Share this

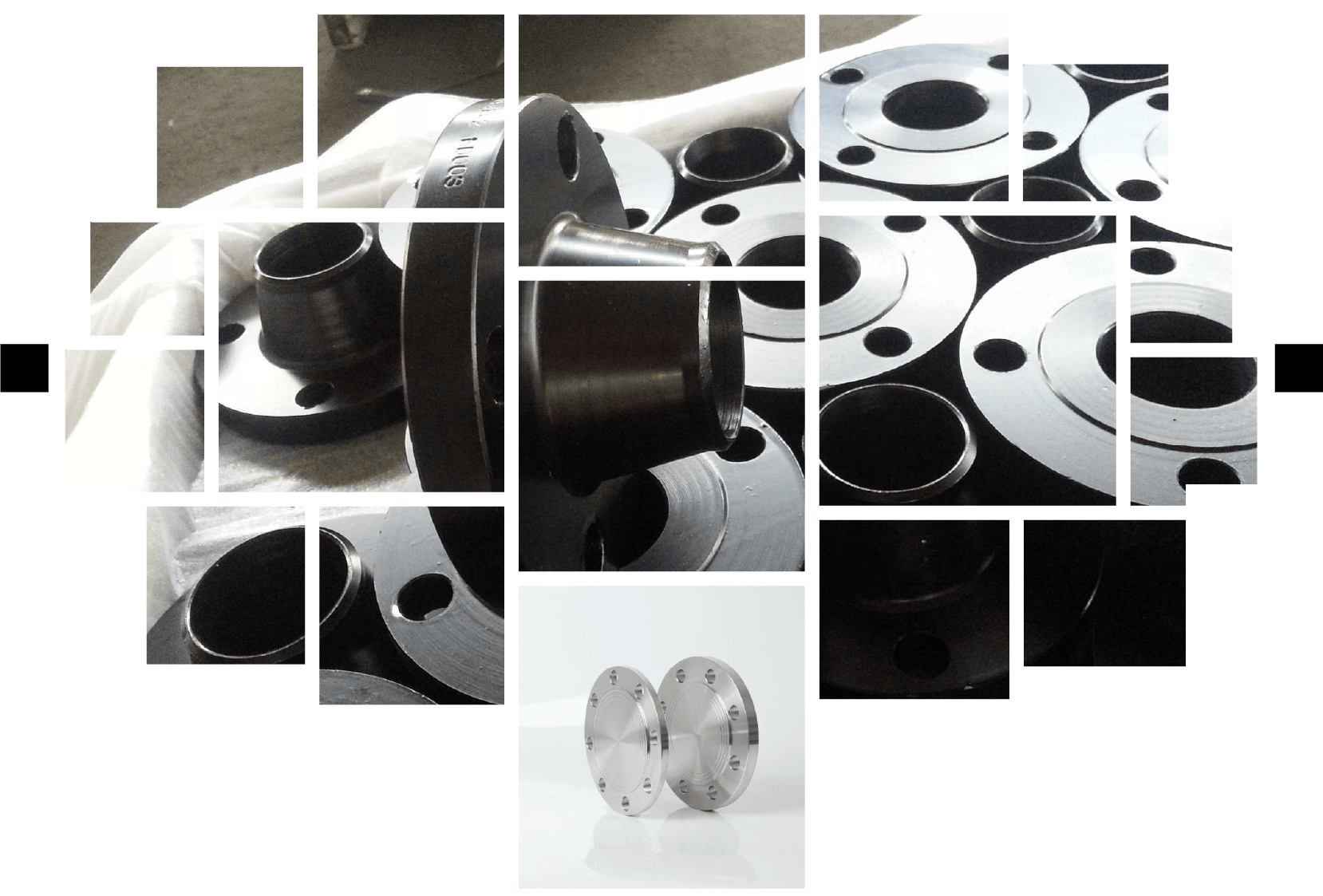

ASTM A105: American Society for Testing and Material

Carbon Steel Forgings for Piping Applications

Chemical Requirements

| Element | Composition, % |

| Carbon | 0.35 max |

| Manganese | 0.60–1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10–0.35 |

| Copper | 0.40 max |

| Nickel | 0.40 max |

| Chromium | 0.30 max |

| Molybdenum | 0.12 max |

| Vanadium | 0.05 max |

| Columbium | 0.02 max |

Mechanical Properties

| Tensile strength, min, psi [MPa] | 70 000 [485] |

| Yield strength, min, psi [MPa] | 36 000 [250] |

| Elongation in 2 in. or 50 mm, min, | 30 |

%: Basic minimum elongation for walls 5?16 in. [7.9mm] and over in thickness, strip tests. | |

| When standard round 2-in. or 50-mm gage length or smaller proportionally sized specimen with the gage length equal to 4D is used | 22 |

| For strip tests, a deduction for each 1?32 -in. [0.8-mm] decrease in wall thickness below 5?16 in. [7.9 mm] from the basic minimum elongation of the percentage points | 1.5 |

| Reduction of area, min, % | 30 |

| Hardness, HB, max | 187 |

ASTM A182:American Society for Testing and Materials Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperture Service

Chemical Requirements

| Identification | UNS | Grade | Composition % | ||||||||||

| Symbol | Designation | C | Mn | P | S | Si | Ni | Cr | Mo | Nb | Ta | Ti | |

| max | max | max | |||||||||||

| F5 | K41545 | 4~6%Cr | 0.15 max | 0.30–0.60 | 0.03 | 0.03 | 0.50 max | 0.50 max | 4.0–6.0 | 0.44–0.65 | – | – | – |

| F9 | K90941 | 9%Cr | 0.15 max | 0.30–0.60 | 0.03 | 0.03 | 0.50–1.00 | – | 8.0–10.0 | 0.90–1.10 | – | – | – |

| F91 | K90941 | 9%Cr, | 0.08–0.12 | 0.30–0.60 | 0.02 | 0.01 | 0.20–0.50 | 0.40 max | 8.0–9.5 | 0.85–1.05 | Other Elements | – | |

| 1%Mo, | Cb 0.06–0.10 | ||||||||||||

| 0.2%V+Nb&N | N 0.03–0.07 | ||||||||||||

| Al 0.04 max | |||||||||||||

| V 0.18–0.25 | |||||||||||||

| F11 | K11597 | 1.25%Cr | 0.05–0.15 | 0.30–0.60 | 0.03 | 0.03 | 0.50–1.00 | – | 1.00–1.50 | 0.44–0.65 | – | – | – |

| 0.5%Mo | |||||||||||||

| F12 | K11562 | 1%Cr, | 0.05–0.15 | 0.30–0.60 | 0.045 | 0.045 | 0.50 max | – | 0.80–1.25 | 0.44–0.65 | – | – | – |

| 0.5%Mo | |||||||||||||

| F22 | K21590 | Cr-Mo | 0.05–0.15 | 0.30–0.60 | 0.04 | 0.04 | 0.50 max | – | 2.00–2.50 | 0.87–1.13 | – | – | – |

Mechanical Properties

| Identification Symbol | Tensile Strength, | Yield Strength, min, | Elongation in 2 in. |

| min, ksi [MPa] | ksi [MPa] | [50 mm] or 4D, | |

| min, % | |||

| F5 | 70 [485] | 40 [275] | 20 |

| F9 | 85 [585] | 55 [380] | 20 |

| F91 | 85 [585] | 60 [415] | 20 |

| F11 | 60 [415] | 30 [205] | 20 |

| F12 | 60 [415] | 32 [220] | 20 |

| F22 | 60 [415] | 30 [205] | 20 |

For pipe fittings, please link: https://bekingpiping.com