal for steam, gas, or liquid systems.

Basket Strainer: Designed with a larger filter area, it is suitable for systems with higher flow rates and commonly used for coarse filtration of liquid media.

Why Choose Flanged Connections?

Compared to threaded or welded connections, flanged connections offer superior sealing performance and mechanical strength. They are also easier to install and dismantle, especially in high-pressure or large-diameter piping systems.

Key Advantages of Flange Strainers:

Efficient Filtration: Effectively removes impurities in fluids, preventing clogging or wear in pumps, valves, and other equipment.

Easy Maintenance: Flanged ends allow quick disassembly of the cover for cleaning or filter replacement.

Durable Construction: Made from high-quality carbon steel, stainless steel, or alloys, suitable for harsh conditions involving pressure, temperature, and corrosion.

Wide Application: Suitable for water, oil, steam, gas, and other media in industries such as oil & gas, chemicals, and power generation.

Application Example:

At a petrochemical plant, a high-pressure pipeline system frequently suffered equipment damage due to debris entering pumps. By installing flange strainers, the system was able to filter out metal particles and sand, significantly reducing pump wear, extending equipment life, and minimizing unplanned downtime.

Selection Tips:

When selecting a flange strainer, consider the following factors:

Type of medium (e.g., water, oil, steam)

Flow rate requirements

Operating pressure and temperature

Required filtration accuracy

Available installation space and ease of maintenance

It is also crucial to choose a reputable manufacturer whose products comply with international standards, such as ASME, DIN, or GB.

Cleaner Fluids. Longer Equipment Life. Safer Systems. — Choose Flange Strainers to Guard Your Process Flow!