Share this

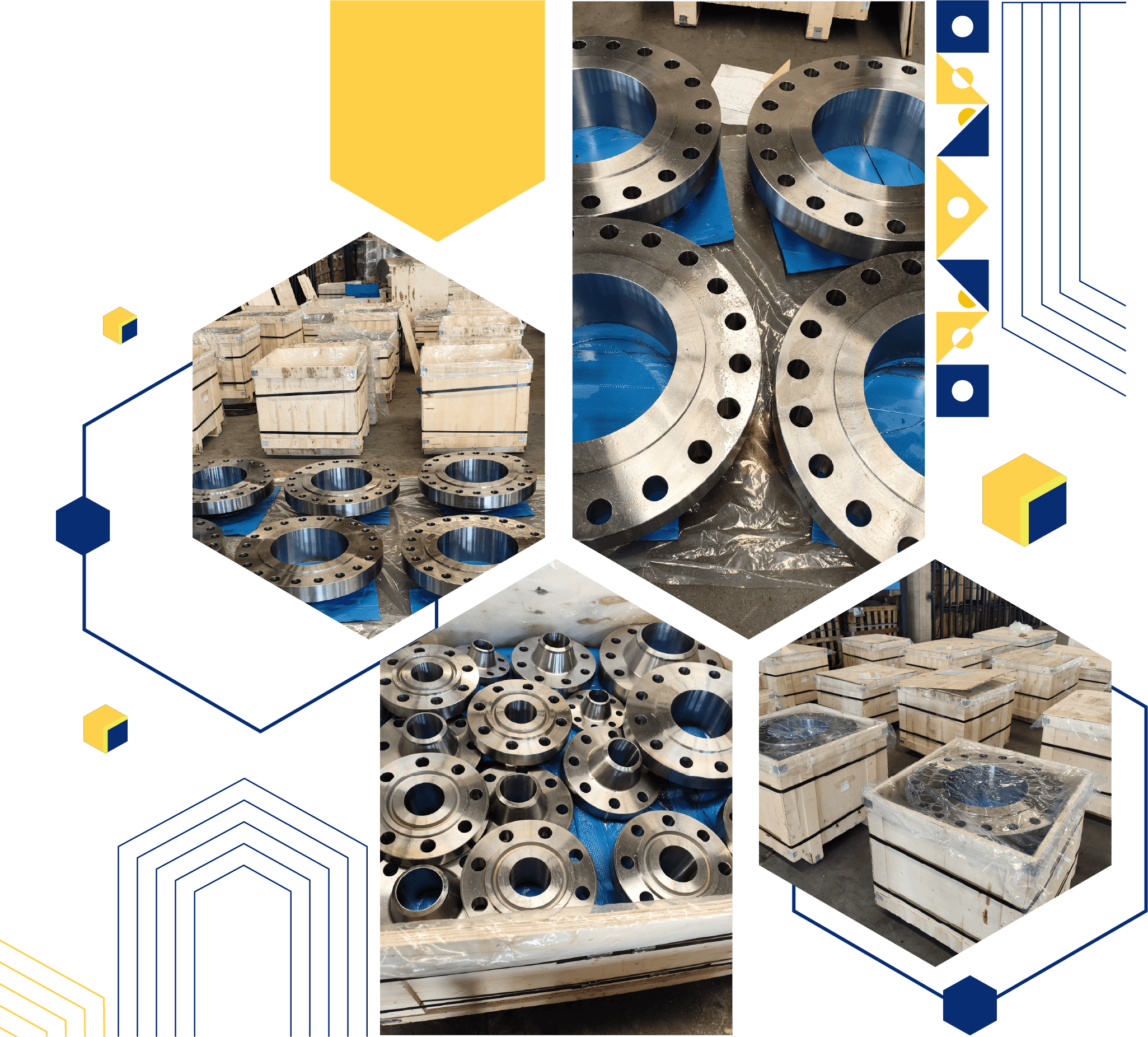

Application of flanges in offshore projects

Flanges are an important component for pipeline connections and are widely used in offshore projects. Here are some common applications of flanges in offshore projects:

Pipeline connection: In offshore projects, flanges are usually used to connect various pipes and valves. These pipelines can be used to transport crude oil, natural gas, water and other substances, while flanges are used to connect the pipelines and ensure the sealing and reliability of the joints.

Offshore platform construction: Flanges are also used in the construction of offshore platforms, such as oil drilling platforms, wind power platforms, etc. Flanges can connect various pipelines and equipment to ensure the stability and safety of offshore platforms.

Submarine pipeline connection: Flanges can also be used to connect subsea pipelines. These pipelines are usually used to transport crude oil, natural gas and other substances, and flanges are used to connect the pipelines and ensure the sealing and reliability of the joints.

Offshore pipeline repairs: In offshore projects, pipeline repairs and replacements often need to be done underwater. At this time, the flange can also play a role. For example, flanges can be used to connect pipes of different lengths, allowing the replacement of damaged pipe parts underwater.

In conclusion, flanges play an important role in offshore projects, ensuring the connection and safety of pipelines and equipment, and are also an indispensable component in offshore engineering.

For pipe fittings, please link: https://bekingpiping.com