Share this

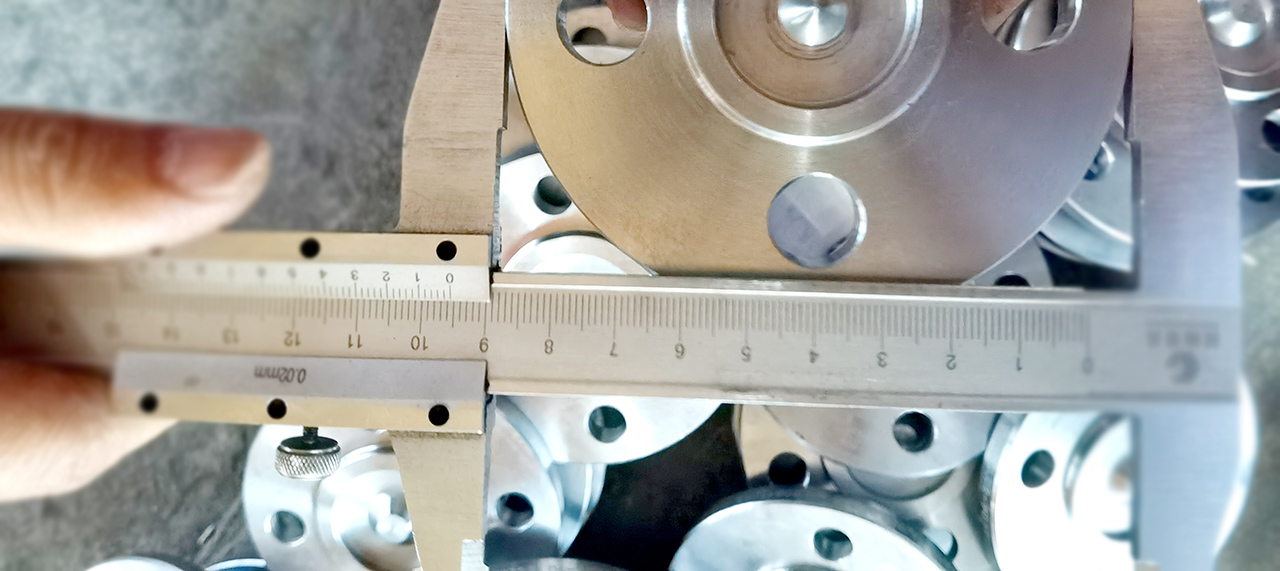

In construction, chemical industry, energy, shipbuilding and other industries, flanged pipe fittings, as a key component of the pipeline system, play an important role in connecting and fixing various pipe sections, equipment and valves. Flange fittings play an irreplaceable role in modern society due to their high sealing performance and pressure resistance. Therefore, understanding the standards and specifications of flange fittings is undoubtedly an important link that every practitioner cannot ignore.

Flange American Standard

American Standards is a popular standardization system in North America. Its standards cover a wide range and are applicable to various industries. In the American standard flange system, the standards for flanged pipe fittings mainly include ANSI and MSS-SP, which we will introduce below.

A. ANSI B16.5 standard flange and accessories: It is an American national standard, suitable for piping systems with a nominal pressure of 150Lb-2500Lb and a nominal diameter of 1/2″-24″. Used in various chemical, petroleum, natural gas, pharmaceutical, paper, food and other industries, it has the advantages of simple structure and convenient connection.

B. ANSI B16.47 large steel flange NPS 26″ to 60″: It is also an American national standard, suitable for large-diameter pipeline connections, with a nominal pressure range between 75Lb and 900Lb, suitable for oil, natural gas, shipbuilding and other fields. It has the characteristics of a wide application range and high sealing performance.

C. MSS SP-44 large steel flange NPS 22″ to 60″: also American standard, suitable for large diameter pipeline connection, widely used in large ships, offshore platforms, nuclear industry and other fields, the nominal pressure is 150Lb-2500Lb Between them, the structure of the ANSI B16.47 standard flange is basically similar, and MSS SP-44 also includes the ANSI B16.47 standard.

American standard flange pipe fittings are widely used in the international market and have the characteristics of uniform standards, rich specifications, reliable materials, and good sealing performance. When in use, it needs to be installed in strict accordance with the standard requirements and carry out strict quality control to ensure its good performance and service life.

German flange standard

The German standard (DIN) is a standardization system formulated by the German Standardization Committee. In the field of pipe flanges and fittings, there are mainly the following four German standards:

A. DIN 2501: It is the basic standard of German flanges, compatible with international standards such as ANSI, JIS, and BS. This standard applies to flange connections of various pressure and temperature classes.

B. DIN 2573: It is an ordinary flat welding flange with a protruding shape attached to the center of the flange. It is suitable for flanged pipe fittings with a nominal pressure between PN6 and PN10 and is often used in steam, air, water and other media.

C. DIN 2576: It is an ordinary flat welding flange with a protruding shape attached to the center of the flange. It is suitable for flange connections with nominal pressures between PN10, PN16, PN25, and PN40. It is often used in petroleum, chemical, electric power, etc. fields.

D. DIN 2631-2635: It is the pressure resistance standard of German flanges, including flanges, welding neck flanges, blind plates, bolt collars and other types of flanged pipe fittings. Flange joints suitable for homogeneous or loose media with nominal pressures between PN6, PN10, PN16, PN25, PN40, PN64, and PN100.

German standard flange pipe fittings are favored by users for their high quality, stable performance, and rigorous structure. When used, it needs to be selected according to the standard requirements and undergo strict quality control to ensure the safety and stability of the system.

Japanese flange standard

Japanese standards refer to the standards formulated and promulgated in Japan, which belong to a kind of international standard system. In the field of pipe flange fittings, there are mainly the following four Japanese standards:

A. JIS B2220: It is the basic standard of Japanese flanges, which are divided into four grades: 10K, 16K, 20K, and 30K. It is suitable for flange connections of various pressure levels.

B. JIS B2210-1984 Bolts and flange rings of cast iron flanges: suitable for bolts and flange rings of cast iron flanges, which are divided into three grades: 10K, 16K, and 20K, and are often used in low-pressure and low-temperature occasions.

C. JIS B2311 steel pipe flange: It is suitable for flange joints with a nominal pressure between 1.6MPa and 2.5MPa and a nominal diameter between 10A and 1000A. It is often used in petrochemical, nuclear power plants and other fields.

D. JIS B2312 steel welded pipe flange: suitable for flange joints with a nominal pressure between 1.0MPa and 2.5MPa and a nominal diameter between 10A and 500A. It is often used in petrochemical, shipbuilding, aerospace and other fields.

The above are some of the more common flange pipe fitting standards in Japanese standards. Compared with other national standards, Japanese standard flange pipe fittings have the characteristics of good sealing performance, fine manufacturing process, and good equipment completeness. They are popular in the international market. Approved quality product.

Flange standards of other countries

In addition to the flange pipe fitting standards of the four countries (China, the United States, Germany, and Japan) introduced above, the British Standard (BS) is also one of the common standards in the world. Here we introduce the standard BS 4504.

BS 4504: It is a British standard for flanged pipe fittings, suitable for flange connections with nominal pressures between PN6 and PN64 and nominal diameters between 1/2″ and 78″. This standard includes different types of flanges, such as flat welding flanges, blind plates, locking flanges, etc., which are widely used in petrochemical, construction, heating and other fields.

BS 4504 standard flange pipe fittings are famous for their fine manufacturing process, various materials and wide application range. It is compatible with European standards and can be used in conjunction with German standard DIN, French standard NF, European standard EN, etc. Metric BS 4504 standard flanges (PN flanges) and metric DIN standard flanges are interchangeable in the case of corresponding dimensions.

Non-standard flange and customized service

A. Current status and prospects of customization needs:

With the development of various industries, users pay more and more attention to the personalization and differentiation of products, and traditional standardized products can no longer fully meet their needs. Therefore, customized production has become one of the trends of modern production. Especially in the field of flanged pipe fittings, due to the different requirements of different industries and application scenarios, different piping systems need to have different characteristics such as size, model and material, so customization has become an important demand for consumers when purchasing flanged pipe fittings.

B. Customized service process:

The customized service process generally includes the following stages:

Locate customer needs: Obtain orders from customers and learn more about the specific needs of customers.

Technical solution design: According to customer needs, provide technical solutions that meet the requirements.

Production and processing: According to customer requirements, production and processing are carried out. Non-standard products require customers to provide non-standard drawings or product samples as the basis for imitation processing.

Inspection and acceptance: Inspection and acceptance are carried out according to different standards to ensure the quality and integrity of products.

Delivery logistics: After completion, arrange a reasonable logistics plan to package and deliver the product.

C. Business opportunities and challenges:

Customized service is a very important link in every industrial chain. For manufacturers of flanged pipe fittings, carrying out customized services is not only a transformation of production mode but also a new business path. However, there are also some difficulties and problems in customized services, such as unclear customer needs, technical difficulties, long production cycles, and high costs. Therefore, in order to meet customer needs, improve production efficiency, and speed up delivery cycles, manufacturers of flanged pipe fittings need to make efforts in establishing a complete industrial chain, improving productivity and technical level, strengthening the collection and analysis of market information, and improving after-sales service. To cope with market changes and industry competition.

This article introduces flanged pipe fittings and their standards and analyzes the importance and status quo of customized services in the production and market of flanged pipe fittings. Flange fittings are widely used in all walks of life, and their specifications and standards are also very rich. In the future, with the development of various industries and changes in demand, there is still a lot of room for development in the application and improvement of flange fittings.

The future trend of flange fittings will pay more attention to the high performance and safety of products. With the advancement of technology and changes in demand, flanged pipe fittings will gradually develop towards high pressure, high temperature, and high performance. At the same time, due to the changes in economic methods and the strengthening of environmental protection awareness, the flange pipe fittings industry will also develop in a green, sustainable and economical direction.

ELITE has rich experience and technical strength and can provide customers with high-quality customized services. It has advanced production equipment and a scientific management system, which can quickly respond to customer needs and carry out production, while also ensuring stable product quality and strict delivery time. ELITE is also able to provide differentiated and personalized flange fittings products that meet the needs of customers according to the requirements of different industries, different environments and different uses.