Share this

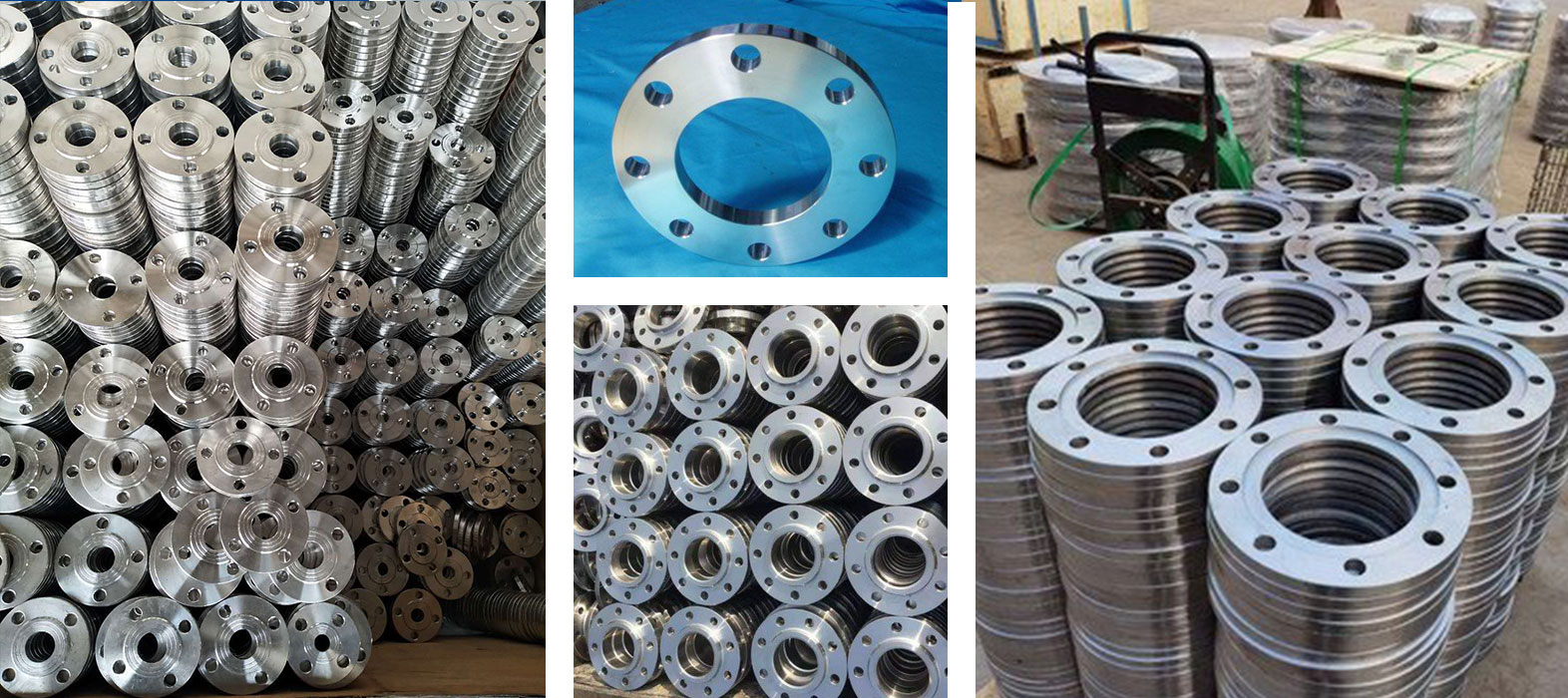

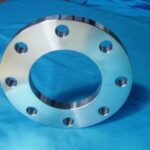

Pipe flanges, gaskets and fasteners are collectively referred to as flange joints. Flange joint is a kind of component that is widely used in engineering design and involves a wide range of surfaces. It is an essential part of piping design, pipe fittings and valves, and an essential component of equipment and equipment parts (such as manholes, sight glass level gauges, etc.).

In addition, other professions such as industrial furnaces, thermal engineering, water supply and drainage, heating and ventilation, automatic control, etc., also often use flange joints. Raw materials: forged steel, WCB carbon steel, stainless steel, 316L, 316, 304L, 304, 321, chrome molybdenum steel, chrome molybdenum vanadium steel, molybdenum titanium, rubber-lined, fluorine-lined raw materials.

Types:

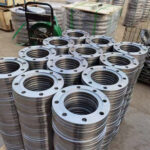

flat welding flange, neck flange, butt welding flange, ring connection flange, socket flange, and blind plate, etc. The performance standards include GB series (standard), JB series (machinery department), HG series (chemical industry department), ASME B16.5 (American standard), BS4504 (British standard), DIN (German standard), JIS (Japanese standard).

World pipe flange specification system:

There are two main systems for pipe flange specifications in the world, namely the European pipe flange system represented by German DIN (including the former Soviet Union) and the American pipe flange represented by American ANSI pipe flanges system. In addition, there are Japanese JIS pipe flanges, but they are generally only used for public works in petrochemical equipment, and have less influence in the world.

For pipe fittings, please link: https://bekingpiping.com