Share this

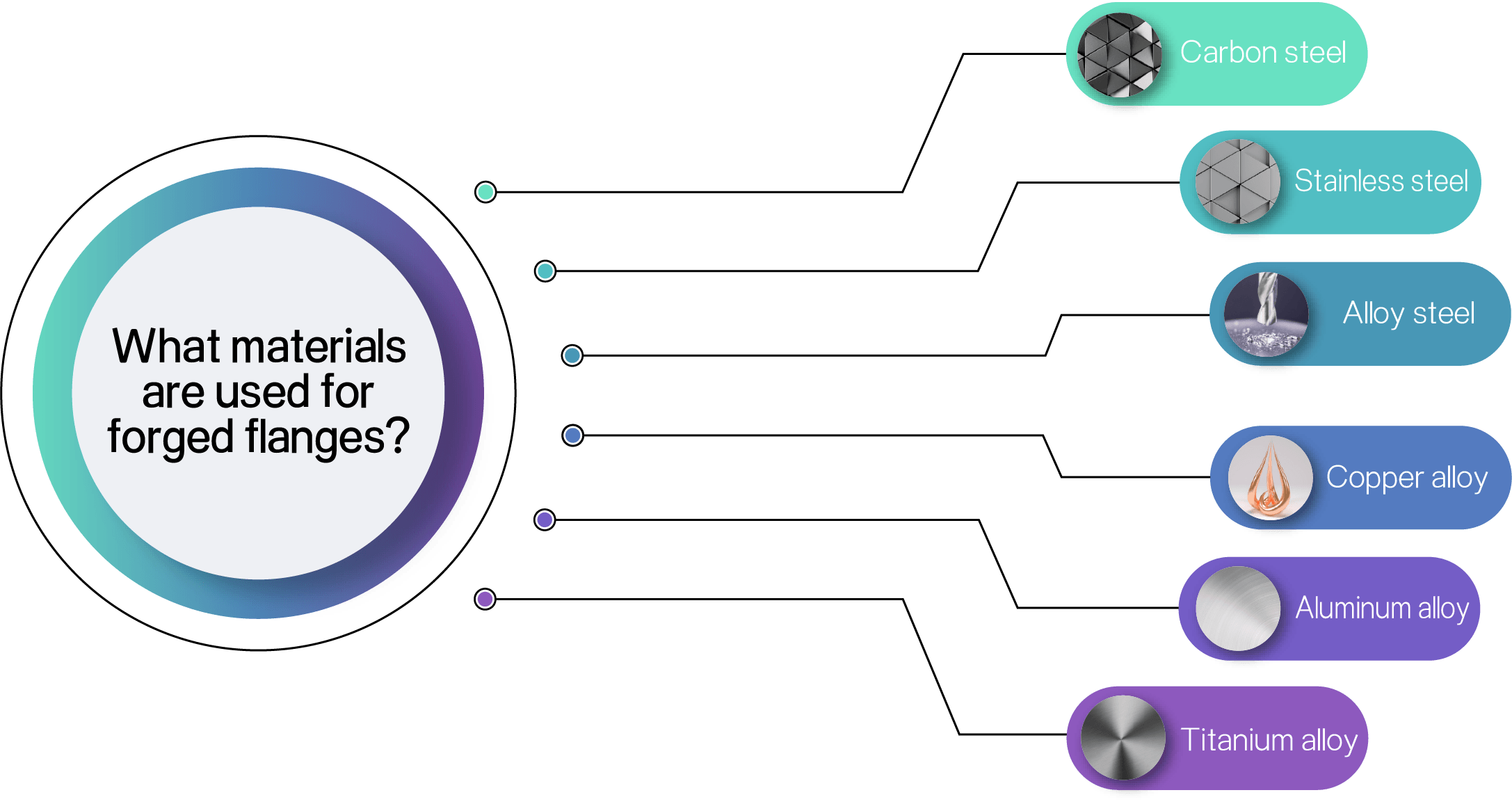

Forged flanges are widely used in various industries and fields, and different materials need to be selected to meet different requirements in different application scenarios. Here are some commonly used materials for forged flanges:

Carbon steel: Forged carbon steel flanges have high strength and hardness and are widely used for pipeline systems and equipment connections in petrochemical, electric power, shipbuilding, and other industries.

Stainless steel: Forged stainless steel flanges have good corrosion resistance and high-temperature strength, suitable for pipeline systems and equipment connections in the food, pharmaceutical, marine, and other industries.

Alloy steel: Forged alloy steel flanges have higher strength, hardness, and corrosion resistance and are widely used in pipeline systems and equipment connections under high temperature and high-pressure conditions.

Copper alloy: Forged copper alloy flanges have good thermal conductivity and corrosion resistance and are suitable for pipeline connections in cooling water pipelines, chemical treatment equipment, and other occasions.

Aluminum alloy: Forged aluminum alloy flanges have good strength and corrosion resistance and are suitable for pipeline systems and equipment connections in aviation, automotive, and other industries.

Titanium alloy: Forged titanium alloy flanges have extremely high strength and corrosion resistance and are widely used in high-demand applications in industries such as aerospace, aviation, and medical.

The appropriate material should be selected based on specific usage conditions and requirements to ensure the connection quality and safety performance of forged flanges.

For pipe fittings, please link: https://bekingpiping.com