Share this

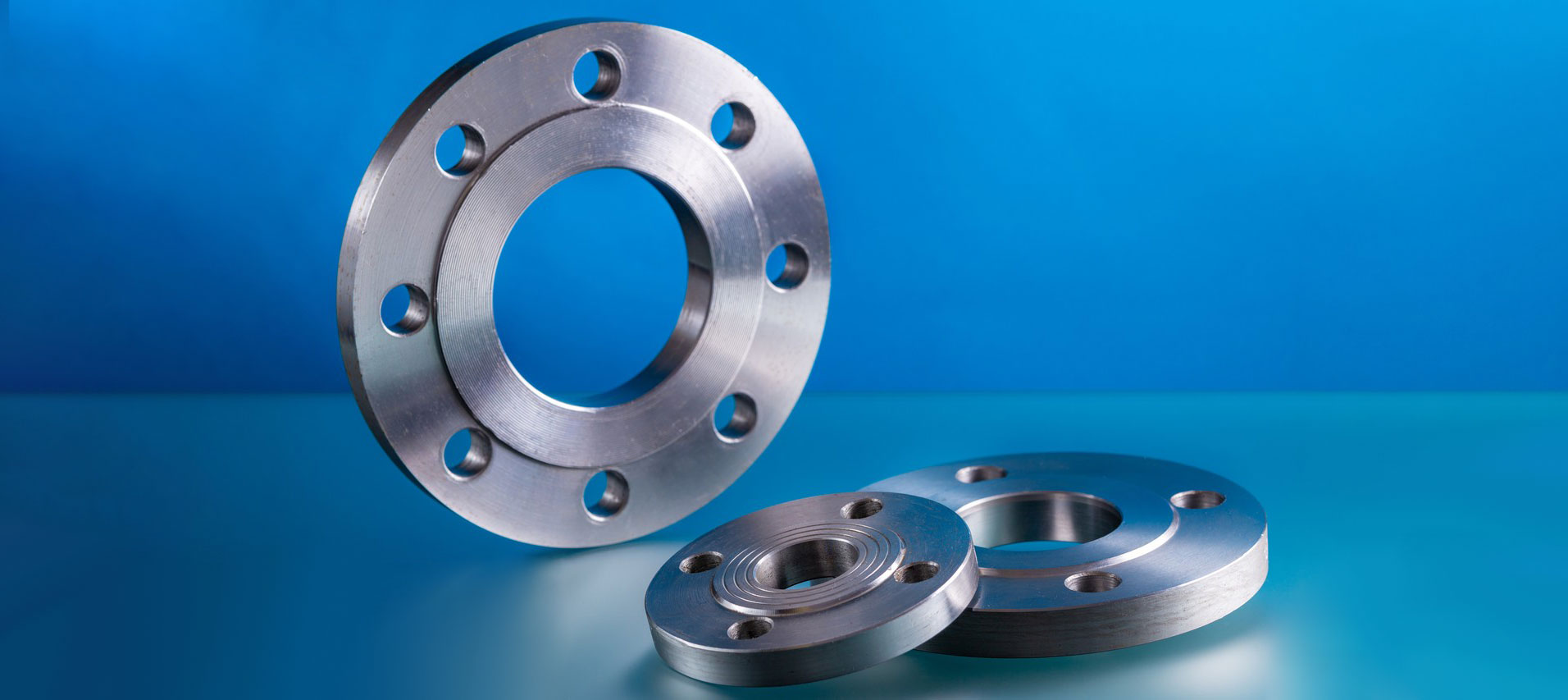

The American standard or flange is the part that connects the pipe to the pipe to each other and is attached to the pipe end. There are holes in the American standard flange, the bolts make the two flanges tightly connected, and the flanges are sealed with gaskets. American standard flanges can be cast or threaded or welded.

Each American standard flange pipe material grade specifies the specifications and corresponding materials of the pipe materials (pipes, fittings, valves, flanges, fasteners, etc.) used in detail.

Made a systematic introduction to the standards of pipes, pipe fittings, flanges and fasteners, valves, etc., and then introduced the relevant standard system of American Standard around the customization work of the pipe material grade regulations of the American Standard system, and hoped that the formulation of the American Standard pipe material grade The work draws lessons.

The American standard flange pipe material grade is based on a certain application standard system, and grades the pipes in the project according to the design temperature, design pressure and transmission medium requirements of the pipes.

American Standard or flange measurement method:

1. First, measure the dimensions of the American Standard or flange outer diameters D1 and D2 accurately. If the measured data is 157.5mm, then the dimension is 157.5mm.

2. Measure the dimension b of the American standard or flange gap, and measure four points (evenly distributed) on the circumference.

3. Measure the enlarged part of the depth C (the size between the American standard or the outer edge of the flange and the bolt (composition: head and screw)) and measure the size of C at the 1234 position of the American standard flange, and select smaller size.

The butt welding flange is a kind of pipe fitting, which refers to a flange with a neck and a round pipe transition, which is connected to the pipe by butt welding. It is not easy to deform, has good sealing, and is widely used. It is suitable for pipelines with large fluctuations in pressure or temperature or high-temperature, high-pressure and low-temperature pipelines. The advantage is that the price is relatively cheap, and the nominal pressure does not exceed 2.5MPa;

On the pipeline of the flammable and explosive medium, the nominal pressure is about PN16MPa.

What are the basic process steps of American standard flange-free forging

4. Measure the different dimensions of the two American standard flanges, and choose the size where the gap between the two American standard flanges is very large.

5. Finally, fill in the measured data in the table.

American Standard or lug seal form

Or the two sealing surfaces of the flange bolt (composition: head and screw) squeeze the flange gasket against each other to form a seal, but this also causes damage to the seal. In order to maintain the seal, a huge bolt force has to be maintained.

For this reason, the bolt will be bigger. And larger bolts will match larger nuts, which means that bolts with larger diameters are required to create conditions for tightening the nuts. As everyone knows, the larger the diameter of the bolt, the applicable flange will become curved.

A good way is to increase the wall thickness of the flange part. The whole installation would require a lot of sizes and weights, which is a particular problem in the offshore environment, where weight is always the main concern that one has to pay attention to. And, fundamentally speaking, the ANSI flange is an ineffective seal, which requires 50% of the bolt load to squeeze the gasket, while only 50% of the load is used to maintain the pressure.

The main bad design of the ANSI flange is that it cannot be guaranteed to be leak-free. This is the shortcoming of its design: the connection is dynamic, and cyclic loads such as thermal expansion and fluctuations will cause movement between the flange faces, affecting the function of the flange, thereby compromising the integrity of the flange, and eventually causing a leak.

What are the basic process steps of American standard flange-free forging

The basic process of American standard flange-free forging: during free forging, the shape of the forging is gradually forged from the blank through some basic deformation processes. The basic processes of free forging include upsetting, drawing, punching, bending and cutting (cutting; truncating).

1. Upsetting Upsetting is the operation process of forging the original billet in the axial direction to reduce its height and increase its cross-section. This process is often used for forging gear blanks and other disc-shaped forgings. Upsetting is divided into two types: total upsetting and partial forging.

2. Elongation Elongation is a forging process that increases the length of the blank and reduces the cross-section. It is usually used to produce shaft blanks, such as lathe spindles and connecting rods. The flat welding flange is a flange that is directly welded to the equipment or pipeline through the fillet weld.

The structure is simple and the processing is convenient. Its stress characteristics are between the integral flange and the loop flange. The flat welding flange is divided into plate flat welding flange and neck flat welding.

The flat welding flange is low in cost and short in the production cycle. It is more commonly used. A flange type is widely used in various fluid pipelines.

3. Punching is a forging process in which a punch is used to punch out a through hole or a non-through hole on the blank.

4. Folding is a forging process that bends the blank into a certain angle or shape.

5. Twisting is a forging process in which one part of the blank is rotated at a certain angle relative to the other part.

6. The forging process of dividing the blank or cutting the head. The flat welding flange is a flange that is directly welded to the equipment or pipeline through the fillet weld. The structure is simple and the processing is convenient. Its stress characteristics are between the integral flange and the loop flange.

The flat welding flange is divided into plate flat welding flange and neck flat welding. The flat welding flange is low in cost and short in the production cycle. It is more commonly used. A flange type is widely used in various fluid pipelines.

Application of American Standard or Flange Dislocation Centralizer

Regarding the development of the American Standard Flange Displacement Centralizer, experts have already begun to research and produce such a thing – the American Standard Flange Displacement Centralizer.

In the process of oil field production and construction, crowbars, reversing chains, loosening flange bolts, and even electric welding are often used to reset the seriously misaligned parts of pipelines and flanges.

These methods are unsafe and difficult to reset and correct. And installation quality is not up to standard and other issues. For this reason, the American Standard flange misalignment centralizer was developed.

The American standard flange misalignment centralizer uses the low point of the flange misalignment as the fulcrum, the two claws hang on the two holes of the appropriate flange, rotate the positioning screw to position, and then rotate the other end of the screw to make the flange misalignment holes completely aligned.

The centralizer is used to test the filter flanges of the pump room of No. 3, 4, 5, 6 and 8 oil production metering transfer stations in the oil production operation area, and two people can complete all procedures from flange dislocation and straightening to screw installation. It is labor-saving and safe, which can reduce maintenance and repair costs and shorten maintenance time.

For pipe fittings, please link: https://bekingpiping.com