Share this

Large flange manufacturers: The sealing failure of large flange sealing joints is mainly manifested by leakage. If it is serious, in the pipeline system and installation of various industries, if the cost is relatively high, it will lead to equipment scrapping, shutdown, casualties and serious environmental pollution. The failure of the flange joint seal will cause a lot of waste of energy and raw materials. Therefore, the petrochemical, modern petroleum, chemical, atomic energy, aerospace and other industries of flange manufacturers have put forward higher requirements for pipeline installation and sealing. The flange manufacturer connection is a detachable connector, which is a product with high sealing requirements. The key is in the sealing material, the quality of the sealing material is directly related to the sealing quality of the flange product. It can be said that although the gasket is small, it is related to the sealing failure of the flange.

Generally, large flanges have a large bearing weight and are generally not easy to deform. The most difficult thing for flange manufacturers to process is their thickness. The key is thickness. The inner diameter and outer diameter of the large flange on the production side are not a problem. The large flange is too thin to be deformed. Of course, in the production process, the deformation problem generally does not occur, nor does it occur during machining, but in the process of use is dangerous.

The large flange is cut into a plate by the middle plate, and then rolled into a circle. This is a general large flange, up to 7 meters. These flanges have a very good quality guarantee. Flange manufacturers have good density because the raw materials are in the medium plate. It is made of carbon steel, stainless steel, alloy steel and other materials.

Flange manufacturer’s production process characteristics: large flange products are welded products without threads. There are three types of large flange production processes: forging, rolling and splicing. First, cut the middle plate into suitable strips. The length of the strip depends on the size of the large flange. Then roll the coil into a circle, and the interface is tightly welded to the electrode. An X-ray spectrum test is required at the weld. The press is then reused with the press, followed by a lathe for the plumbing and chamfering process. Then combine the drilling machine with the drilling machine to drill the bolt holes.

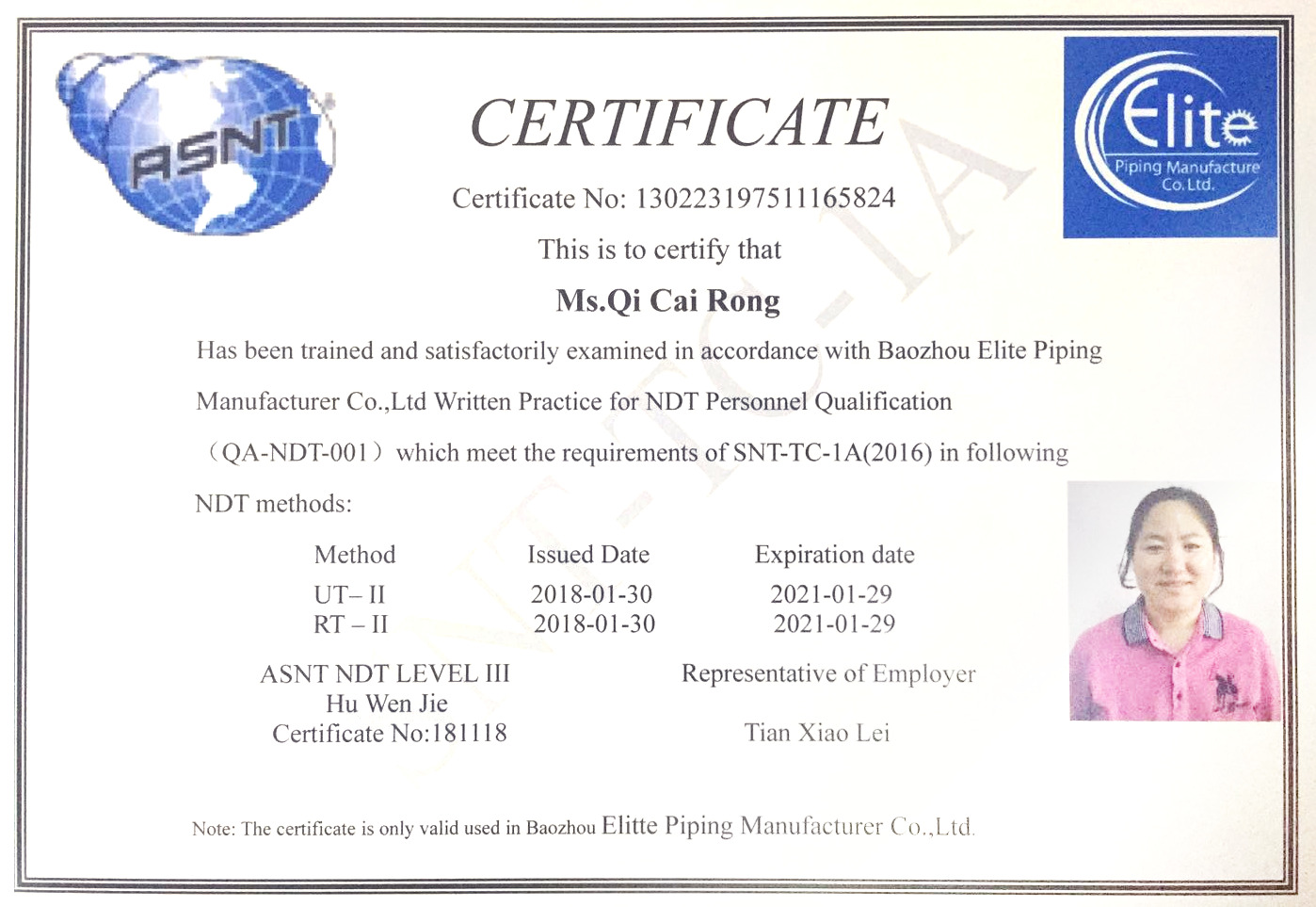

Strong inspection, testing team and their certificates

For pipe fittings, please link: https://bekingpiping.com