Share this

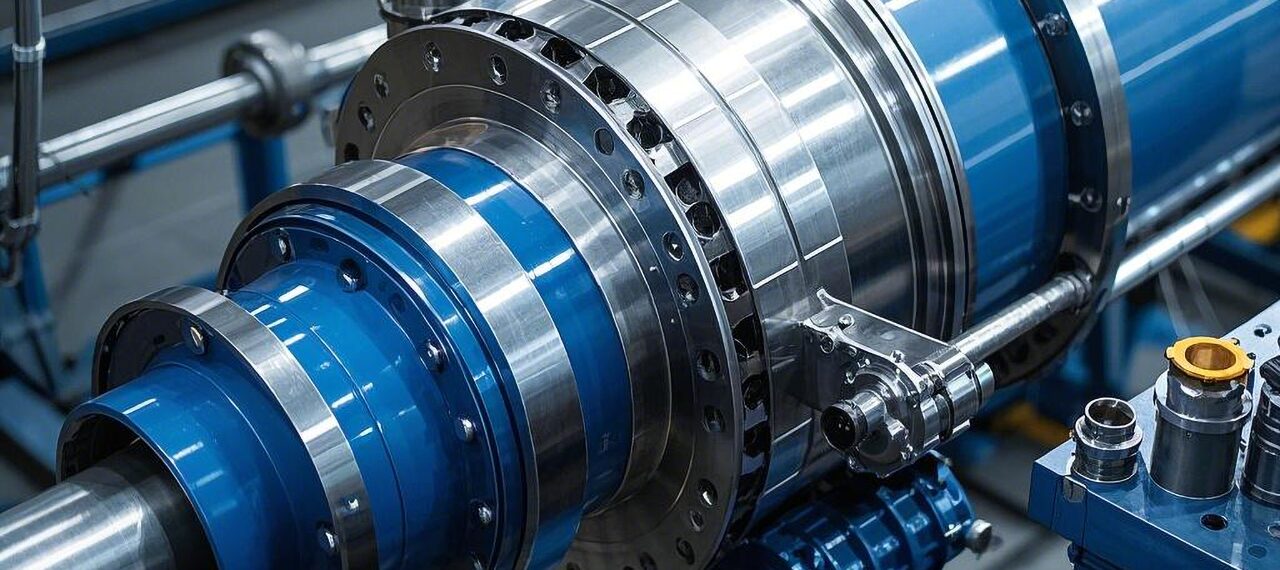

Traditional application fields of flanges include high – tech, offshore engineering, chemical industry, clean energy and other fields. The following is a detailed introduction:

High – tech Field

- Aerospace: In the fuel systems, hydraulic systems and various pipeline connections of aircraft, high – precision and high – strength flanges are required to ensure the tightness and reliability of the systems, so as to adapt to complex flight environments such as high altitude, high pressure and high speed. For example, the fuel delivery pipeline connections of aircraft engines adopt flanges manufactured with special materials and processes. In the aerospace field, the propellant delivery pipelines of rockets and various pipeline systems of satellites also rely on the application of flanges, which need to withstand the huge pressure and vibration during the launch process.

- Electronics and Semiconductors: In the production equipment of electronics and semiconductors, flanges are needed to connect the pipeline systems for transporting various special gases and chemical reagents. These flanges usually have extremely high cleanliness requirements to prevent impurities from contaminating the semiconductor production process. For example, in the photolithography process of chip manufacturing, the flanges for connecting the pipelines transporting photoresist and other chemical reagents need to have high – precision processing technology and good corrosion resistance to ensure the stability and accuracy of reagent delivery.

Offshore Engineering Field

- Offshore Drilling Platforms: A large number of flanges are required to connect pipelines and equipment on offshore drilling platforms, such as oil and gas transportation pipelines, seawater treatment systems, and drilling fluid circulation systems. Due to the harsh offshore environment, these flanges need to have good corrosion resistance, high strength and fatigue resistance to withstand the erosion of seawater, the impact of waves and long – term vibration.

- Marine Survey Equipment: In marine monitoring, scientific research and other activities, the flanges used to connect the pipelines and cables of marine survey equipment need to adapt to different water depths, water pressures and seawater temperatures to ensure the stable operation of the survey equipment and the reliability of data transmission.

Chemical Industry Field

- Chemical Production Plants: In the production processes of various chemical products, such as oil refining, acid – base production, and fertilizer manufacturing, there are a large number of high – temperature, high – pressure and highly corrosive media transportation and reactions. Flanges are widely used to connect equipment such as reaction kettles, towers, heat exchangers, pumps, valves and pipelines, ensuring the tightness and safety of the entire production system.

- Chemical Storage Equipment: For equipment such as storage tanks and tank trucks used to store chemical raw materials, intermediate products and finished products, the connection between the inlet and outlet pipelines and the tank body usually also adopts flange connection. This facilitates the installation, maintenance and repair of the equipment, and at the same time ensures the tightness during the storage process to prevent chemical leakage.

Clean Energy Field

- Wind Power Generation: The towers of wind turbines are usually composed of multiple sections, and the connection between each section of the tower is through flanges, enabling the tower to form a stable whole to support the weight of the wind turbine and withstand the action of wind force. In addition, in the nacelle of the wind turbine, flanges are also used to connect various pipelines and equipment.

- Solar Power Generation: In solar thermal power generation systems, flanges are required to connect the pipeline systems for transporting heat – transfer oil, steam and other media. In solar photovoltaic power generation systems, although the application of flanges is relatively less, flanges may also be used in the connection of support structures and cable trays in some large – scale photovoltaic power plants.