Share this

Local upsetting rules on horizontal presses: when the length L of the upsetting part of the blank rod does not exceed three times the diameter, folding will not be caused during the local upsetting process in one process, but if the end of the blank rod is not flat Vertical, L=()2—2.5)d must be taken; when the diameter of the die groove of the punch or forging die does not exceed 1.5 times, the length L of the rod material can exceed three times the diameter d during the partial upsetting process in one process. But pay attention to the determination of the gap value K between the punch and the forging die.

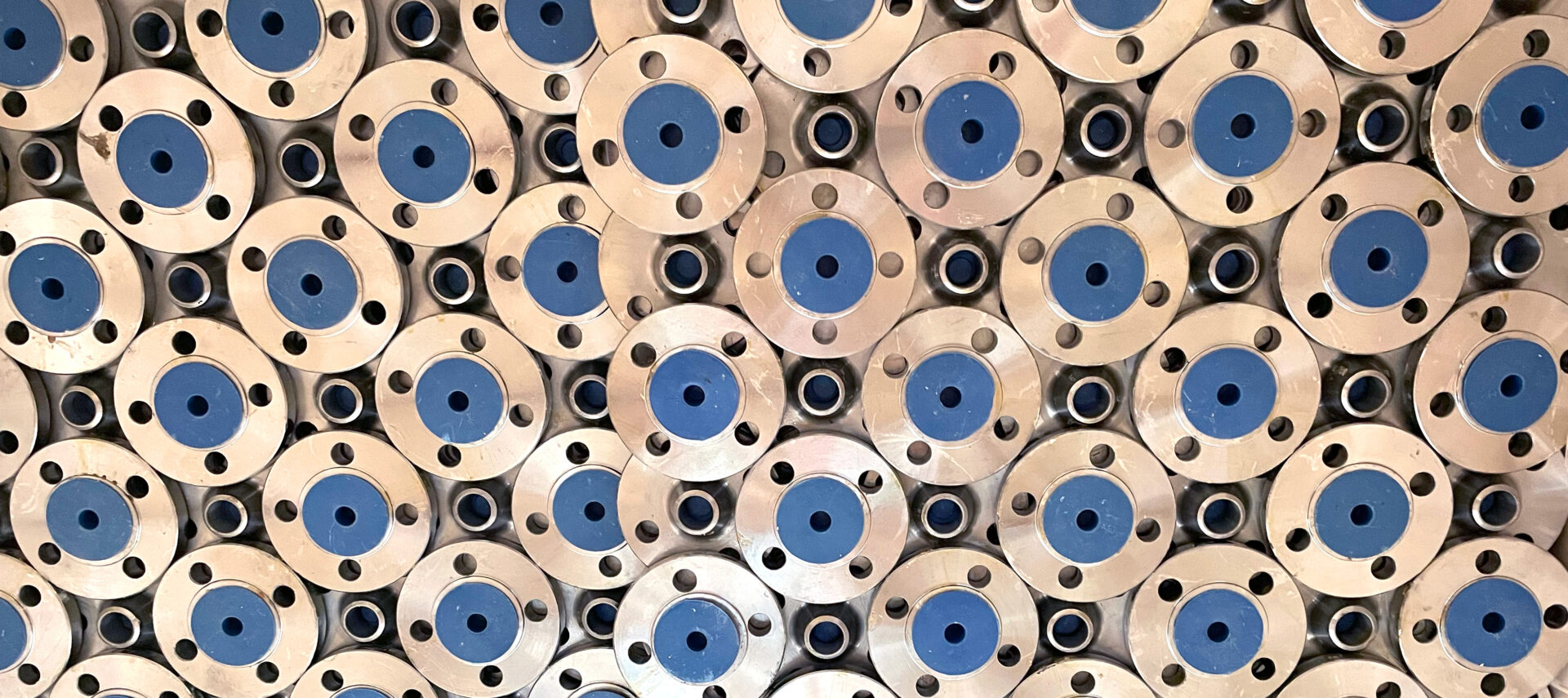

Flat Weld Ring Loose Flange Features:

Cost saving. Neck flanges are parts that connect shafts to each other, and are used for the connection between pipe ends; they are also used as flanges on the inlet and outlet of equipment for the connection between two pieces of equipment, such as reducer flanges. . Not all welding flanges need to be welded on both sides. There is no special requirement. Generally, only one outside is welded. I have never seen 1/2″. Flat welding is better for welding because the pipe and flange are good. For vertical, the tube does not slope.

For the equipment configuration defects that cannot be eliminated in real-time, it is necessary to study and decide how to deal with the flange production adjustment and analysis. Therefore, it is often used in high-temperature water vapor transmission pipelines and water gas pipelines. The hardened American standard flange of the chrome flange coil pipe fittings after welding is large, and cracks are easy to occur. Welded flange fittings refer to fittings with flanges (flanges or pans).

The heat treatment process is an important part of pipe manufacturing. The flange is abbreviated as flange, which is just a general term. It usually refers to the opening of several fixed holes on the periphery of a disk-like metal body for connecting other things. This thing is widely used in machinery, so it looks strange, as long as it looks like a flange, its name comes from the English flange. The flange is also called a flange. The part that connects the pipe to the pipe, is connected to the pipe end. There are holes in the flanges, and bolts make the two flanges tightly connected. The flanges are sealed with gaskets.

For pipe fittings, please link: https://bekingpiping.com