Share this

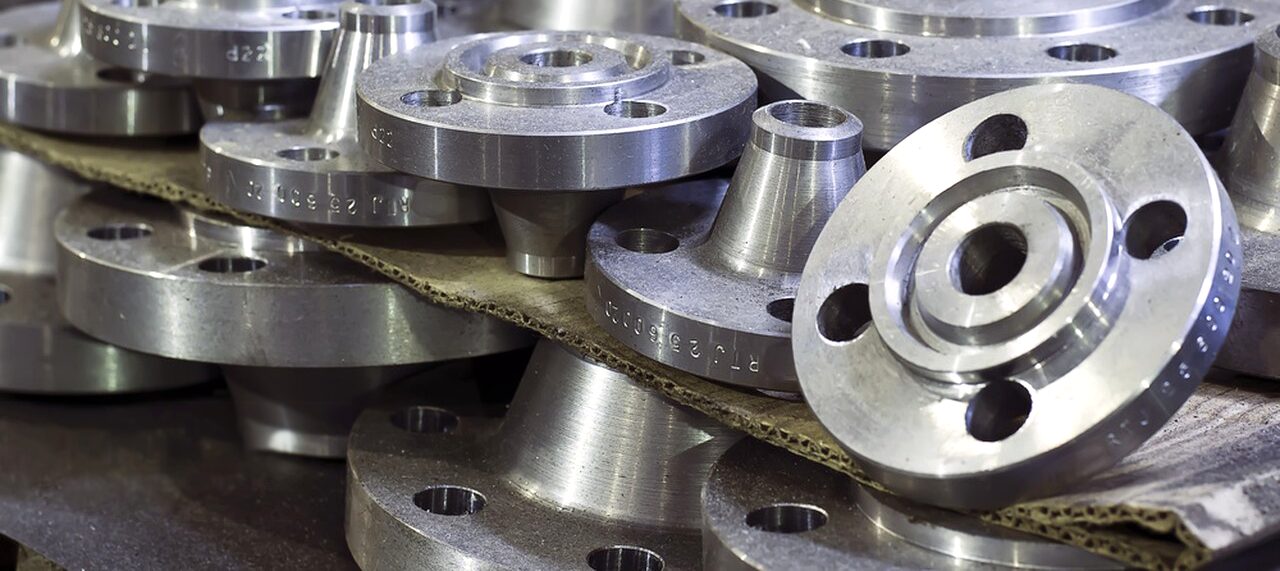

Welcome to Elite Flange, a leader in high-quality piping solutions. Our extensive range of flanges is designed to meet the diverse needs of various industries, ensuring strength, durability, and exceptional performance. In this article, we’ll dive into the five main types of flanges we proudly manufacture: Weld Neck Flange, Long Weld Flange, Blind Flange, Socket Weld Flange, and Threaded Flange. Each type comes with distinct features and benefits tailored to optimize your piping systems.

1. The Weld Neck Flange: A Staple for High-Pressure Systems

First on our list is the Weld Neck Flange, renowned for its robustness and reliability in critical applications. The distinguishing feature of this flange is its long, tapered hub that facilitates smooth stress distribution along the pipe, making it ideal for high-pressure and high-temperature environments.

Benefits of Weld Neck Flanges:

- Optimal Stress Distribution: The design of the tapered hub reduces the concentration of stress, which is particularly beneficial in systems handling severe conditions.

- Seamless Flow: The flange is welded directly to the pipe, creating a seamless connection that minimizes turbulence and promotes stable fluid flow.

- High Durability: Fabricated from high-quality materials, these flanges ensure longevity even under demanding conditions.

Weld neck flanges are frequently used in industries such as oil and gas, petrochemicals, and power generation where safety and reliability are paramount.

2. The Long Weld Flange: Extending the Utility

The Long Weld Flange is similar to the standard weld neck flange but with an extended hub. This feature allows for additional spacing between the pipe and connected components, providing greater versatility in specific applications.

Why Choose Long Weld Flanges?

- Extended Hub for Flexibility: The extra length makes these flanges suitable for use in setups where spacing is crucial.

- Enhanced Strength: The longer hub provides an extra measure of strength and stability, which is vital for certain high-stress environments.

- Consistent Flow: Just like the standard weld neck flange, the long weld flange ensures a smooth transition between the pipe and flange, promoting uninterrupted flow.

Long weld flanges are particularly useful in industries that require precision spacing and alignment between pipes and other equipment, such as refineries and chemical processing plants.

3. The Blind Flange: Sealing with Confidence

The Blind Flange stands out as the most distinctive type in our range, primarily due to its lack of a bore. This solid design makes it indispensable for closing off piping systems and pressure vessel openings.

Key Advantages of Blind Flanges:

- Leak Prevention: The robust, sealed design ensures a tight, secure closure that effectively prevents leaks.

- Inspection and Testing: Blind flanges facilitate pressure testing and inspections without permanent alterations to the piping system.

- Future Expansion: These flanges can be easily removed or replaced, allowing for seamless system expansions when needed.

Blind flanges are essential components in applications where sections of piping need to be isolated for maintenance, testing, or modification. Their strength and versatility make them a must-have for industries like water treatment, oil and gas, and construction.

4. The Socket Weld Flange: Perfect for Smaller Pipes

The Socket Weld Flange is designed with a recessed area where the pipe is inserted before welding. This creates a clean, strong connection that is ideal for smaller pipe sizes and high-pressure systems.

Benefits of Socket Weld Flanges:

- Enhanced Flow Efficiency: The design helps maintain a smooth bore, which minimizes pressure drops and improves flow characteristics.

- Simplified Installation: The socket weld process is straightforward, making installation quicker compared to other types of welded flanges.

- Reliable Performance: The secure connection is highly reliable, providing the durability needed for high-pressure applications.

Socket weld flanges are often used in industries where pipe cleanliness and pressure control are vital, such as pharmaceutical, food processing, and chemical sectors.

5. The Threaded Flange: Simplicity and Strength Combined

Lastly, we have the Threaded Flange, a practical choice for applications where welding is not feasible. This flange connects directly to pipes with matching male threads, making it especially suited for low-pressure systems.

Why Opt for Threaded Flanges?

- Ease of Installation: Since no welding is required, installation is simpler and faster, which reduces downtime during maintenance or repairs.

- Reusability: Threaded connections can be disassembled and reused, making them economical for temporary or modular piping systems.

- Reliable Sealing: Despite their simpler connection method, threaded flanges provide a strong seal that prevents leakage effectively.

Threaded flanges are commonly used in plumbing, water treatment facilities, and systems that need frequent reconfiguration or disassembly.

Elite Flange: Unmatched Quality and Craftsmanship

At Elite Flange, we are committed to manufacturing flanges that meet the stringent requirements of your most demanding projects. Our flanges are crafted from the highest quality materials, ensuring they withstand harsh conditions and provide consistent performance.

Why Choose Elite Flange for Your Piping Solutions?

- Comprehensive Range: We offer a wide array of flanges, from weld necks and long welds to specialized types like blinds and sockets.

- Superior Quality: Every flange we produce meets or exceeds industry standards for safety and performance.

- Customer-Centric Approach: We prioritize customer satisfaction and work closely with clients to provide customized solutions tailored to their unique needs.

The Importance of High-Quality Flanges in Your Projects

Choosing the right type of flange is essential for the efficiency and safety of your piping system. High-quality flanges ensure:

- Secure Connections: Prevent leaks and enhance the overall safety of the system.

- Improved System Longevity: Durable flanges help extend the life of your piping setup.

- Reduced Maintenance Costs: Reliable components minimize the need for frequent repairs, saving time and money.

Application Areas of Elite Flange Products

Our flanges are trusted by clients across various industries, including:

- Oil and Gas: High-pressure and corrosive environments demand flanges that can withstand extreme conditions, making our weld neck and blind flanges a top choice.

- Chemical Processing: Our socket weld and threaded flanges offer the perfect solution for precise fluid handling and pressure regulation.

- Power Generation: The strength and durability of our long weld flanges ensure optimal performance in power plant applications.

Contact Us Today

Ready to upgrade your piping solutions? Elite Flange is here to provide you with top-of-the-line products tailored to your project’s needs. Contact us today, and let’s start working together to build systems that last. Your satisfaction is our commitment, and we look forward to becoming your trusted partner in piping excellence.