Share this

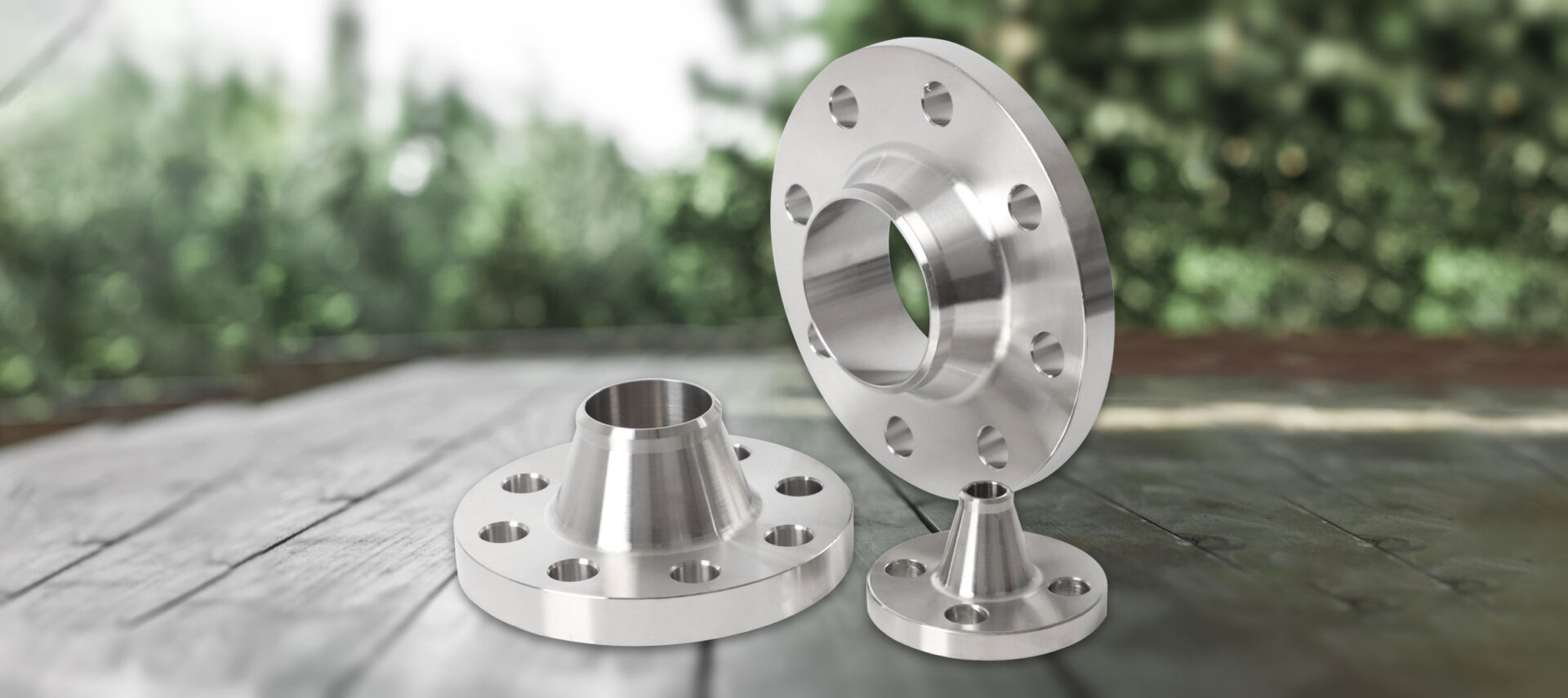

Butt welding flange refers to a flange with a neck and a round pipe transition and connected to the pipe by butt welding, which is a kind of pipe fittings. The advantages of butt welding flanges are anti-corrosion, acid and alkali resistance, long service life, etc., and the price is reasonable, the surface is smooth, acid and alkali resistance, high-temperature resistance, not easy to deform, and good sealing. The application range is for pipelines with large fluctuations in pressure or temperature or pipelines with high temperature, high pressure, and low temperature, or pipelines for transporting expensive, flammable, and explosive media.

Process standard and quality control of butt welding flange:

feeding – physical and chemical – blanking – hot forging – heat treatment – inspection – gold processing – finished product inspection – marking – finished product inspection – marking – packaging and typing – shipping. The welding installation of the butt welding flange requires double-sided welding of the flange. Not all butt welding flanges need to be welded on both sides of the inner and outer sides. There is no special requirement. Generally, only one outer welding is required. I have never seen 1/2″. Flat welding is better for welding because the pipe and flange are well-matched. Vertical, the tube will not slant.

Process standard and quality control of butt welding flange:

feeding – physical and chemical – blanking – hot forging – heat treatment – inspection – gold processing – finished product inspection – marking – finished product inspection – marking – packaging and typing – shipping.

Butt welding flange is mainly used for butt welding of flange and pipe. It has a reasonable structure, high strength, and rigidity, can withstand high temperature and high pressure, repeated bending and temperature fluctuation, and has reliable sealing performance. The nominal pressure is 0.25~2.5MPa. The welding flange adopts a concave-convex sealing surface. Butt welding flanges are widely used and popularized in pipe fittings and need to be used in accordance with the corresponding methods and methods. Butt welding flange refers to a flange with a neck and a round pipe transition and is connected to the pipe by butt welding.

Processing method: high-precision CNC lathe turning, ordinary lathe finishing, argon arc welding, etc.

Nominal pressure: sch5s, sch10s, sch20s, sch30s, sch40s, etc.

Manufacturing standards: national standard, American standard, Russian standard, Japanese standard, etc.

Connection method: flange nut, bolt connection.

International butt welding flanges are anti-corrosion, acid and alkali resistance, long service life, etc., reasonable price calculation, smooth surface, acid and alkali resistance, high-temperature resistance, reasonable price calculation, beautiful appearance, and strong texture performance.

For pipe fittings, please link: https://bekingpiping.com