Share this

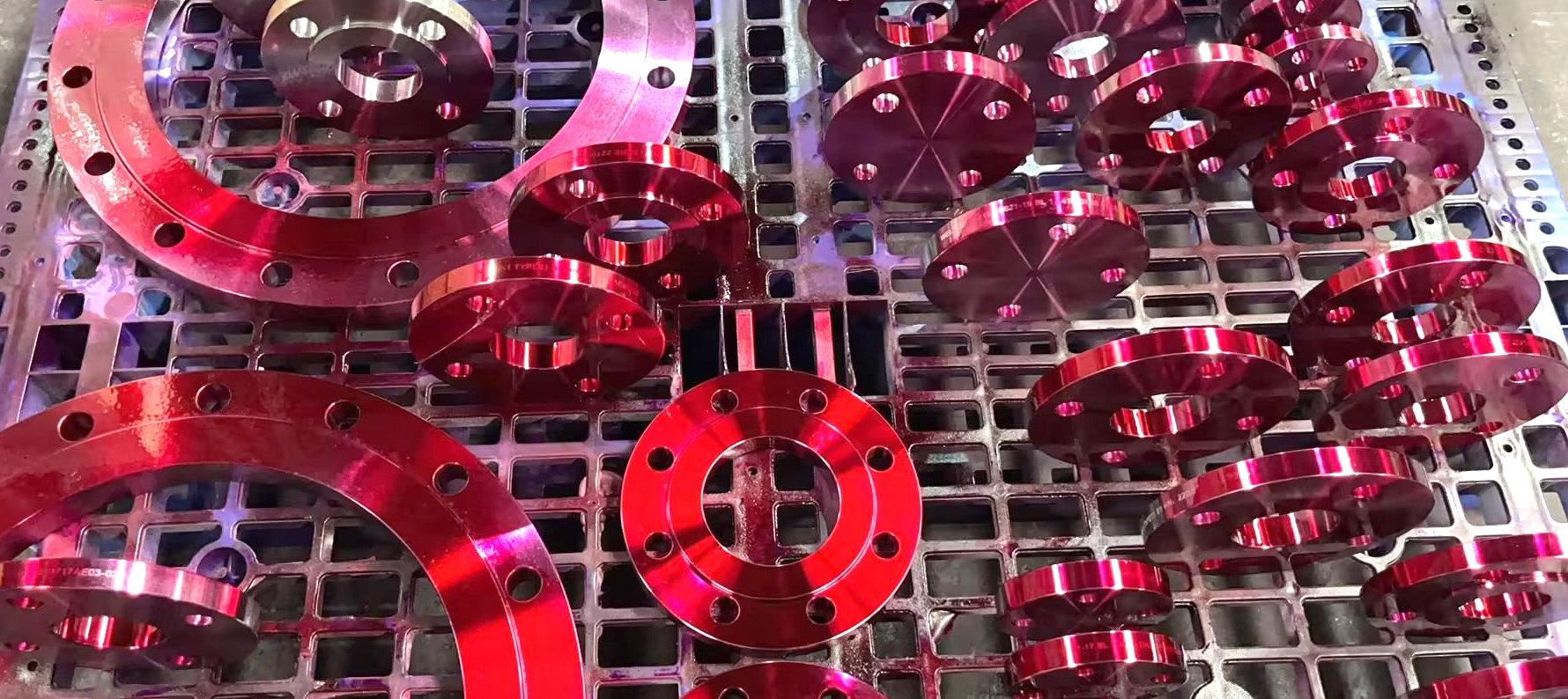

Non-destructive testing of flange fittings is a method used to inspect the connections of piping systems, aiming to detect potential defects, cracks, corrosion, and other issues without the need for dismantling or destructive testing of the pipeline. This helps to ensure the safety, stability, and efficient operation of the piping system.

Here are common non-destructive testing methods for flange fittings:

1. Ultrasonic Testing (UT): This method involves emitting ultrasonic pulses into the test piece and then receiving the reflected waves to analyze the characteristics of the echo, thereby determining the presence of defects or cracks.

2. Magnetic Particle Testing (MT): Applicable to magnetic materials, this method involves applying a magnetic field to the surface of the flange fitting and then coating it with magnetic particles. By observing the accumulation of particles at defect locations, surface cracks or flaws can be detected.

3. Dye Penetrant Testing (PT): Suitable for non-magnetic materials, this method involves applying a penetrant to the surface of the flange fitting. The penetrant seeps into surface cracks, and after wiping it off, a developer is applied to reveal the cracks.

4. Radiographic Testing (RT): In this method, the flange fitting is exposed to X-rays, and the degree of X-ray penetration is recorded using a photographic film or digital imaging technology to detect internal defects.

5. Acoustic Emission Testing (AE): This method detects potential cracks or defects in flange fittings by monitoring the acoustic emissions generated within the test piece.

6. Phased Array Ultrasonic Testing (PAUT): Utilizing multiple ultrasonic probes, this technique allows for the manipulation of the beam direction and focus, enhancing the flexibility and accuracy of the inspection.

The choice of non-destructive testing technique depends on specific factors, including the material, size of the pipeline, types of defects, available equipment, and budget. Non-destructive testing helps to identify potential issues early on, enabling prompt maintenance actions to ensure the safe operation of flange fittings. When conducting non-destructive testing, ensure that it is performed by trained and certified professionals following relevant safety standards and procedures.