Share this

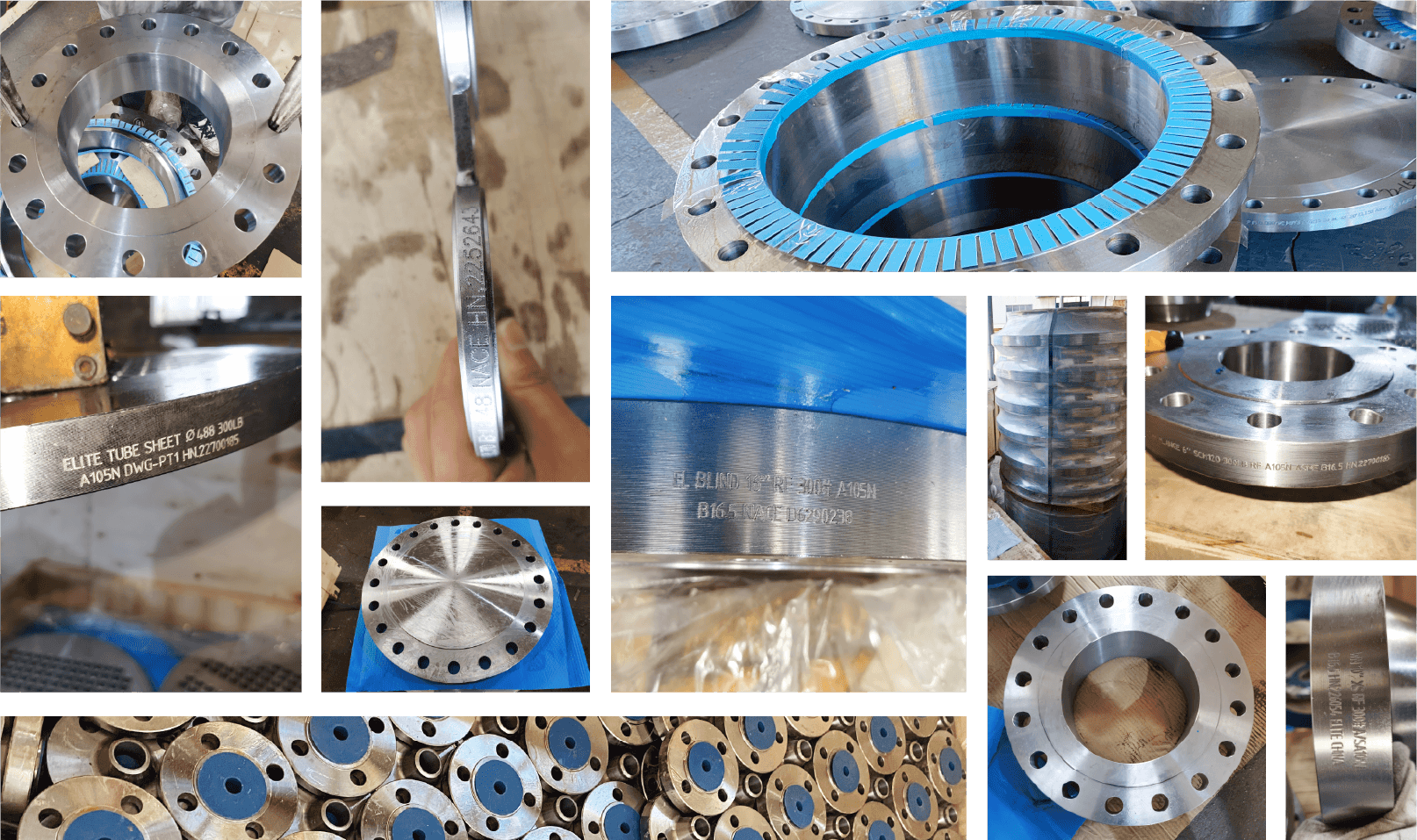

Butt Welding Flange Processing Technology and Related Performance

A buttwelding flange is a common type of pipe fitting that joins pipes to valves, pipes to pipes, and other connections through welding. Here is an introduction to the welding flange processing technology and related performance:

Butt Welding Flange Processing Technology:

1. Material preparation: Select appropriate welding materials, typically using materials similar to or the same as the pipes or valves being connected.

2. Preparation work: Clean and treat the surfaces of the pipes and valves to be connected, ensuring they are smooth and free from impurities such as oil and oxides.

3. Welding operation: Employ suitable welding methods such as manual arc welding, gas-shielded welding, etc., for the welding process. Commonly used welding methods include shielded metal arc welding, tungsten inert gas welding, etc.

4. Inspection and rectification: After completing the welding, inspect the weld seam using techniques like X-ray inspection, ultrasonic testing, etc. If any defects or non-conformities are detected, rectify or redo the welding as necessary.

Related Performance of Butt Welding Flanges:

1. Pressure resistance: Welding flanges are typically subjected to internal pressure within the pipe system. Therefore, the welded joints and welding quality of welding flanges need to possess good pressure resistance to ensure the safety of the system.

2. Sealing performance: The connecting parts of butt welding flanges require excellent sealing performance to prevent leakage in the pipe system. The quality of the weld seam and the selection of sealing gaskets are crucial for achieving effective sealing.

3. Strength and reliability: The welded connections of butt welding flanges need to have sufficient strength and reliability to withstand internal pressure and external loads in the pipe system. The quality of the weld seam, welding process, and material selection all influence strength and reliability.

4. Corrosion resistance: Butt Welding flanges may be exposed to corrosive environments such as chemical media, high temperatures, or high humidity. Therefore, the selection of appropriate welding materials and implementing corrosion protection measures are essential for enhancing the corrosion resistance of welding flanges.

It is important to note that the butt welding flange processing technology and related performance may vary based on specific applications and standard requirements. Therefore, in practical applications, the selection and design should be made based on the specific circumstances. Additionally, for welding flanges with special requirements, adherence to specific specifications and standards may be necessary.