Share this

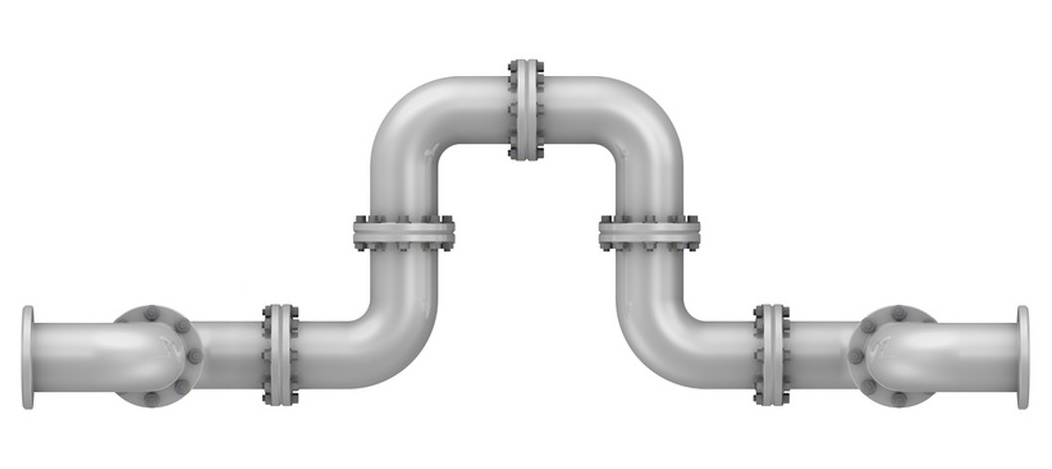

Flange connection is usually used in the connection of pipelines, the connection of sealed containers, etc. The function of a flange is to ensure the good sealing of containers or pipelines and prevent the leakage of gas or liquid. Therefore, in general, the sealing structure of a flange connection consists of the flange,

Composed of gaskets and fasteners.

Flanges are referred to as flanges for short, and they are just a general term. They usually refer to opening several holes for fixing on the periphery of a disc-like metal body for connecting other things.

This thing is widely used in machinery, so it looks strange, as long as it looks like it is called a flange.

The butt welding flange produced by the butt welding flange adopts certain technical parameters and requirements for production and use during production and production, so as to ensure that it can be used and promoted according to certain methods and principles and adopts certain process methods and principles for production and use.

Welding strictly guarantees good quality in use.

This structure is a more basic flange connection structure, which is usually used for pipeline flange connection structure or container flange connection structure. In this connection structure, two flanges of the same size are connected by gaskets, and fasteners There are only sealing gaskets and no other components between the flanges. The temperature and pressure loads of the two flanges are exactly the same.

This type of flange can be designed and calculated directly according to the calculation formula specified in the standard.

In addition, for shell-and-tube heat exchangers, the sealing structure of the tube-box flange connection is different from the container flange or pipeline flange connection structure. The two flanges are separated by the tube plate.

When the sealing gaskets, temperature loads, and pressure loads on both sides are inconsistent, the bolt force of the flange, gasket reaction force and other loads cannot be simply Calculated according to the formula specified in the standard.

Therefore, when we use flanges, we can refer to the relevant regulations of the pressure vessel. For the design of paired flanges on both sides of the tube sheet of a similar U-shaped tube heat exchanger, due to the pressure and temperature on both sides and the gasket used may Different, must have the necessary accuracy calculation before choosing the flange connection.

For pipe fittings, please link: https://bekingpiping.com