Share this

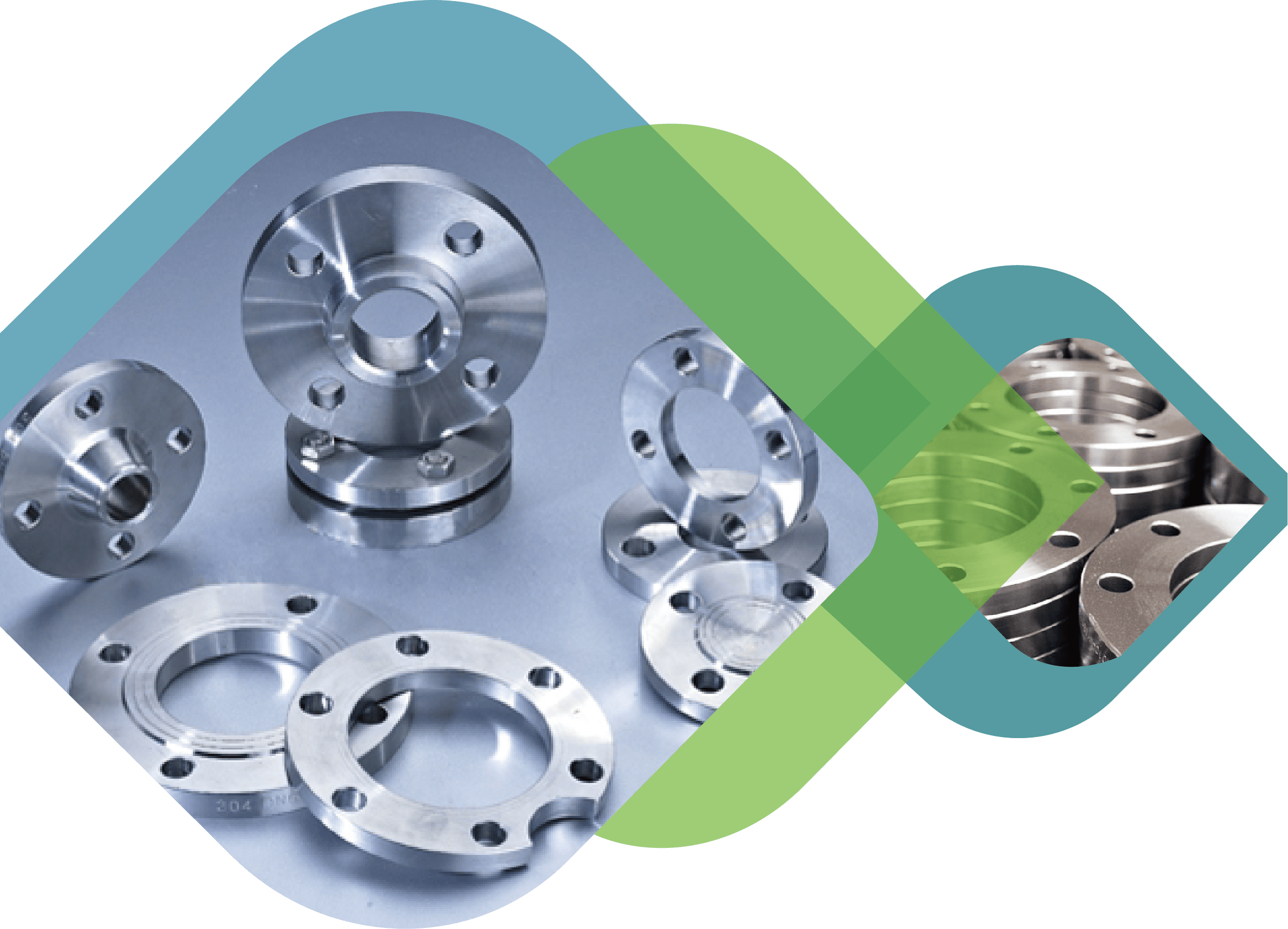

Flange, also known as flange or flange. Usually, it refers to opening several fixed holes on the periphery of a disk-like metal body for connecting other components and is widely used in various mechanical equipment and pipeline connections. Flanges are the interconnected parts between shafts and are used for the connection between pipe ends; they are also used as flanges on the inlet and outlet of equipment for the connection between two pieces of equipment, such as reducer flanges.

Classification of flanges?

1. According to the chemical industry (HG) industry standard:

Integral Flange (IF), Threaded Flange (Th), Plate Welding Flange (PL), Neck Welding Flange (WN), Neck Welding Flange (SO), Socket Welding Flange (SW) ), butt welding ring loose flange (PJ/SE), flat welding ring loose flange (PJ/RJ), lining flange cover (BL(S)), flange cover (BL).

2. According to the petrochemical (SH) industry standard:

Threaded flange (PT), butt welding flange (WN), flat welding flange (SO), socket welding flange (SW), loose flange (LJ), and flange cover (not shown).

3. According to the machinery (JB) industry standard:

Integral flange, butt welding flange, plate flat welding flange, butt welding ring plate loose flange, flat welding ring plate loose flange, flanging ring plate loose flange, flange cover.

4. According to the national (GB) standard:

Integral flange, threaded flange, butt welding flange, neck flat welding flange, neck socket welding flange, butt welding ring with neck loose flange, plate flat welding flange, butt welding ring plate loose sleeve Flange, flat welding ring plate loose flange, flanging ring plate loose flange, flange cover.

flange standard

Flanges are widely used internationally as a connector, which requires a unified standard. For example, there are mainly two standard systems for pipe flanges, namely the European pipe flange system (DIN, GB, JB, HG20592) represented by German DIN (including the former Soviet Union) and the American ANSI pipe flange represented by the United States. Pipe flange system (including ANSI, GB, HG20615). In addition, there are Japanese JIS pipe flanges, but they are generally only used for public works in petrochemical plants and have little impact internationally. Now the pipe flanges of various countries are introduced as follows:

1. European flange system

European flange system: German DIN (including the Soviet Union)

Nominal pressure: 0.1, 0.25, 0.6, 1.0, 1.6, 2.5, 4.0, 6.4, 10.0, 16.0, 25.0, 32.0, 40.0, Mpa;

Calculated diameter: 15~600mm;

Flange structure type: flat welding plate type, flat welding ring loose sleeve type, crimping loose sleeve type, butt welding crimping loose sleeve type, butt welding ring loose sleeve type, butt welding type, neck thread connection type, integral type, and flange cover;

Flange sealing surfaces include: flat surface, concave surface, concave-convex surface, tongue and groove surface, rubber ring connection surface, lens surface, and diaphragm welding surface;

The OCT pipe flange compendium standard issued by the Soviet Union in 1980 is similar to the German DIN standard.

2. American flange system

American flange system: American ANSI B16.5 “Steel Pipe Flanges and Flange Fittings”

Nominal pressure: 150psi (2.0Mpa), 300psi (5.0Mpa), 400psi (6.8Mpa), 600psi (10.0Mpa), 900psi (15.0Mpa), 1500psi (25.0Mpa), 2500psi (42.0Mpa);

Calculated diameter: 6~4000mm;

Flange structure type: strip welding, socket welding, threaded connection, loose sleeve, butt welding, and flange cover;

Flange sealing surface: concave surface, concave-convex surface, tongue and groove surface, metal ring connection surface.

3. JIS (Japanese standard) pipe flange

JIS pipe flange: generally only used for public works in petrochemical plants, it has little influence in the world, and there is no independent system in the world.

4. Flange sealing surface: flat surface, concave surface, concave-convex surface, tongue groove surface, the ring connection surface

Flange assembly

1. Before assembling the flange, the flange surface, especially the sealing surface, must be cleaned.

2. When assembling a flat welded flange, the pipe end should be inserted into 2≤3 of the thickness of the inner diameter of the flange, and then the flange and the pipe should be spot welded. If it is a horizontal pipe, the flange should be spot welded from above, and then the flange position should be checked and corrected from different directions with a 90° angle ruler so that the sealing surface is perpendicular to the centerline of the pipe, and then the second under spot welding point is correct.

3. Use a 90° angle ruler to check and correct the flange position from the left and right directions, and complete the spot welding and fixing of the flange after passing the third and fourth spot welding.

4. As far as the assembly of flange pairs is concerned, the bolt holes of the mounting flange should be aligned with the corresponding bolt holes of the fixed flange and parallel to the fixed flange, and the deviation should not be less than 1.5% of the outer diameter of each thousand flanges. And not more than 2mm.

5. When selecting the matching flange of equipment or valve parts, attention should be paid to whether the flanges of the original equipment or valve parts are consistent with the flange connection size used in the pipeline.

For pipe fittings, please link: https://bekingpiping.com