What is the process of making flanges?

Flanges are a common type of mechanical joint used to connect pipes, valves, pumps, and other equipment. Here is the process for making flanges:

Material preparation: Select materials suitable for making flanges, such as carbon steel, stainless steel, and alloy steel.

Make the blank: Process the selected material into a round blank.

Cutting: Cut the round blank to the required size, usually using machine tools.

Drilling: Drill holes in the blank for installing bolts and securing the flange.

Processing: Put the blank into the processing equipment to create the required grooves and raised faces so that the flange can connect with other equipment.

Surface treatment: Apply surface treatment to the processed flange to prevent rust and corrosion.

Inspection: Inspect the flange’s dimensions, hole spacing, aperture, thread, and other factors to ensure they meet the requirements.

Marking: Mark the approved flanges to facilitate their use during installation.

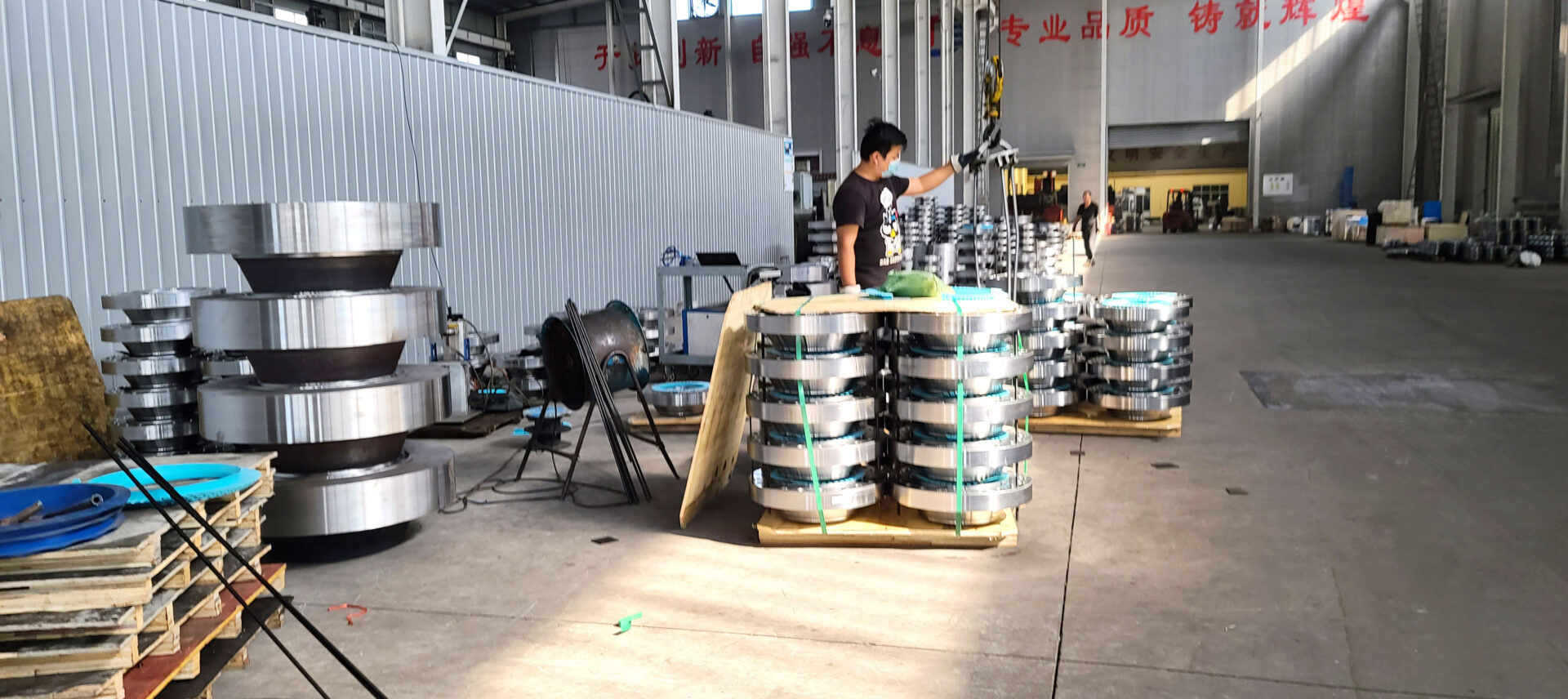

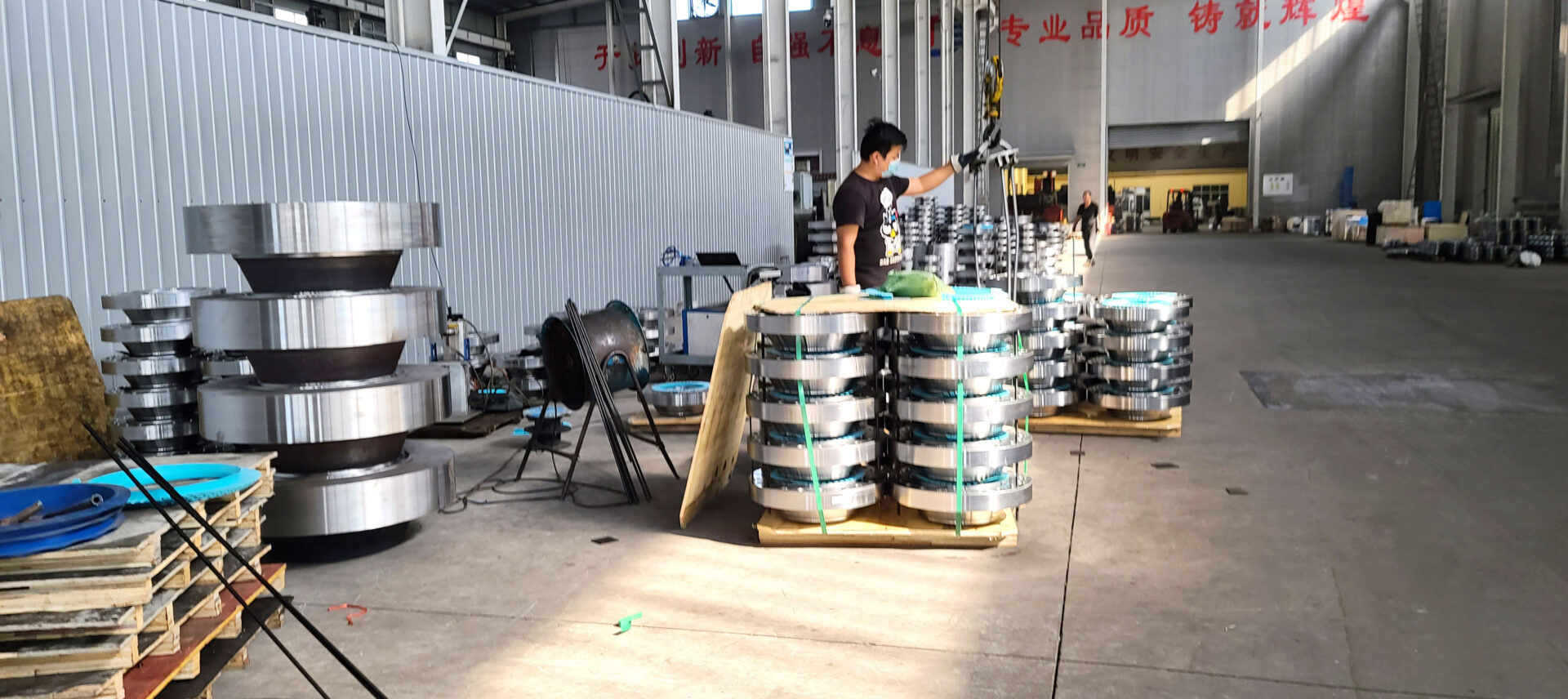

Packaging: Package the flanges, usually using wooden boxes or plastic bags to ensure that they do not get damaged during transportation and storage.

The above is the process for making flanges, and different types of flanges may have some differences in the manufacturing process.