Share this

What is a flange?

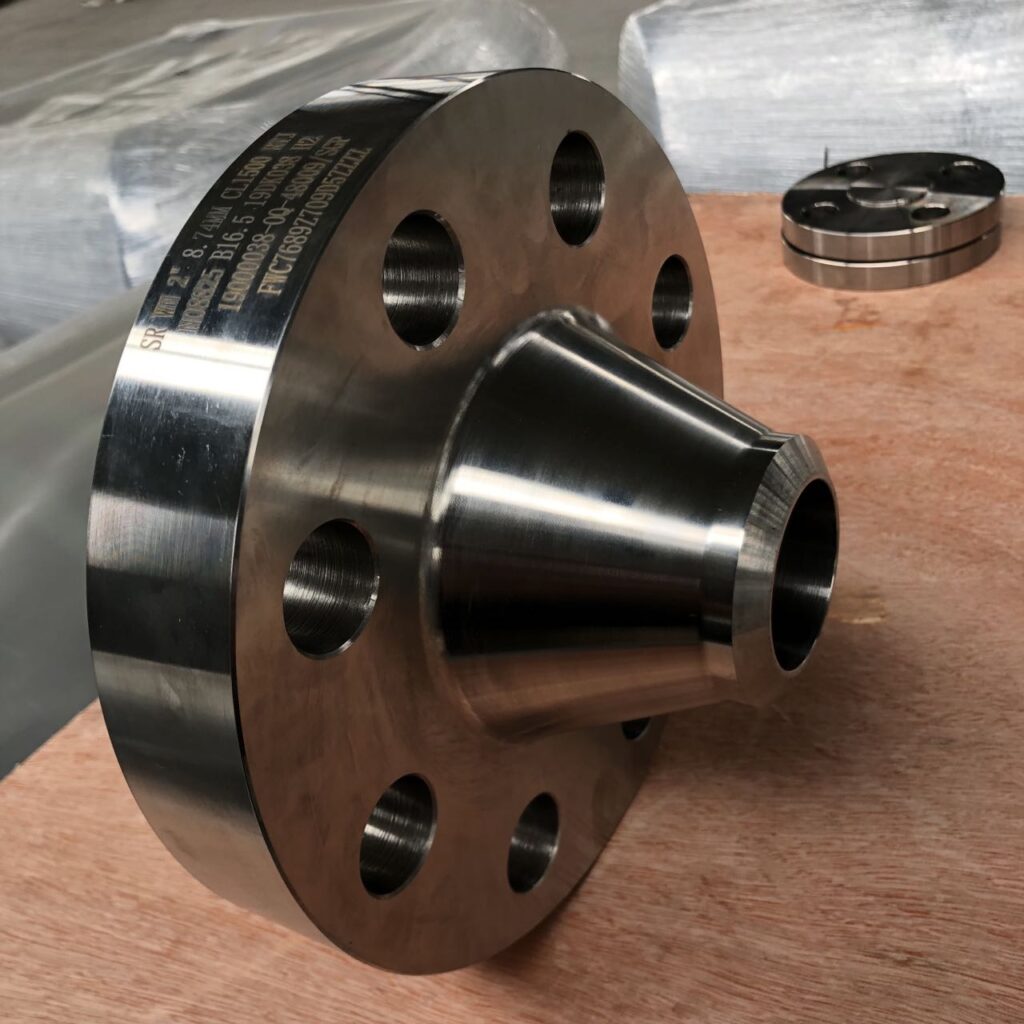

Flanges are cast or forged steel products used to connect pipes with other mechanical equipment. In the oil and gas industry, forged steel flanges are favored for their inherent strength and durability.

Flange size

The critical dimensions of pipe flanges are:

Nominal size (that is, the aperture of the flange to match the aperture of the connecting pipe)

Flange rating (specify the pressure/temperature performance of the flange, i.e. 150#, 300#, 400#, up to 2500#)

Type of flange

There are many types of pipe flanges, the standard ones are butt welding, blind plate, socket welding, lap joint, thread and so on. There are also special types of flanges such as swivel flanges, expansion/reduction flanges, and hole flanges.

Flange type

As a general rule, weld neck flanges, socket weld flanges, and socket weld flanges are used in high-pressure applications where durable flanged joints are required. Threaded flanges can be used in low-pressure piping systems if the vibration is not present.

Flange Type Code

Lap flanges are used in conjunction with short pipe ends to facilitate bolt alignment of two mating flanges or to reduce the cost of precious metal material in advanced flange joints (for example, in Inconel piping systems where the short pipe end may be connected to the pipe is Inconel, while lap flanges can be of a lower grade, saving the overall weight of the expensive Inconel material).

Flange material

The main material grades for pipe flanges are examined in another article and include:

ASTM A105 (Carbon Steel Flanges for High-Temperature Service)

ASTM A350 (Low-Temperature CS Flange)

ASTM A694 (High Production Carbon Steel Flanges for Line Pipe)

Carbon steel small flange

ASTM A182 F1 to F91 (alloy steel flanges)

ASTM A182 F304, F316, F321 (stainless steel flange)

ASTM A182 F51, ASTM A182 F53/55 (Duplex and Super Duplex flanges) and higher grades (Inconel, Hastelloy, Monel flanges).

Pipe and flange materials are of course matched (according to the ASTM pipe material selection chart).

Flanges and flange fittings shall be castings, forgings or sheet metal

The bolt material shall meet the standard requirements.

Flange materials in piping services should be suitable for welding. The carbon equivalent of the flange used should match the pipe material.

carbon steel flange

Carbon steel flanges shall not be used for service above 425 °C

High-Temperature Service: Standard carbon steel material shall be ASTM A 105, a material safe for use in temperatures from -29 °C to 425 °C.

Cryogenic service: Carbon steel flanges for service below -29 °C shall comply with the impact test requirements of ASME B 31.3. ASTM A 350-LF2 should be the standard material for cryogenic applications

High Volume Service: High-strength carbon steel flanges ASTM A694 shall meet API standards. 5L pipe grade X42 to X65.

Low Alloy Flange

Materials for low alloy steel flanges (11/4 Cr – 1/2 Mo) shall comply with ASTM A 182-F11. The material for intermediate alloy steel flanges (11/2 Cr – 5 Mo) shall be ASTM A 182-F5.

stainless steel flange

In general, butt weld flanges should match the pipe metallurgy of any material grade. However, austenitic stainless steels are interchangeable in some cases. For example, Type 347 and Type 321 stainless steel are compatible. Flanges with double marking or double class marking. For example, lower carbon grades such as 304L and 316L can be substituted for “straight” grades as long as the “L” grades meet the physical requirements of the application.

stainless steel flange

When forging pipes, butt welding flanges should be forged. When the pipe is not forged, the material of the butt welding flange shall be approved by the customer.

Non-ferrous metal pipe flanges (copper, cupronickel and aluminum) are used in marine and aerospace applications.

Flange anti-corrosion

For specific applications, flanges can be coated, painted or lined (for example, with Teflon) to increase the resistance of the metal to attack by corrosive or aggressive fluids.

When the water and H2S concentrations of in-plant service exceed the limits specified in NACE MR0175, the service shall be considered NACE service. Flanges intended for NACE service shall comply with the special requirements of NACE MR0175. Instructions for purchase should specify “NACE Services”.

ASME/EN code

The ASME B16.5 code covers flanges for pipe applications up to 24 inches in diameter, while the ASME B16.47 code covers pipe flanges over 24 inches (A and B series available).

In more detail, the following ASME standards apply to main and companion flanges in piping engineering:

ASME B16.1: This standard applies to integral cast iron flanges and blind flanges

ASME B16.5, Classes 150, 300, 600, 900, 1500 to NPS 24 and Class 2500 to NPS 12. Class 400 carbon steel flanges shall not be used

Flanges larger than NPS 24 are specified per ASME B16.47. ASME B16.47 Series A NPS 26 to NPS 60 for classes 150 to 900 replaces these flange sizes in MSS SP-44

Series B replaces API 605 for sizes NPS 26 through 60 (ASME B16.47 Series B for pipe, flanges for couplings only)

MSS SP-44 applies to steel pipe flanges with dimensions smaller than ASME B16.47 and material grades not listed in ASME B16.5

Flanges and flanges of unlisted materials not covered by the above standards shall be designed in accordance with ASME Section VIII Section 1, Appendix 2, and blind flanges shall be designed in accordance with ASME Section VIII Section 1, Section UG-34

Flange tolerances shall be in accordance with ASME B16.5 Section 7 (for flanges up to NPS 24) and ASME B16.47 (for flanges above NPS).

The EN 1092-1 specification covers pipe flanges for European piping systems (type 11 butt weld flanges, type 01 plate flanges, type 05 blind flanges, type 13 threaded flanges).

Flange marking standard

Flanges and flange joints shall be marked in accordance with MSS SP-25. The marking shall include the following: pressure rating, name, nominal pipe size, the letter “R” of the ring joint flange and the corresponding ring groove number, the letter “PL” shall precede the grade symbol, and then the material grade of the pipe, the law Flange type, the surface or wall thickness of the flange.

Flange joint

A flange joint is a connection between a pipeline and other pipeline equipment, such as another pipeline, a valve, or a pressure vessel. Piping systems require hundreds or even thousands of flange joints to function properly.

The three main components of a flanged joint are:

Two mating flanges (“main” flange and “mate” flange).

Many studs for flanges (flanges of different diameters, grades and surface finishes require different numbers and sizes of studs and nuts to seal properly);

Two gaskets, either metallic (spiral wound, ring joint, jacketed and Kammprofile) or non-metallic (non-asbestos gaskets).

Steel pipes can be welded to the flange (this is the case for weld neck, socket weld, socket and lap flanges) or screwed to the flange (threaded flange). Welded connections between pipe and flanges for high-pressure and high-temperature applications over 2 inches in diameter. Threaded connections are used in small-diameter piping systems that are not affected by mechanical forces such as expansion, vibration, contraction, and oscillation.

Flange insulation kits are also available for flange connections to protect flanges, bolts and gaskets from corrosion caused by quiescent current flowing through the pipeline (this is called “cathodic protection”).

To prevent dangerous leaks in pipelines, flange joints may only be performed by trained personnel (Standard TSE – TS EN 1591 Part 1-4, “Flanges and their joints” is the reference specification).

flange bolts

Pipe flanges should be fitted with appropriate studs and nuts. Using the correct quantity, diameter, length and material to properly seat flanges and ensure a leak-free connection is absolutely critical. Also, the studs should be tightened in the proper sequence and by applying the proper torque.

The flange bolting chart shows the exact number, diameter and length of studs required for ASME flanges of different sizes, grades and surface finishes.

How to order flanges?

The following data should be communicated to the manufacturer when ordering flanges:

Flange type (flat welding flange, butt welding flange, loose flange, threaded flange, socket welding flange, blind flange)

Flange specifications (such as national standards, chemical standards, Ministry of Machinery standards, ASME B16.5, ASME B16.47 Type A, EN 1092-1, JIS, UNI, DIN, non-standard, etc.)

Nominal Pipe Size (NPS)

Flange grade (or grade): ASME flanges range from 150 to 2500, JIS B2220 flanges and KS1503 flanges range from 5k to 30k; from PN 6 to PN 100 for Europe and Russia Standard flanges (DIN, UNI, EN 1092-1, GOST 12820 / 12821-80); 600/3, 1000/3, 1600/3, 2500/3, 4000/3 grades of SANS/SABS flanges (flanges South African standard)

Piping plans (for butt weld neck and socket weld flanges)

Flange face type (FF; RF, RTJ): according to ASME B16.5, the raised face is the standard face of the flange (different faces, such as RTJ or flat FF, must be specially ordered)

Flange surface finish (smooth, rough, concentric serrated, etc.)

Material grades (wrought carbon steel, stainless steel, duplex steel, nickel alloy steel or non-ferrous materials such as cupronickel, copper, aluminum and bronze)

For pipe fittings, please link: https://bekingpiping.com