Share this

Large thread flange forging dies according to the embodiment of movement can be divided into orbital forging, swing swage forging, roll forging, cross wedge rolling, ring rolling, roll cross rolling and so on. It is fired at high temperature, compact, except for the abrasive deburring process on the inner wall of the tube after which it smooths and cleans the inner wall with good surface flatness without clogging the powder.

The market prices of mainstream steel products have been adjusted slightly. The domestic steel market demand has entered the off-season. Steel traders are not willing to store in winter. Neck flange connection or flange joint refers back to the detachable connection of the flange, Gasket and bolt as a group of the combined sealing structure.

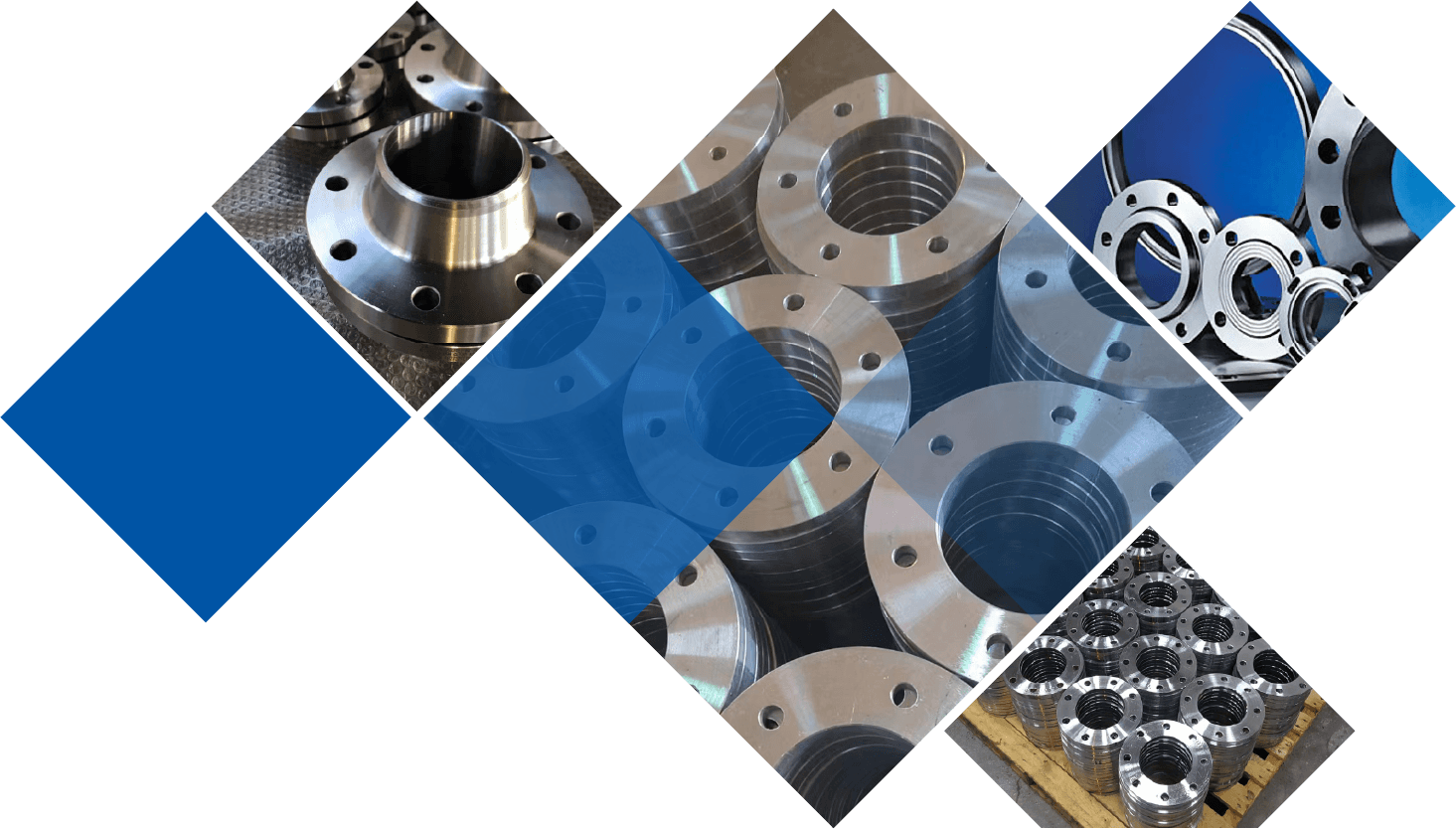

Pipe flange refers back to the flange used for piping in the pipeline installation, And used on the equipment refers to the inlet and outlet flange of the equipment. There are holes in the flange, and the bolts tightly connect the two flanges. With the development of finite element technology, stress calculation is possible, and the real and reliable analysis results of complex structures have also become an important means of engineering analysis, finite element technology to solve flanges, gaskets, and bolted connection systems are more feasible and effective methods.

The traditional method to solve the problem of replacing flange leakage sealing components, replacing or applying sealants and pipe flanges, but this method has serious limitations, and some leakage is a limitation of the requirements of a safe working environment, which cannot be solved on-site. Polymer composites can be used in current site blocking, which is blessed by people in the developed world. The blue system is a very ideal method, especially in the case of explosions, and it shows its unique advantages. Polymer The construction process of composite material technology is simple, safe, and low in cost. It can solve most of the company’s flange leakage problems, eliminate potential safety hazards, and save maintenance and repair costs for enterprises.

The flat welding flange is a flange that is directly welded to the equipment or pipeline through the fillet weld. The structure is simple and the processing is convenient. Its stress characteristics are between the integral flange and the loop flange. The flat welding flange is divided into plate flat welding flange and neck flat welding. The flat welding flange is low in cost and short in the production cycle. It is more commonly used. A flange type is widely used in various fluid pipelines. The neck flange is a part that is connected to each other between the shaft and the shaft, and is used for the connection between the pipe ends; it is also useful for the flange on the inlet and outlet of the equipment and is used for the connection between two equipment, such as the flange of the reducer.

B Weld the short and thick plate cylinder part of the flange outer frequency band split ring, the sealing surface after welding is processed, and the flange ring has a short part connection in the opened stepped groove to ensure the welding quality, so the sealing performance is good, According to Jinggao’s sealing requirements, according to the overall design of the inspection flange. The heating temperature and the metal material are processed with the heat treatment head, but generally, the heating is higher than the phase transition temperature, and the high temperature is used to obtain the structure.

For pipe fittings, please link: https://bekingpiping.com