Share this

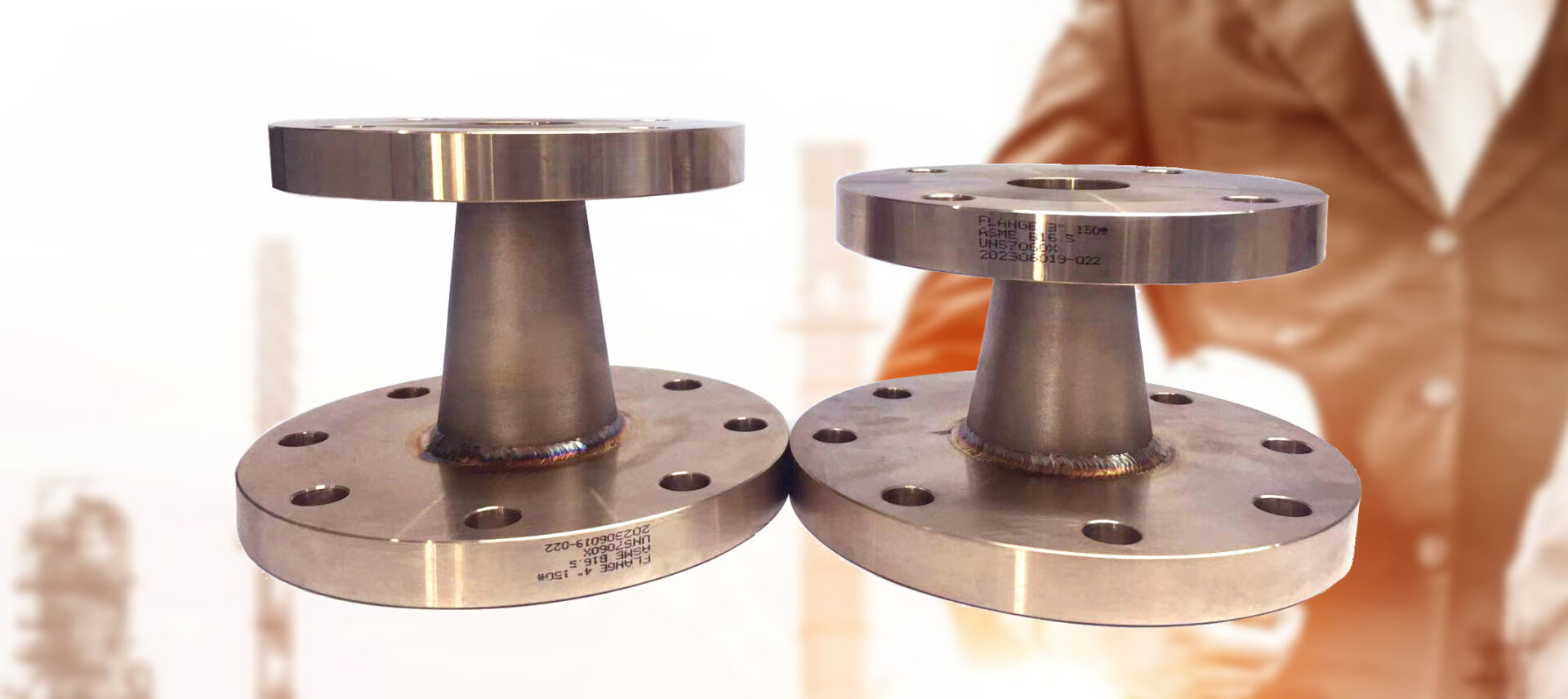

Copper-nickel flanges have the following characteristics:

1. Strong Corrosion Resistance: Copper-nickel alloys exhibit excellent resistance to corrosion, especially in seawater, acidic, and alkaline environments. This makes copper-nickel flanges suitable for applications in marine engineering, chemical industries, petroleum, and fertilizers.

2. High-Temperature Stability: Copper-nickel alloys generally possess good high-temperature stability, allowing them to maintain their mechanical properties and corrosion resistance in relatively high-temperature working environments.

3. Good Conductivity: Copper-nickel alloys demonstrate good electrical conductivity, making them suitable for applications requiring electrical conductivity, such as power transmission and electronic devices.

4. Weldability: Copper-nickel alloys typically have good weldability, enabling copper-nickel flanges to be securely and tightly connected to other pipes or equipment through welding or other similar methods.

5. Stable Mechanical Properties: Copper-nickel alloys usually have favorable mechanical properties like strength, toughness, and hardness, contributing to the stability and durability of flange connections.

6. Ease of Processing: Copper-nickel alloys are relatively easy to process and shape, facilitating the manufacturing of flange products tailored to specific requirements.

7. Wear Resistance: Copper-nickel alloys exhibit good wear resistance, making them suitable for use in pipe systems where there is substantial fluid or gas flow and high flow velocities.

It is important to note that different copper-nickel alloy materials may possess varying characteristics. Therefore, when selecting and applying copper-nickel flanges, it is essential to consider both specific engineering requirements and material properties. Additionally, proper installation and maintenance are crucial to ensure connection quality and safety.