Company News

Specific application of flanges in chemical projects

Flanges are commonly used in chemical engineering projects as a pipe connection method. They are...

Read MoreApplication of flanges in offshore projects

Application of flanges in offshore projects Flanges are an important component for pipeline connections and...

Read MoreCarbon steel high-pressure butt welding flange

Carbon steel high-pressure butt welding flange Executive standard: GB/T13402-2010 Specification size: 26 Pressure rating: Class300~Class900...

Read MoreFlange introduction: what is a flange?

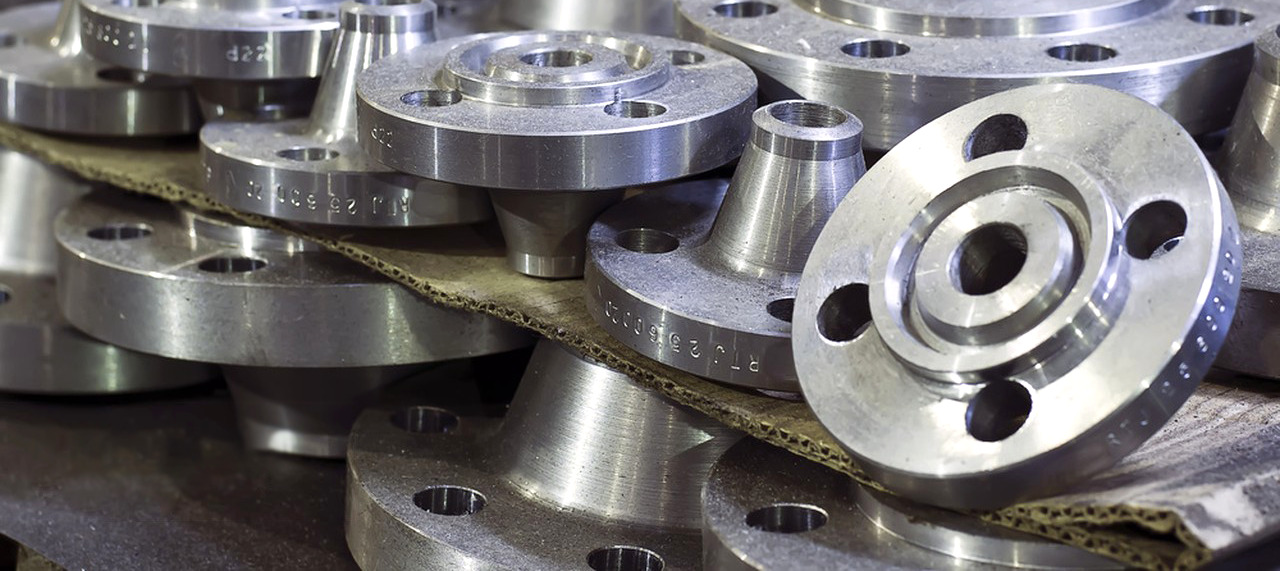

1. What is a flange? 1.1 Definition: Flange is a kind of pipe connection, used...

Read MoreUnderstanding stainless steel flanges: characteristics, classification and application range

Understanding stainless steel flanges: characteristics, classification and application range Stainless steel flange is a flange...

Read MoreFlange production process

Flanges are commonly used in piping systems to connect pipes, valves, pumps, and other equipment...

Read MoreLarge diameter flange application

Large-diameter flange connection is an important connection method for pipeline construction. Flange connection is to...

Read MoreThe two-bolt sealing surfaces compress the flange gasket and seal against each other

The two bolt sealing surfaces compress the flange gasket and seal against each other Since...

Read More