Share this

Most people associate flanged pipes with the oil industry. However, they offer a lot more functionality than you may realize. Another thing about them is that they have been around for a while. In fact, humans have a long history of using flanged pipes as a means of transportation to meet various needs. Here’s what you might want to know about the history of flanged piping.

History of flanged pipes

early reference

The earliest-mentioned pipelines span different parts of the globe. For example, Babylonian settlements used clay sewer pipes around 4,000 BC. On the other hand, the Romans and Greeks used them for their water supply. They also use them as storm sewer systems. Some civilizations, like the Mayans, even used them for pressurized water piping systems without long-weld necks. If you look through history, you’ll also find stone implement pipes that were used by the Han Dynasty around 189 AD to supply water to the imperial palace. It will be very interesting to see how these different cultures independently develop pipelines to serve various purposes.

The Rise of Pipeline Construction

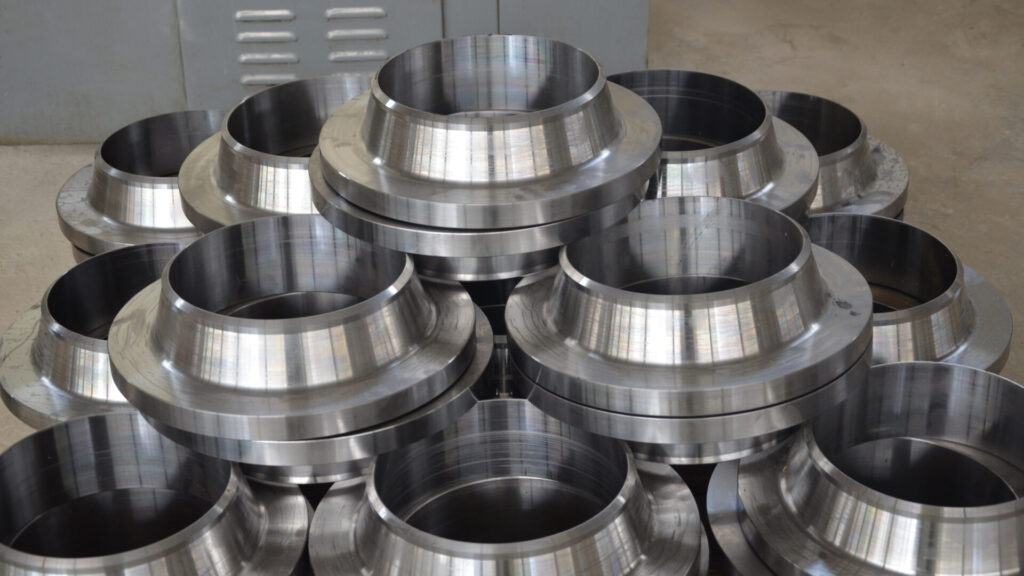

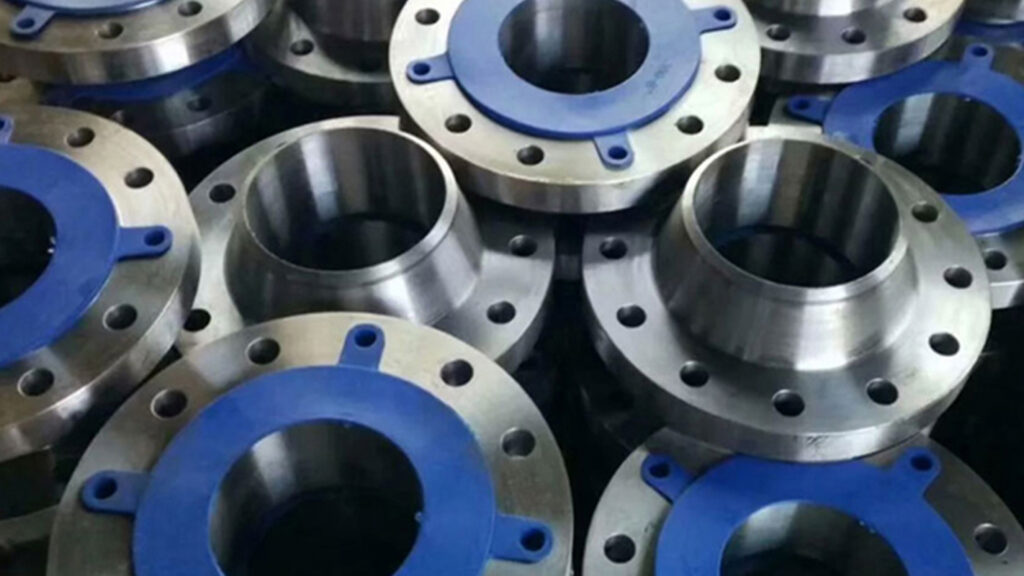

What made people start building flanged pipe as we know it today? Well, the simple answer is the Industrial Revolution. The main focus of pipeline construction starts with water. Over time, people started to realize that they could do more with pipes. The rise of pipeline construction over the past two centuries has been fueled by the flow of natural gas and oil. In the 19th century, homes needed water, gas, and oil. This led to the development of technologies such as steel pipes and long weld necks. These have greater force, allowing one to push liquids at higher pressures over longer distances. At this time, pipe flanges were invented at the same time, which brought more convenience to pipeline construction.

The origin of the flange pipe

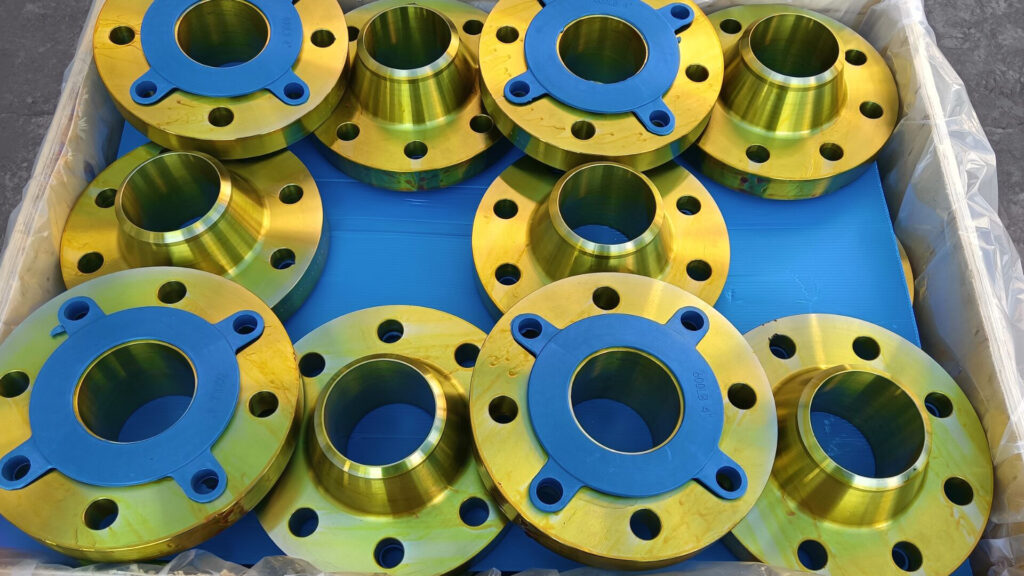

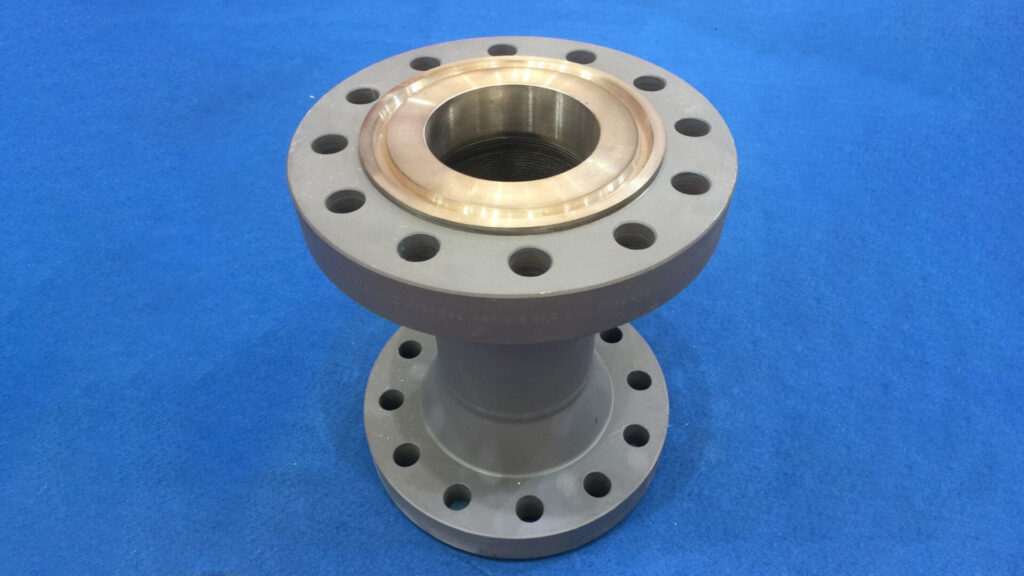

The casting of flanges first appeared in 1809 by the British Elkhart, and it was not until the early twentieth century that flanges were gradually adopted and promoted. In the 1930s, our country also began to use and cast flanged pipes and cylindrical castings such as iron pipes, copper sleeves, cylinder sleeves, and bimetallic steel-backed copper sleeves. The flange casting method is also used very effectively in the production of heat-resistant steel roller tables, blanks of some special steel seamless steel pipes, and paper machine drying drums. At present, a highly mechanized and automated flange casting machine has been produced, and a mass-produced mechanized flange casting workshop has been established. Almost all casting alloys can be used for flange casting production. The minimum inner diameter of flange castings can reach 8mm, the diameter can reach 3m, the length of castings can reach 8m, and the weight range of flange castings ranges from a few cattle to tens of thousands of cattle ( A few tenths of a kilogram to more than ten tons).

modern flange pipe

As the 20th century progressed, people began laying pipes at a rapid pace. Not only did they start burying steel pipes in the ground, but they also built concrete and asbestos pipes. These materials are transport centers for water, gas, sewage, oil, and other things. As it turns out, the 1950s and 1960s were the most important period for pipeline construction. During that time period, 44% of all pipelines in the United States were built. There are a lot of developments happening in the plumbing space right now. For example, according to a study conducted by the University of Toledo, forged parts have 26% higher tensile strength than similar cast parts. As a result, people realized that pipes made from forged parts performed better. People continue to build pipelines to serve various purposes around the world.

For pipe fittings, please link: https://bekingpiping.com