Share this

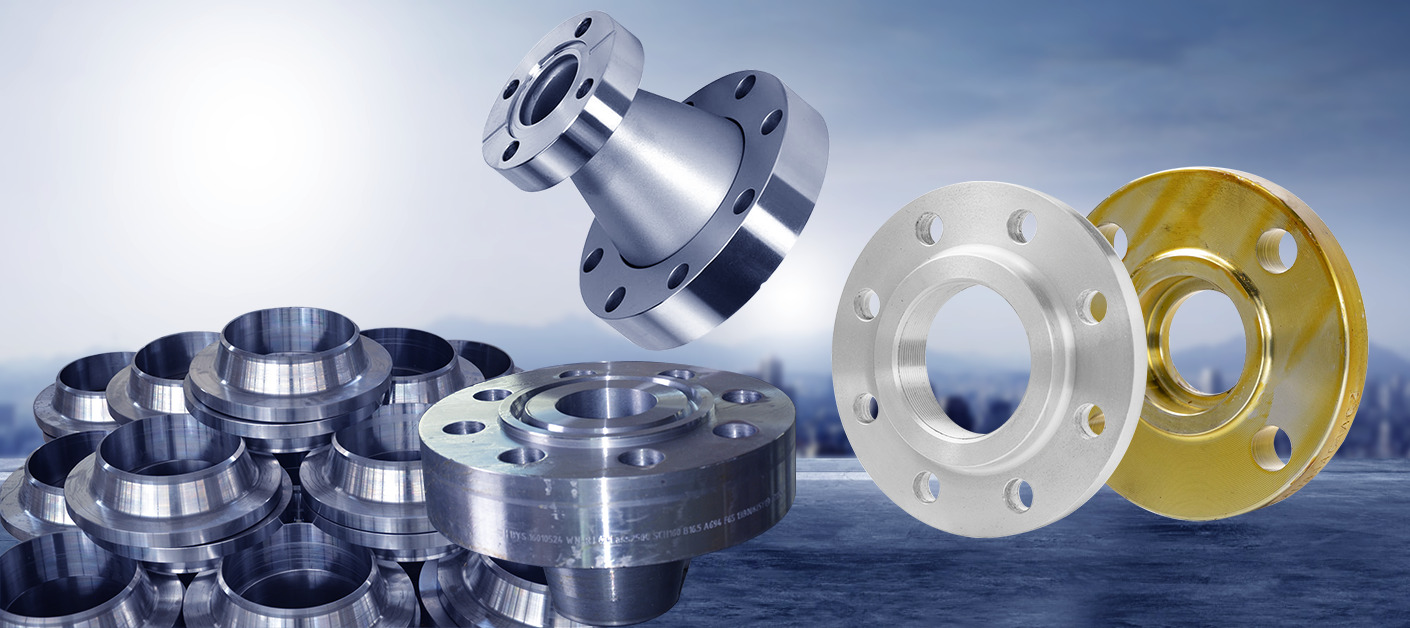

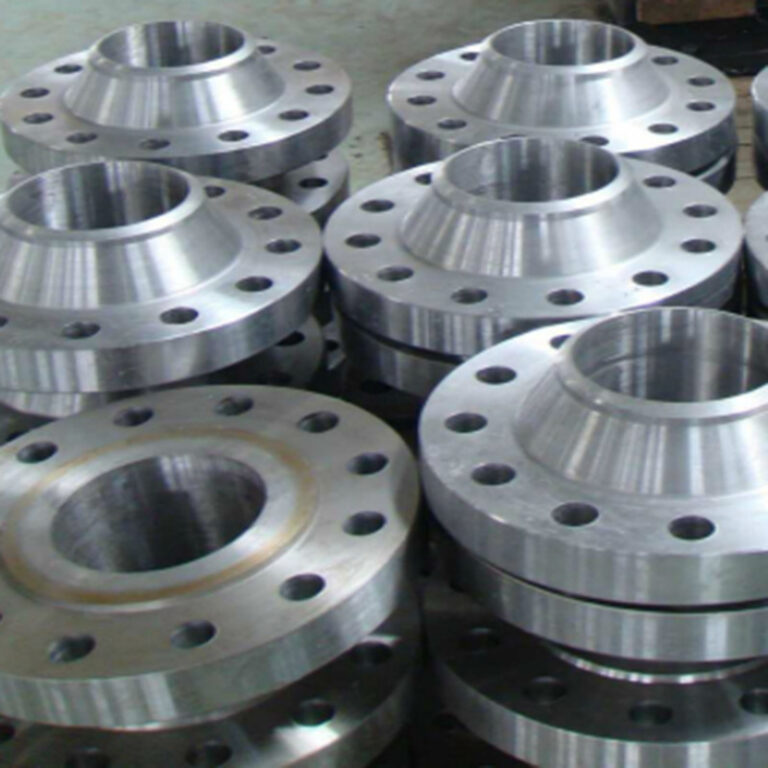

In actual production and development, butt welding flanges are manufactured and produced in different ways, methods and processes. According to the process methods and principles, they have important value and effects in different aspects, and certain elements are added in actual production. Increase the characteristics and value of carbon steel flanges, and show good use characteristics and value of good flanges.

In industrial pipelines, butt welding flange connections are widely used. In the home, the pipe diameter is small, and it is low pressure, and the butt welding flange connection is not visible. If in a boiler room or production site, there are flanged pipes and equipment everywhere

What are the technical requirements for butt welding flanges?

1. The level and technical requirements of butt welding flanges shall meet the corresponding requirements of JB4726-4728. There are two types of flat welding flanges: Slip-On-Welding Plate Flange and Slip-On-Welding Hubbed Flange.

1. Forgings of carbon plain steel and stainless steel (stainless acid-resistant steel) with a nominal pressure PN of 0.25MP-1.0MPa are allowed to use grade I forgings.

2. In addition to the following regulations, forgings with a nominal pressure PN of 1.6MPa-6.3MPa should meet the requirements for forgings of Class II or above. When the flange plate manufacturer pumps and valves, when connecting with the pipeline, the parts of this equipment and equipment are also made into the corresponding flange shape, also known as flange connection.

3. Those who meet one of the following conditions shall meet the requirements of III and forgings:

(1) Forgings for flanges with nominal pressure PN≥10.0MPa;

(2) Chromium-molybdenum (molybdenum) steel forgings with nominal pressure PN>4.0MPa;

(3) Ferrite steel forgings with nominal pressure PN>1.6MPa and working temperature ≤-20 degrees Celsius (°C).

Standard production and processing of butt welding flange welding

2. Butt welding flanges are generally made of forgings or forgings. When made of steel plate or section steel, the following requirements must be met:

1. The butt welding flange should be tested by ultrasonic (a sound wave with a frequency higher than 20,000 Hz) without delamination defects;

2. It should be cut into strips along the rolling direction of the steel, bent and welded into a ring, and the surface of the steel should be formed into a cylindrical surface ring. It is not allowed to use steel plate to directly machine into butt welding flange with neck;

3. The butt weld of the ring should adopt full penetration weld;

4. The butt weld of the ring should be subjected to post-weld heat treatment, and ray or ultrasonic (a sound wave with a frequency higher than 20,000 Hz) should be used for flaw detection, and the radiation flaw detection meets the requirements of Class II of JB4730, and the ultrasonic flaw detection meets the Class I of JB4730. Require.

Standard production and processing of butt welding flange welding

The main functions of butt welding flanges are divided into the following categories:

1. If the pipeline fails, it is easy to disassemble and test.

2. Connect the pipeline and keep the pipeline in good sealing performance;

3. If there is a problem with a certain section of the pipeline (Emerson), it is convenient to replace a certain section of the pipeline;

Butt welding flanges have certain technical requirements and technical parameters in production and use, and are produced and processed according to certain methods and methods:

1. The butt weld of the ring should be subjected to post-weld heat treatment (chǔ lǐ), and ray or ultrasonic (a kind of sound wave with a frequency higher than 20,000 Hz) flaw detection, and the ray flaw detection meets the Class II requirements of JB4730, and the ultrasonic flaw detection meets the requirements of Class II. Class I requirements of JB4730.

Neck flange connection or flange joint refers to a detachable connection in which flanges, gaskets and bolts are connected to each other as a set of combined sealing structures. Pipe flange refers to the flange used for piping in the pipeline installation, and used on equipment refers to the inlet and outlet flanges of the equipment. There are holes in the flanges, and bolts make the two flanges tightly connected.

Standard production and processing of butt welding flange welding

Welding flanges are produced and processed with certain welding standards and technologies, which conform to the corresponding national production standards and requirements.

2. The steel plate for the production of butt welding flanges should be inspected by ultrasonic (a sound wave with a frequency higher than 20,000 Hz), without delamination defects, to ensure good quality and performance problems, and to be produced and inspected according to certain quality requirements to ensure production. And the steel plate used has no quality problems;

3. It should be divided into strips along the rolling direction of the steel, butt-welded into a ring shape by bending, and the surface of the steel should be formed into a cylindrical surface of the ring. In the production of flanges, steel plates shall not be directly machined into flanges with necks, and certain processes shall be used to manufacture and process them.

For pipe fittings, please link: https://bekingpiping.com