Share this

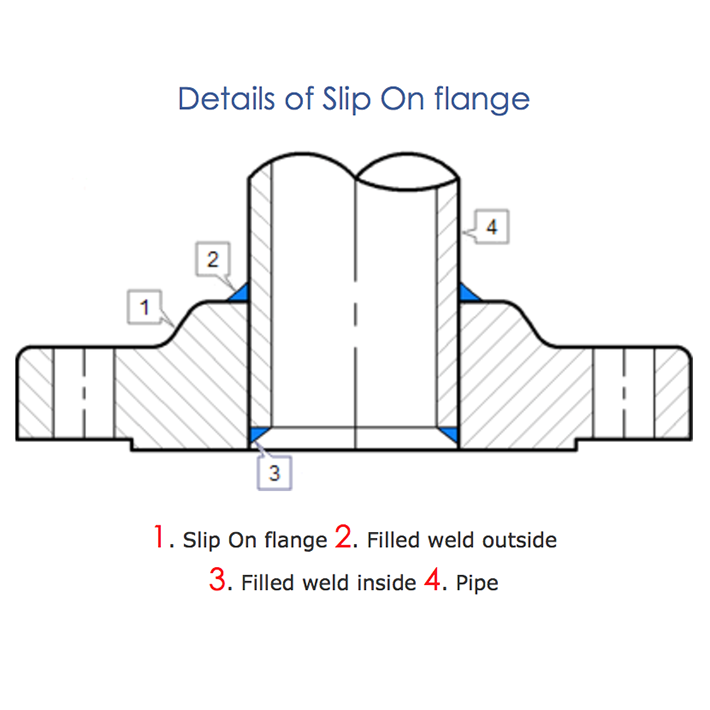

A slip-on flange is positioned so the inserted end of the pipe or fitting is set short of the flange face by the thickness of the pipe wall plus 1/8 of an inch, which thus allows for a fillet weld inside the SO flange equal without doing any damage to the flange face. The back or outside of the slip-on flange or SO flange is also welded with a fillet weld.

Molding Process:

Through the forging process, using mold forming, and then through machining to complete the product processing.

Production Scope:

DN15-DN2000

Main Material:

Carbon steel: A105, SS400, SF440 RST37.2, S235JRG2, P250GH, C22.8, Stainless Steel: F304 F304L F316 F316L 316Ti, Copper etc.

Application Condition:

Widely used in Petrochemical, Coal Chemical, Refining, Oil and Gas Transmission, Marine Environment, Power, Heating and Other projects

Product Characteristics:

The slip-on flange is positioned so the inserted end of the pipe or fitting is set short of the flange face by the thickness of the pipe wall plus 1/8 of an inch, which thus allows for a fillet weld inside the SO flange equal without doing any damage to the flange face. The back or outside of the slip-on flange or SO flange is also welded with a fillet weld.

Type: SO Forged Flange

Standard:ANSI, JIS, DIN, BS4504, SABS1123, EN1092-1, UNI, AS2129, GOST-12820

Pressure:ANSI class 150, 300, 600, 1500, 2500, DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

Packing: No Fumigate or Fumigate Plywood/Wood Pallet or Case

Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint, Zinc, Hot dipped Galvanized.

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national, and provincial reputation

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 150lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 150LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | ||

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 22.40 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 27.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 34.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 43.20 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 49.50 | 98.60 | 15.80 | 4 | 1/2″ | 1.4 | 3.1 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 62.00 | 120.70 | 19.10 | 4 | 5/8″ | 2.2 | 4.8 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 74.70 | 139.70 | 19.10 | 4 | 5/8″ | 3.5 | 7.7 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 90.70 | 152.40 | 19.10 | 4 | 5/8″ | 3.8 | 8.4 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 103.40 | 177.80 | 19.10 | 8 | 5/8″ | 5 | 11 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 116.10 | 190.50 | 19.10 | 8 | 5/8″ | 5.6 | 12.3 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 143.80 | 215.90 | 22.40 | 8 | 3/4″ | 6.5 | 14.3 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 170.70 | 241.30 | 22.40 | 8 | 3/4″ | 8.1 | 18 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 221.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 276.40 | 362.00 | 25.40 | 12 | 7/8″ | 18.4 | 40 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 327.20 | 431.80 | 25.40 | 12 | 7/8″ | 28.5 | 63 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 359.20 | 476.30 | 28.50 | 12 | 1″ | 37.5 | 83 |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 410.50 | 539.80 | 28.50 | 16 | 1″ | 44.5 | 98 |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 461.80 | 577.90 | 31.80 | 16 | 1 1/8″ | 54 | 119 |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 513.10 | 635.00 | 31.80 | 20 | 1 1/8″ | 72 | 158 |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 616.00 | 749.30 | 35.10 | 20 | 1 1/4″ | 95 | 209 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 300lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 300LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.4 | 66.5 | 15.7 | 4 | 1/2″ | 0.7 | 1.5 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 27.7 | 82.6 | 19.1 | 4 | 5/8″ | 1.2 | 2.6 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 34.5 | 88.9 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1-1/4″ | 32 | 133. 5 | 19.1 | 63.5 | 63.5 | 26.9 | 43.2 | 98.6 | 19.1 | 4 | 5/8″ | 1.8 | 4 |

| 1-1/2″ | 40 | 155. 5 | 20.6 | 69.9 | 73.2 | 30.2 | 49.5 | 114.3 | 22.4 | 4 | 5/8″ | 2.7 | 6 |

| 2″ | 50 | 165. 0 | 22.4 | 84.1 | 91.9 | 33.3 | 62 | 127 | 19.1 | 8 | 5/8″ | 3.2 | 7 |

| 2-1/2″ | 65 | 190. 5 | 25.4 | 100.1 | 104.6 | 38.1 | 74.7 | 149.4 | 22.4 | 8 | 3/4″ | 4.5 | 9.9 |

| 3″ | 80 | 209. 5 | 28.4 | 117.3 | 127 | 42.9 | 90.7 | 168.1 | 22.4 | 8 | 3/4″ | 5.9 | 13 |

| 3-1/2″ | 90 | 228. 5 | 30.2 | 133.4 | 139.7 | 44.5 | 103. 4 | 184.2 | 22.4 | 8 | 3/4″ | 7.5 | 16.5 |

| 4″ | 100 | 254. 0 | 31.8 | 146.1 | 157.2 | 47.8 | 116. 1 | 200.2 | 22.4 | 8 | 3/4″ | 10 | 22 |

| 5″ | 125 | 279. 5 | 35.1 | 177.8 | 185.7 | 50.8 | 143. 8 | 235 | 22.4 | 8 | 3/4″ | 12.5 | 27.5 |

| 6″ | 150 | 317. 5 | 36.6 | 206.2 | 215.9 | 52.3 | 170. 7 | 269.7 | 22.4 | 12 | 3/4″ | 16.5 | 36.4 |

| 8″ | 200 | 381. 0 | 41.1 | 260.4 | 269.7 | 62 | 221. 5 | 330.2 | 25.4 | 12 | 7/8″ | 25.5 | 56 |

| 10″ | 250 | 444. 5 | 47.8 | 320.5 | 323.9 | 66.5 | 276. 4 | 387.4 | 28.4 | 16 | 1″ | 35 | 77 |

| 12″ | 300 | 520. 5 | 50.8 | 374.7 | 381 | 73.2 | 327. 2 | 450.9 | 31.8 | 16 | 1 1/8″ | 52 | 115 |

| 14″ | 350 | 584. 0 | 53.8 | 425.5 | 412.8 | 76.2 | 359. 2 | 514..4 | 31.8 | 20 | 1 1/8″ | 73 | 161 |

| 16″ | 400 | 647. 5 | 57.2 | 482.6 | 469.9 | 82.6 | 410. 5 | 571.5 | 35.1 | 20 | 1 1/4″ | 88 | 194 |

| 18″ | 450 | 711. 0 | 60.5 | 533.4 | 533.4 | 88.9 | 461. 8 | 628.7 | 35.1 | 24 | 1 1/4″ | 115 | 253 |

| 20″ | 500 | 774. 5 | 63.5 | 587.2 | 584.2 | 95.3 | 513. 1 | 685.8 | 35.1 | 24 | 1 1/4″ | 139 | 306 |

| 24″ | 600 | 914. 5 | 69.9 | 701.5 | 692.2 | 106. 4 | 616. 0 | 812.8 | 41.1 | 24 | 1 1/2″ | 212 | 467 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 600lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 600LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.9 | 66.5 | 15.7 | 4 | 1/2″ | 0.8 | 1.8 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 28.2 | 82.6 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 35.1 | 88.9 | 19.1 | 4 | 5/8″ | 1.7 | 3.7 |

| 1-1/4″ | 32 | 133. 5 | 20.6 | 63.5 | 63.5 | 28.4 | 43.7 | 98.6 | 19.1 | 4 | 5/8″ | 2.1 | 4.6 |

| 1-1/2″ | 40 | 155. 5 | 22.4 | 69.9 | 73.2 | 31.8 | 50 | 114.3 | 22.4 | 4 | 3/4″ | 3.1 | 6.8 |

| 2″ | 50 | 165. 0 | 25.4 | 84.1 | 91.9 | 36.6 | 62.5 | 127 | 19.1 | 8 | 5/8″ | 3.9 | 8.6 |

| 2-1/2″ | 65 | 190. 5 | 28.4 | 100.1 | 104.6 | 41.1 | 75.4 | 149.4 | 22.4 | 8 | 3/4″ | 5.4 | 11.9 |

| 3″ | 80 | 209. 5 | 31.8 | 117.3 | 127 | 46 | 91.4 | 168.1 | 22.4 | 8 | 3/4″ | 7.3 | 16.1 |

| 3-1/2″ | 90 | 228. 5 | 35.1 | 133.4 | 139.7 | 49.3 | 104.1 | 184.2 | 25.4 | 8 | 7/8″ | 9 | 19.8 |

| 4″ | 100 | 273. 0 | 38.1 | 152.4 | 157.2 | 53.8 | 116.8 | 215.9 | 25.4 | 8 | 7/8″ | 16.5 | 36..4 |

| 5″ | 125 | 330. 0 | 44.5 | 189 | 185.7 | 60.5 | 144.5 | 266.7 | 28.4 | 8 | 1″ | 28.5 | 62.8 |

| 6″ | 150 | 355. 5 | 47.8 | 222.3 | 215.9 | 66.5 | 171.5 | 292.1 | 28.4 | 12 | 1″ | 36.2 | 79.8 |

| 8″ | 200 | 419. 0 | 55.6 | 273.1 | 269.7 | 76.2 | 222.3 | 349.3 | 31.8 | 12 | 1 1/8″ | 51.5 | 114 |

| 10″ | 250 | 508. 0 | 63.5 | 342.9 | 323.9 | 85.9 | 277.4 | 431.8 | 35.1 | 16 | 1 1/4″ | 76.2 | 168 |

| 12″ | 300 | 559. 0 | 66.5 | 400.1 | 381 | 91.9 | 328.2 | 489 | 35.1 | 20 | 1 1/4″ | 89.5 | 197 |

| 14″ | 350 | 603. 5 | 69.9 | 431.8 | 412.8 | 93.7 | 360.2 | 527.1 | 38.1 | 20 | 1 3/8″ | 102 | 225 |

| 16″ | 400 | 686. 0 | 76.2 | 495.3 | 469.9 | 106. 4 | 411.2 | 603.3 | 41.1 | 20 | 1 1/2″ | 150 | 330 |

| 18″ | 450 | 743. 0 | 82.6 | 546.1 | 533.4 | 117. 3 | 462.3 | 654.1 | 44.5 | 20 | 1 5/8″ | 180 | 397 |

| 20″ | 500 | 813. 0 | 88.9 | 609.6 | 584.2 | 127. 0 | 514.4 | 723.9 | 44.5 | 24 | 1 5/8″ | 231 | 509 |

| 24″ | 600 | 940. 0 | 101.6 | 717.6 | 692.2 | 139. 7 | 616 | 838.2 | 50.8 | 24 | 1 7/8″ | 330 | 727 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 900lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 900LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Length Hub | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 120.7 | 22.4 | 38.1 | 31.8 | 22.4 | 82.6 | 22.4 | 4 | 3/4″ | 1.8 | 4 |

| 3/4″ | 20 | 130 | 25.4 | 44.5 | 35.1 | 27.7 | 88.9 | 22.4 | 4 | 3/4″ | 2.4 | 5.3 |

| 1″ | 25 | 149.4 | 28.4 | 52.3 | 41.1 | 34.5 | 101.6 | 25.4 | 4 | 7/8″ | 3.6 | 7.9 |

| 1-1/4″ | 32 | 158.8 | 28.4 | 63.5 | 41.1 | 43.2 | 111.3 | 25.4 | 4 | 7/8″ | 4.1 | 9 |

| 1-1/2″ | 40 | 177.8 | 31.8 | 69.9 | 44.5 | 49.5 | 124 | 28.4 | 4 | 1″ | 5.4 | 12 |

| 2″ | 50 | 215.9 | 38.1 | 104.6 | 57.2 | 62 | 165.1 | 25.4 | 8 | 7/8″ | 10.5 | 23.1 |

| 2-1/2″ | 65 | 244.3 | 41.1 | 124 | 63.5 | 74.7 | 190.5 | 28.4 | 8 | 1″ | 15.8 | 34.8 |

| 3″ | 80 | 241.3 | 38.1 | 127 | 53.8 | 90.7 | 190.5 | 25.4 | 8 | 7/8″ | 12.3 | 27 |

| 4″ | 100 | 292.1 | 44.5 | 158.8 | 69.9 | 116.1 | 235 | 31.8 | 8 | 1 1/8″ | 23.2 | 51 |

| 5″ | 125 | 349.3 | 50.8 | 190.5 | 79.2 | 143.8 | 279.4 | 35.1 | 8 | 1 1/4″ | 37.5 | 82.6 |

| 6″ | 150 | 381 | 55.6 | 235 | 85.9 | 170.7 | 317.5 | 31.8 | 12 | 1 1/8″ | 48.3 | 106 |

| 8″ | 200 | 469.9 | 63.5 | 298.5 | 101.6 | 221.5 | 393.7 | 38.1 | 12 | 1 3/8″ | 75 | 165 |

| 10″ | 250 | 546.1 | 69.9 | 368.3 | 108 | 276.4 | 469.9 | 38.1 | 16 | 1 3/8″ | 110 | 243 |

| 12″ | 300 | 609.6 | 79.2 | 419.1 | 117.3 | 327.2 | 533.4 | 38.1 | 20 | 1 3/8″ | 146 | 322 |

| 14″ | 350 | 641.4 | 85.9 | 450.9 | 130 | 359.2 | 558.8 | 41.1 | 20 | 1 1/2″ | 172 | 379 |

| 16″ | 400 | 704.9 | 88.9 | 508 | 133.4 | 410.5 | 616 | 44.5 | 20 | 1 5/8″ | 192 | 423 |

| 18″ | 450 | 787.4 | 101.6 | 565.2 | 152.4 | 461.8 | 685.8 | 50.8 | 20 | 1 7/8″ | 272 | 600 |

| 20″ | 500 | 857.3 | 108 | 622.3 | 158.8 | 513.1 | 749.3 | 53.8 | 20 | 2″ | 330 | 727 |

| 24″ | 600 | 1041 | 139.7 | 749.3 | 203.2 | 616 | 901.7 | 66.5 | 20 | 2 1/2″ | 632 | 1393 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 1500lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 1500LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Length Hub | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 120.7 | 22.4 | 38.1 | 31.8 | 22.4 | 82.6 | 22.4 | 4 | 3/4″ | 1.8 | 4 |

| 3/4″ | 20 | 130 | 25.4 | 44.5 | 35.1 | 27.7 | 88.9 | 22.4 | 4 | 3/4″ | 2.4 | 5.3 |

| 1″ | 25 | 149.4 | 28.4 | 52.3 | 41.1 | 34.5 | 101.6 | 25.4 | 4 | 7/8″ | 3.6 | 7.9 |

| 1-1/4″ | 32 | 158.8 | 28.4 | 63.5 | 41.1 | 43.2 | 111.3 | 25.4 | 4 | 7/8″ | 4.1 | 9 |

| 1-1/2″ | 40 | 177.8 | 31.8 | 69.9 | 44.5 | 49.5 | 124 | 28.4 | 4 | 1″ | 5.4 | 12 |

| 2″ | 50 | 215.9 | 38.1 | 104.6 | 57.2 | 62 | 165.1 | 25.4 | 8 | 7/8″ | 10.5 | 23.1 |

| 2-1/2″ | 65 | 244.3 | 41.1 | 124 | 63.5 | 74.7 | 190.5 | 28.4 | 8 | 1″ | 15.8 | 34.8 |

| 3″ | 80 | 266.7 | 47.8 | 133.4 | 190.5 | 25.4 | 8 | 7/8″ | 21.5 | 43 | ||

| 4″ | 100 | 311.2 | 53.8 | 162.1 | 235 | 31.8 | 8 | 1 1/8″ | 31 | 68.3 | ||

| 5″ | 125 | 374.7 | 73.2 | 196.9 | 279.4 | 35.1 | 8 | 1 1/4″ | 58.8 | 130 | ||

| 6″ | 150 | 393.7 | 82.6 | 228.6 | 317.5 | 31.8 | 12 | 1 1/8″ | 74 | 163 | ||

| 8″ | 200 | 482.6 | 91.9 | 292.1 | 393.7 | 38.1 | 12 | 1 3/8″ | 112 | 247 | ||

| 10″ | 250 | 584.2 | 108 | 368.3 | 469.9 | 38.1 | 16 | 1 3/8″ | 184 | 406 | ||

| 12″ | 300 | 673.1 | 124 | 450.9 | 533.4 | 38.1 | 20 | 1 3/8″ | 264 | 581 | ||

| 14″ | 350 | 749.3 | 133.4 | 495.3 | 558.8 | 41.1 | 20 | 1 1/2″ | ||||

| 16″ | 400 | 825.5 | 146.1 | 552.5 | 616 | 44.5 | 20 | 1 5/8″ | ||||

| 18″ | 450 | 914.4 | 162.1 | 596.9 | 685.8 | 50.8 | 20 | 1 7/8″ | ||||

| 20″ | 500 | 984.3 | 177.8 | 641.4 | 749.3 | 53.8 | 20 | 2″ | ||||

| 24″ | 600 | 1168.4 | 203.2 | 762 | 901.7 | 66.5 | 20 | 2 1/2″ | ||||

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 2500lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

DESCRIPTION OF SLIP ON FLANGE

| Pipe Normal Diam. | Outside Diameter of Flange | Diameter Bore | thickness of Flange | Diameter of Raised Face | Height of Raised Face | Diameter of Hub at Base | Length through Hub | No. of Holes | Diameter of Holes | Diameter of Bolts | Diameter of Bolt Circle | Weight |

| inch | O | C | G | X | Y | BN | BH | BD | BC | lbs. | ||

| 1/2 | 5.25 | 0.88 | 1.19 | 1.38 | 0.25 | 1.69 | 1.56 | 4 | 0.88 | 3/4 | 3.5 | 7 |

| 3/4 | 5.5 | 1.09 | 1.25 | 1.69 | 0.25 | 2 | 1.69 | 4 | 0.88 | 3/4 | 3.75 | 9 |

| 1 | 6.25 | 1.36 | 1.38 | 2 | 0.25 | 2.25 | 1.88 | 4 | 1 | 7/8 | 4.25 | 12 |

| 1 1/4 | 7.25 | 1.70 | 1.5 | 2.5 | 0.25 | 2.88 | 2.06 | 4 | 1.12 | 1 | 5.12 | 18 |

| 1 1/2 | 8 | 1.95 | 1.75 | 2.88 | 0.25 | 3.12 | 2.38 | 4 | 1.25 | 1 1/8 | 5.75 | 25 |

| 2 | 9.25 | 2.44 | 2 | 3.62 | 0.25 | 3.75 | 2.75 | 8 | 1.12 | 1 | 6.75 | 38 |

| 2 1/2 | 10.5 | 2.94 | 2.25 | 4.12 | 0.25 | 4.5 | 3.13 | 8 | 1.25 | 1 1/8 | 7.75 | 55 |

| 3 | 12 | 3.57 | 2.62 | 5 | 0.25 | 5.25 | 3.63 | 8 | 1.38 | 1 1/4 | 9 | 83 |

| 4 | 14 | 4.57 | 3 | 6.19 | 0.25 | 6.5 | 4.25 | 8 | 1.62 | 1 1/2 | 10.75 | 127 |

| 5 | 16.5 | 5.66 | 3.62 | 7.31 | 0.25 | 8 | 5.13 | 8 | 1.88 | 1 3/4 | 12.75 | 210 |

| 6 | 19 | 6.72 | 4.25 | 8.5 | 0.25 | 9.25 | 6 | 8 | 2.12 | 2 | 14.5 | 323 |

| 8 | 21.75 | 8.72 | 5 | 10.62 | 0.25 | 12 | 7 | 12 | 2.12 | 2 | 17.25 | 485 |

| 10 | 26.5 | 10.88 | 6.5 | 12.75 | 0.25 | 14.75 | 9 | 12 | 2.62 | 2 1/2 | 21.25 | 925 |

| 12 | 30 | 12.88 | 7.25 | 15 | 0.25 | 17.38 | 10 | 12 | 2.88 | 2 3/4 | 24.38 | 1300 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

For pipe fittings, please link: https://bekingpiping.com