Share this

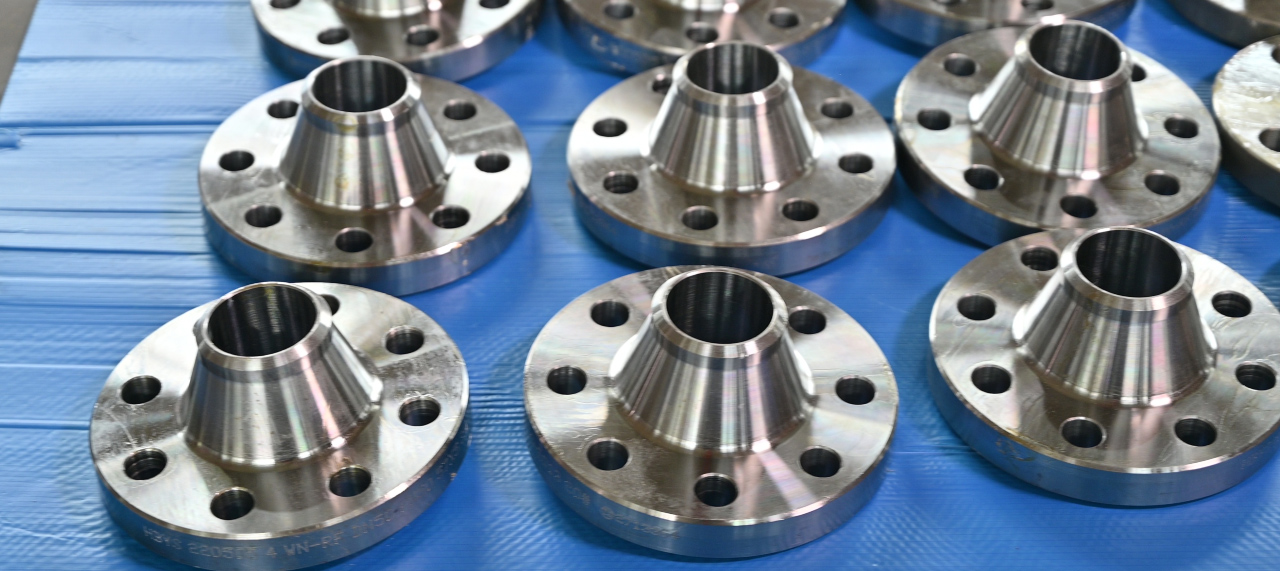

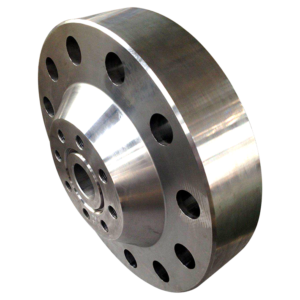

Due to the unique impact strength performance of the alloy steel flange, it has been significantly improved compared with other solid-wall pipes.

Its ring stiffness is equivalent to that of solid-wall pipes, and its service life is long: the service life of the pipe reaches 50 years under the rated operating temperature and pressure.

More than one year, with anti-ultraviolet, no fading, good corrosion resistance: except for a few hydrogenating agents, it can resist the corrosion of various chemical media, the flange has excellent acid and alkali resistance, corrosion resistance, will not rust, will not Corrosion, no bacteria, no electrochemical corrosion.

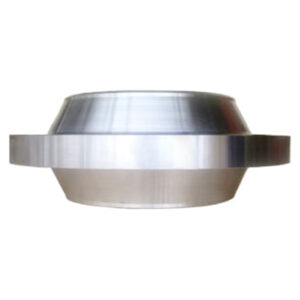

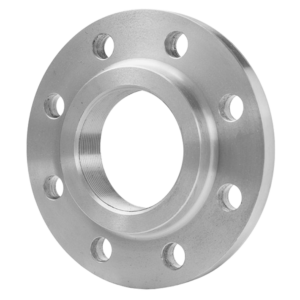

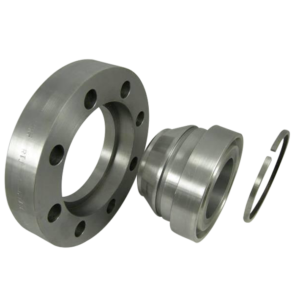

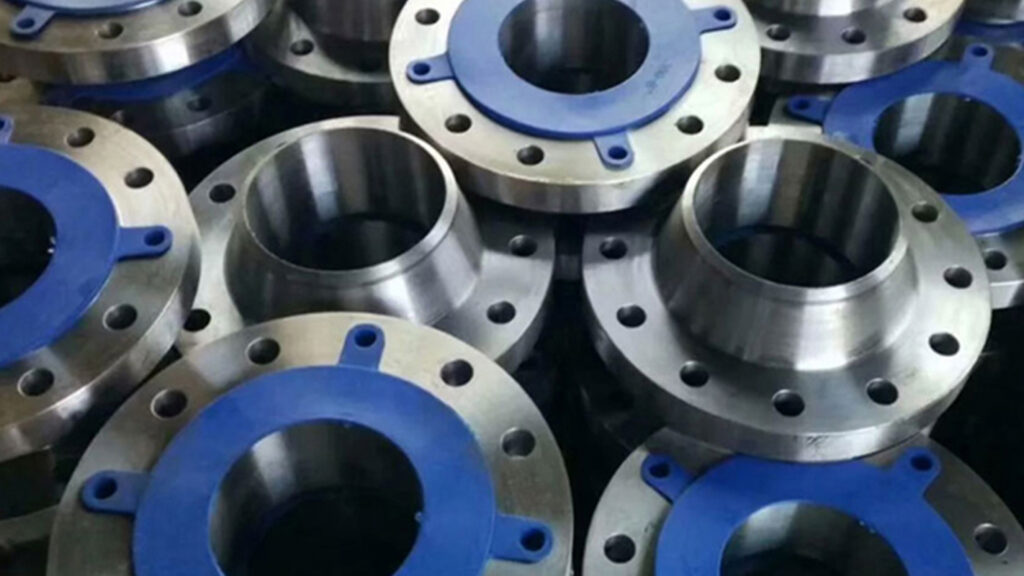

But the price is relatively high, the reason is that the production process of the product is complex, sliding flange: the sliding flange has a lower hub because the pipe enters the single flange before welding, which is welded inside and outside to provide sufficient strength, To prevent leakage, sliding flanges are matched with slightly larger outer diameter pipes, and they are better than welded neck flanges.

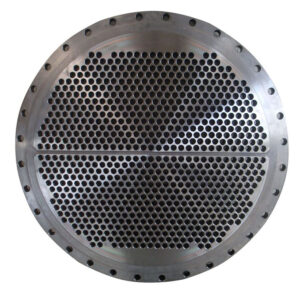

There are basket type, double ear type, flange type, basket type filter cartridge, screw interface type and other styles. Metal filter net barrel net tube net barrel filter tube is welded by stainless steel mesh, stainless steel perforated mesh, iron mesh and stainless steel plate.

It can be single-layer welded or multi-layer welded, and after single-layer welding, the metal filter mesh, tube, net, barrel, filter element, and filter tube can be superimposed and interspersed together to form a multi-layer filter.

The shorter the cleaning time of the set time, the better. If the initial dust layer is insufficient, the number of cleanings can be extended. If the pressure difference control is used, the stability of the inlet and outlet pressure settings of the dust collector can be improved.

Top-loading filter cartridges are removable cylindrical devices that are closed at the top and bottom and surrounded by filter media.

It belongs to deep filtration, and its characteristic is that the solid particles of the suspension are smaller than the pore diameter of the filter medium. Particle filtration is trapped and adhered to the wall of the pore by the impact and extrusion of the slender curved pores in the filter medium and the fluid. Galvanized barbed wire, stainless steel flanges, steel rings and other materials. Style: single layer, multi-layer: with bottom, without bottom

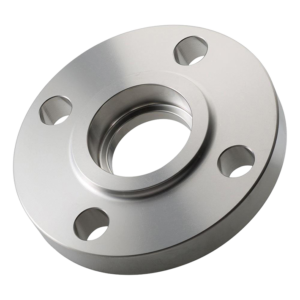

According to the mechanical (JB) industry standard: integral flange, butt welding flange, plate type flat welding flange, butt welding ring plate type loose sleeve flange, flat welding ring plate type loose sleeve flange, flanging ring plate type loose sleeve flange, flange cover.

Hydrogen elimination treatment should also be carried out, which is the most important link in the entire welding process. Hydrogen elimination treatment is directly related to hydrogen-induced cracking and sulfide stress cracking of the entire welding joint.

Specifically, the temperature in the hydrogen elimination treatment should be controlled between 250°C and 350°C, and generally requires constant temperature treatment for about 2 hours.

After the flange welding of the anti-sulfur pipe fittings is completed, the welded joints should be dehydrogenated in time, and the temperature should be higher than 100°C before the dehydrogenation treatment.

If there is an accident in the specific operation, for example, when the welding joint is completed for 2/3 or more, but it is forced to stop halfway, then the hydrogen removal treatment should be carried out immediately after welding.

For pipe fittings, please link: https://bekingpiping.com