Share this

Large-diameter butt welding flange connections are easy to use, can withstand large pressures, and play an important role and value in use. In industrial pipelines, large flange connections are widely used and have different meanings and functions in the industry.

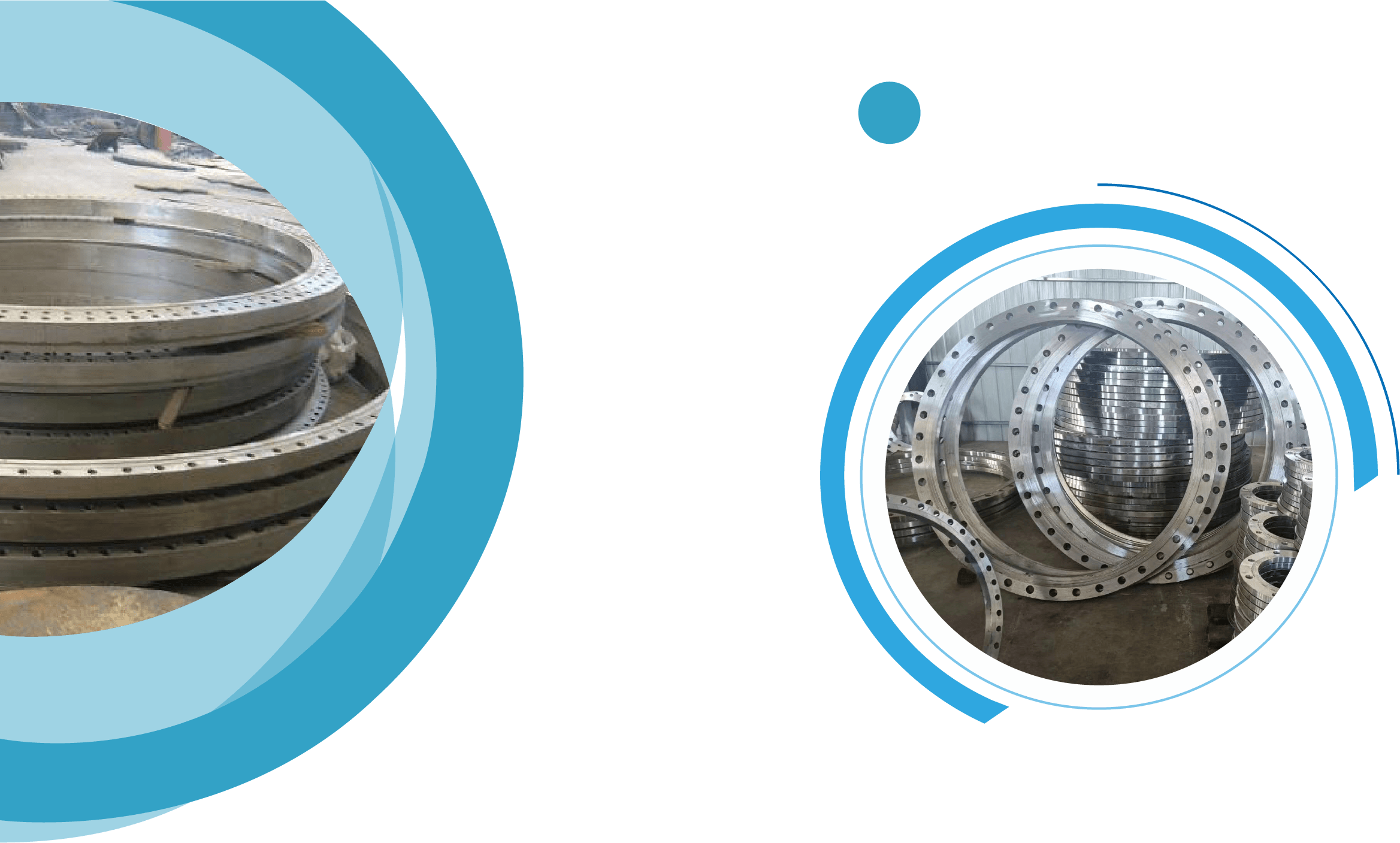

Large-diameter butt welding flanges refer to flanges that exceed the size specified by the relevant state departments, generally referring to flanges with a size above DN2000. The production of such flanges requires the construction party to provide drawings for production.

Large-diameter flanges

commonly include flat welding flanges and butt welding flanges. Flat-welded large-diameter flanges and butt-welded large-diameter flanges have different structures and scopes of use and can exhibit different features and advantages. Therefore, they should be used for different ranges to ensure that flanges play an important role…

Large-diameter flat welding flanges have poor rigidity and are suitable for occasions where the pressure is p≤4MPa; butt welding flanges, also known as high-neck flanges, have high rigidity and are suitable for occasions with high pressure and temperature. There are three types of flange sealing surfaces: flat sealing surface, suitable for occasions where the pressure is not high and the medium is non-toxic; concave-convex sealing surface, suitable for occasions with slightly higher pressure; tongue and groove sealing surface, suitable for flammable and explosive, toxic media and occasions with high pressure. Flanged pipe fittings of different properties have good product performance in different fields, and are suitable for different occasions and spaces, resulting in different effects.

The main materials are cast steel, carbon steel, stainless steel, alloy steel, forged steel, etc. The main reference parameters of the product are flange outer diameter, bolt hole center circle diameter, bolt hole diameter, bolt hole number, flange thickness, pipe outer diameter, flange inner diameter, and flange theoretical weight. There are three production processes for large butt welding flanges: forging, rolling and splicing.

If the product size is too large, it can only be formed at one time by the process of rolling and splicing without suitable raw materials and machinery. This product is generally customized through the drawings provided by the customer. Due to the large area occupied by the product, on-site assembly welding can be used at the place where the product is used. It can reduce shipping costs and reduce product quality problems during transportation.

For pipe fittings, please link: https://bekingpiping.com